Cycolac ABS FR15U-NA1000 Natural FR UL94 V-0/5VA Rated Resin Granules

-

$2.90 / 25 - 499 kilograms

$2.50 / 500 - 999 kilograms

$2.10 / 1000 - 9999 kilograms

$1.90 / >=10000 kilograms - 25 kilograms

- Shenzhen Samtion Chemical Co., Ltd.

- Guangdong, China

- Mr C

Product Detail

| 94V-0 Flame Rating(3): | 1.49 | 94-5VA Rating(3): | 2.79 |

| port: | Guangzhou | Origin: | Guangdong, China |

| The melt flow rate: | 7 | model: | FR15U-NA1000 |

| Supply capacity: | 10000 bags per day | brand: | West Corac |

| Packaging Details: | 25kg/bag | feature: | Flame retardant ABS with excellent indoor UV performance |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram | color: | For all colors except blue and green |

Product Description

Seclek ABS FR15U

Flame retardant ABS has excellent indoor ultraviolet performance and excellent processing performance. UL94 V-0/5VA rated. Improve UL RTI rating (90-85-90) For all colors except blue and green (60-60-60).

Cycolac ABS resin is a terpolymer blend of an amorphous thermoplastic copolymer of acrylonitrile and styrene with an elastomeric component such as polybutadiene or a butadiene polymer. By varying the ratios of these three monomers, Cycolac resins can provide a wide range of performance properties to meet various end-use requirements.

Product parameters

Mechanical | value | unit | standard | |

Tensile stress, yld, Type I, 5 mm/min | 37 | MPa | ASTM D638 | |

Tensile stress, brk, type I, 5 mm/min | 30 | MPa | ASTM D638 | |

Tensile Strain, yld, Type I, 5 mm/min | 2.4 | % | ASTM D638 | |

Tensile strain, brk, type I, 5 mm/min | number 17 | % | ASTM D638 | |

Tensile modulus, 5 mm/min | 2060 | MPa | ASTM D638 | |

Bending stress, yld, 1.3mm/min, 50mm span | 67 | MPa | ASTM D790 | |

Flexural modulus, 1.3mm/min, 50mm span | 2340 | MPa | ASTM D790 | |

Tensile stress, yield strength, 50 mm/min | 41 | MPa | ISO527 | |

Tensile Strain, Break, 50 mm/min | 21.9 | % | ISO527 | |

Tensile modulus, 1 mm/min | 2210 | MPa | ISO527 | |

Bending Stress, Yield Strength, 2 mm/min | 63 | MPa | ISO178 | |

Flexural modulus, 2 mm/min | 2260 | MPa | ISO178 | |

Influence | value | unit | standard | |

Izod impact, notched, 23°C | 213 | J/m | ASTM D256 | |

Instrumented Total Impact Energy, 23°C | 28 | J | ASTM D 3763 | |

Izod impact, notched 80*10*4 +23°C | 12 | kJ/square meter | ISO 180/1A | |

hot | value | unit | standard | |

Vicat softening temperature, rate B/50 | 93 | ℃ | ASTM D 1525 | |

HDT, 0.45 MPa, 3.2 mm, unannealed | 86 | ℃ | ASTM D648 | |

HDT, 1.82 MPa, 3.2mm, unannealed | 75 | ℃ | ASTM D648 | |

CTE, -40°C to 40°C, Flow | 9. E-05 | 1/℃ | ASTM E 831 | |

CTE, -40°C to 40°C, xflow | 9.18E-05 | 1/℃ | ASTM E 831 | |

Vicat softening temperature, rate B/50 | 92 | ℃ | ISO 306 | |

Relative Temperature Index, Electrical | 90 | ℃ | UL746B | |

relative temperature index, mechanical shock | 85 | ℃ | UL746B | |

Relative temperature index, no mechanical influence | 90 | ℃ | UL746B | |

physical | value | unit | standard | |

proportion | 1.19 | - | ASTM D 792 | |

Mold Shrinkage, Flow, 3.2 mm | 0.5 - 0.7 | % | method | |

Melt Flow Rate, 230°C/3.8 kgf | 3.3 | g/10min | ASTM D 1238 | |

Melt viscosity, 200°C, 1000 sec-1 | 3200 | balance | ASTM D 3825 | |

density | 1.19 | g/cubic centimeter | ISO 1183 | |

Melt Flow Rate, 220°C/5.0 kg | 7 | g/10min | ISO 1133 | |

Melt Volume Rate, MVR, 220°C/10.0 kg | 40 | Cubic centimeters/10 minutes | ISO 1133 | |

electric | value | unit | standard | |

Arc Resistance, Tungsten {PLC} | 7 | PLC code | ASTM D 495 | |

Hot wire ignition {PLC) | 2 | PLC code | UL 746A | |

High voltage arc tracking rate {PLC} | 4 | PLC code | UL 746A | |

Melt flow rate, 265°C/2.16kg | 10 | g/10min | ASTM D 1238 | |

Source GMD, last updated: 01/05/2000 | ||||

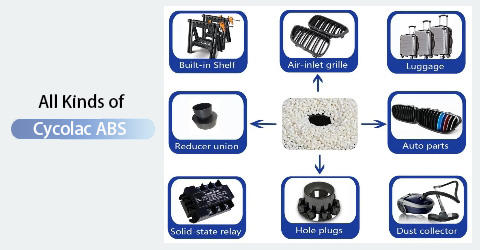

Cyclac ABS All kinds of brands and all kinds of grades Contact us for a free quote | medical biological equipment |

Electroplating process | |

non-flammable | |

high heat resistance | |

extrusion process | |

visual effects plastic |

VIEW MORE

Related Products

-

Factory price flame retardant high impact ABS Polylac PA-777E plastic raw material virgin ABS particles extrusion grade particles

port: Tianjin Port, Qingdao Port, Shanghai Port, Ningbo Port grade: Injection molding grade. extrusion grade pack: 25kg/bag Packaging details: 1.25kg per pack, paper plastic bag 2. All packaging can be customized. 3. Inner packaging plastic bag, good quality brand: Guanghong payment terms: Letter...... -

Molded ABS Plastic Sheets for Thermoforming and Vacuum Forming

Material: ABS Place of origin: China, Guangdong (Mainland) brand: ZN, ZN surface: smooth, rough or textured Package preview: Minimum order quantity: 1 ton Standard size: 1.22*2.44m Supply capacity: 40 tons per day port: Guangzhou FOB price model: ABS Place of origin: Chinese mainland) payment...... -

asa granules asa plastic granules asa granules flame retardant UL94 V0

Package preview: port: Shanghai grade: virgin model: ASA FR K01 non-flammable: V0 brand: Cipaoli application: Household appliances, automobiles, new energy industries delivery time: 1-2 weeks Supply capacity: 50000 kg per year brand: Cipaoli color: natural color, black or customized Certificate:...... -

POP 6502, plastic masterbatch with transparent polyolefin granules with pop plastomer

port: Shanghai payment terms: L/C, D/P, D/A, T/T brand: Runhongyuan Company brand: Runhongyuan Company product name: POP 6502 model: 6502 Package: 25kg rubber bag MOQ: 25 kg color: transparent feature: injection molding Material: Pop music Key words: food contact grade Package preview: Origin:...... -

Heat Resistant Zhenjiang Chimei ABS D-1000 Granules Native Natural Abs For Extruding Abs Plastic Raw Materials

feature: Tremendous influence Origin: Zhenjiang, Zhejiang payment terms: wire transfer Package: 25kg/bag Package preview: Packaging Details: 25kg/bag color: natural color usage: Injection products model: D-1000 Material: Acrylonitrile butadiene styrene plastic type: Raw Granular Resin port: Ningbo..... -

Milky white high rigid raw material ABS Changke 1725 plastic particles Changke ABS 1725

country of origin: Fangchenggang, China port: Shanghai Ningbo payment terms: other Origin: Fangchenggang, China Model: ZJ-A001 Packaging Details: 25kg/bag Package preview: model: ZJ-A001 External: transparent particles brand: regulars Material: ABS Product Description Model ZJ-A001 brand Chang Ke...... -

High quality PP/PE/HDPE/LDPE/PVC/ABS/EVA/PC resin

Packaging Details: 25kg/PPO woven bag or at your disposal Certificate: TDS MSDS ROHS model: Polycarbonate ABS Package preview: Material: Virgin ABS Granules appearance: White particle ABS application: Industrial grade, electronic grade payment terms: L/C, Western Union, T/T application: car port:...... -

Best Quality ABS Black and Used Computer Scrap

Material: Acrylonitrile butadiene styrene plastic Origin: U.S. application: ABS waste payment terms: Western Union, T/T, MoneyGram port: worldwide grade: Injection grade Packaging Details: At the buyer's request color: Nature Supply capacity: 100,000 tons per week MOQ: 18 tons model: PC ABS, ABS...... -

ABS alloy material white engineering plastic particles price discount low price recycled hip grain resin hip glue

color: white Package preview: Name: Masterbatch usage: 1%-5% Supply capacity: 100000 cases per day model: 168 port: Tianjin Package: 25kg/bag payment terms: L/C, Western Union, D/P, D/A, T/T Origin: Shandong China Material: plastic raw material pellets appearance: small particles product name:...... -

LG ABS HI121H has well balanced mechanical properties injection molding grade abs acrylonitrile butadiene styrene

payment terms: L/C, T/T model: HI-121H, HY-NINA-10158 brand: high Origin: Hebei china grade: Injection grade shape: particle Package preview: application: car Certification: Material Safety Data Sheet Supply capacity: 50000000000 kg per day color: Nature type: 100% virgin material Material:......