Widely used real carbon fiber cloth, metal wire plain color carbon fiber cloth

- $10.00 / >=50 square meters

- 50 square meters

- Haining Zhengdan Textile Co., Ltd.

- Zhejiang, China

- Ms ella ella

Product Detail

| place of origin; place of origin: | Zhejiang, China | Material: | 100% carbon fiber |

| port: | Shanghai | Craft: | weave |

| Certification: | ASTM | feature: | Wear-resistant, waterproof, high-strength |

| Product Category: | carbon fiber cloth | payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram |

| width: | 100-150CM, 47/48" | Packaging Details: | carton |

| pack: | carton | Key words: | carbon fiber fabric |

| length: | 100 m/roll | thickness: | very light |

| product name: | Widely used real carbon fiber fabric, metal wire | Supply capacity: | 10000 square meters/month |

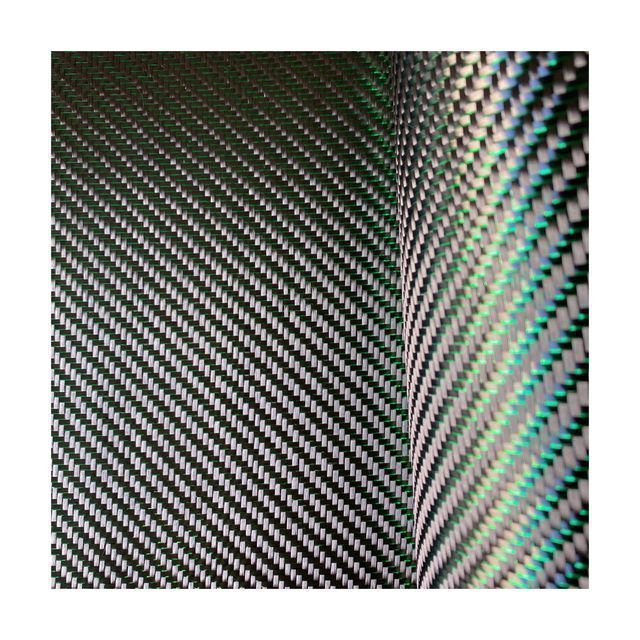

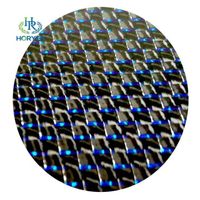

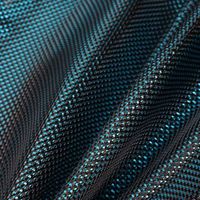

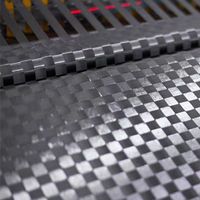

| pattern: | solid | Weave: | 3K twill / 3K plain weave |

| Application areas: | car car | brand: | Zhengdan |

| type: | 1k 3k 6k 12k | color: | black |

| usage: | Protect | Packaging Preview: | |

| style: | Twill,Plain,Hexagon,Jacquard,Other | use: | Luggage, Industry, Umbrella, Sportswear, Automobile, Military Industry, Fashion Accessories-Luggage |

| Supply Type: | stock item | model: | ZD3K240 |

| weight: | 200gsm-240gsm |

Product Description

carbon fiber fabric

1K means 1 carbon yarn contains 1000 filaments, 2K means 2000 filaments, and so on. We have 1K/3K/6K/12K carbon fiber fabrics.

Two-way carbon fiber fabrics are available in plain weave and twill weave, and are available in 120gsm, 140gsm, 200gsm, 240gsm, 280gsm, 320gsm, 400gsm, 480gsm, and 640gsm.

Some commonly used weave types are twill, plain and satin. Compared with traditional materials, carbon fiber fabrics have many advantages such as high stiffness, high tensile strength, light weight, high temperature resistance, and low thermal expansion. These keep the weight down considerably. Meanwhile, carbon fiber fabrics are compatible with a variety of resin systems, including epoxy, polyester, and vinylester resins.

It has light weight, high strength, high modulus, fatigue resistance, heat resistance, corrosion resistance, chemical resistance,

Electrical conductivity, X-ray penetration, carbon fiber fabrics are mainly used in aircraft, tail and body: car engines,

Syncs, canopies, bumpers, trims; bike racks, tap bats, stereos, kayaks, skis, various models, skeletons, building reinforcements, watches, pens, bags, etc.

Two-way carbon fiber fabrics are available in plain weave and twill weave, and are available in 120gsm, 140gsm, 200gsm, 240gsm, 280gsm, 320gsm, 400gsm, 480gsm, and 640gsm.

Some commonly used weave types are twill, plain and satin. Compared with traditional materials, carbon fiber fabrics have many advantages such as high stiffness, high tensile strength, light weight, high temperature resistance, and low thermal expansion. These keep the weight down considerably. Meanwhile, carbon fiber fabrics are compatible with a variety of resin systems, including epoxy, polyester, and vinylester resins.

It has light weight, high strength, high modulus, fatigue resistance, heat resistance, corrosion resistance, chemical resistance,

Electrical conductivity, X-ray penetration, carbon fiber fabrics are mainly used in aircraft, tail and body: car engines,

Syncs, canopies, bumpers, trims; bike racks, tap bats, stereos, kayaks, skis, various models, skeletons, building reinforcements, watches, pens, bags, etc.

Specification

type | Reinforcing yarn | weave | Fiber count (10mm) | Weight (g/m²) | Thickness(mm) | Width (mm) | ||||

warp | weft | end of warp | weft end | |||||||

ZD-1K-P | 1K | 1K | clearly | 9 | 9 | 120 | 0.16 | 1000-1500 | ||

ZD-1K-T | 1K | 1K | Twill | 9 | 9 | 120 | 0.16 | 1000-1500 | ||

ZD-1K-P | 1K | 1K | clearly | 10.5 | 10.5 | 140 | 0.17 | 1000-1500 | ||

ZD-1K-T | 1K | 1K | Twill | 10.5 | 10.5 | 140 | 0.17 | 1000-1500 | ||

ZD-3K-P | 3K | 3K | clearly | 5 | 5 | 200 | 0.30 | 1000-1500 | ||

ZD-3K-T | 3K | 3K | Twill | 5 | 5 | 200 | 0.30 | 1000-1500 | ||

ZD-3K-P | 3K | 3K | clearly | 6 | 6 | 240 | 0.32 | 1000-1500 | ||

ZD-3K-T | 3K | 3K | Twill | 6 | 6 | 240 | 0.32 | 1000-1500 | ||

ZD-3K-P | 3K | 3K | clearly | 7 | 7 | 280 | 0.34 | 1000-1500 | ||

ZD-3K-T | 3K | 3K | Twill | 7 | 7 | 280 | 0.34 | 1000-1500 | ||

ZD-6K-P | 6K | 6K | clearly | 4 | 4 | 320 | 0.38 | 1000-1500 | ||

ZD-6K-T | 6K | 6K | Twill | 4 | 4 | 320 | 0.38 | 1000-1500 | ||

ZD-6K--P | 6K | 6K | clearly | 5 | 5 | 400 | 0.42 | 1000-1500 | ||

ZD-6K-T | 6K | 6K | Twill | 5 | 5 | 400 | 0.42 | 1000-1500 | ||

ZD-12K-P | 12K | 12K | clearly | 2.5 | 2.5 | 400 | 0.46 | 1000-1500 | ||

ZD-12K-T | 12K | 12K | Twill | 2.5 | 2.5 | 400 | 0.46 | 1000-1500 | ||

ZD-12K-P | 12K | 12K | clearly | 3 | 3 | 480 | 0.52 | 1000-1500 | ||

ZD-12K-T | 12K | 12K | Twill | 3 | 3 | 480 | 0.52 | 1000-1500 | ||

ZD-12K-T | 12K | 12K | Twill | 4 | 4 | 640 | 0.64 | 1000-1500 | ||

application

1. Aerospace: fuselage, rudder.

2. Sports equipment: auto parts, fishing rods, baseball bats, sleds, speedboats, badminton rackets, etc.

3. Industry: engine parts, concert structural reinforcements, fan blades, drive shafts, etc.

4. Fireproof: suitable for the production of fireproof clothing for the military, fire protection, steel mills, etc.

2. Sports equipment: auto parts, fishing rods, baseball bats, sleds, speedboats, badminton rackets, etc.

3. Industry: engine parts, concert structural reinforcements, fan blades, drive shafts, etc.

4. Fireproof: suitable for the production of fireproof clothing for the military, fire protection, steel mills, etc.

Product display

VIEW MORE

Related Products

-

Quality Supplier Prepreg OEM Carbon Fiber Moldings Carbon Fiber Molding Custom Carbon Fiber Parts

Brand Name: A winner thickness: Customized, lightweight surface: Twill/Plain/Forged/Customized Color Product Type: Carbon fiber cloth feature: Wear-resistant, waterproof, flame-retardant, non-conductive Applicable people: Women, Men Payment Terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram...... -

Autoclave Molded Parts OEM Carbon Fiber Parts Custom Molded Carbon Fiber Parts Special Shaped Carbon Fiber Parts

pattern: 3k Supply capacity: 10,000 pieces per month thickness: Customized and lightweight For people: so gay width: custom made surface: Twill/plain/forged/customized color Product Category: carbon fiber cloth process: Forming/vacuuming Supply type: Made to order feature: High...... -

Factory OEM Custom CNC Machining Mold Making Carbon Fiber Auto Parts Low Price

payment terms: L/C, Western Union, D/P, D/A, T/T, Paypal Finish: 1.5K 3K Matt/Glossy/UD Material: 100% carbon fiber, 100% carbon fiber use: Bags, Industrial, Blankets, Felt, Shoes, Umbrellas, Luggage, Accessories, Bags, Purses & Handbags, Crafts, Outdoors, Automotive, Outdoor Umbrellas, Outdoor...... -

High Quality Colored Carbon Fiber Cloth Reflective Carbon Fiber Cloth

For people: Ladies, Men, Girls, Boys, None pattern: stripe model: FZ-carbon fiber cloth Process: to weave Product Category: carbon fiber cloth payment terms: L/C, Western Union, T/T, MoneyGram, PayPal Packaging Details: Carbon fiber wire fabric packed in carton or according to customer's...... -

Auto parts custom round carbon fiber intake pipe

feature: Wear-resistant/waterproof/anti-UV/heat insulation, wear-resistant, waterproof, anti-static, heat insulation, waterproof, anti-ultraviolet Physical properties: high strength low weight Process: knitted Serve: Carbon fiber CNC cutting, processing and forming products brand: U area pattern:...... -

High strength blended purple carbon fiber fabric cloth custom purple carbon fiber price jacquard 3k carbon fiber blended fabric

model: purple carbon fiber port: Ningbo, Shanghai, Tianjin, Shenzhen OEM/ODM: carbon fiber material payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram width: 1m, 100-1000mm feature: Wear-resistant and waterproof Packaging Details: carton OEM: Accept OEM service supply type: Inventory...... -

Blue Red Silver Metal Wire T300 Carbon Fiber Fabric Reflective Woven Carbon Fiber Fabric Plain 200g Carbon Fiber Fabric

thickness: medium weight use: Building reinforcement, industry, craft model: Influence Package preview: payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram Serve: OEM ODM customization For people: so gay style: Twill, Plain color: blue expiration of pay: TT width: Contact us for options...... -

OEM parts development for custom carbon fiber molding

delivery time: 7-15 days Origin: Guangdong, China feature: Wear-resistant, waterproof, heat insulation, flame retardant, anti-ultraviolet surface: Twill/plain/forged/custom color payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram Supply capacity: 10000 pieces per month Process: to weave...... -

30cm/40cm/50cm/1m/1.5m Width 3k Weave Carbon Fiber Fabric 2x2 Twill 240 Gsm 3k 240g Twill Carbon Fiber Fabric

model: Influence Product Category: carbon fiber cloth product name: carbon fiber cloth width: 1m/customized application: building reinforcement weight: 90-600g pattern: solid payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram Origin: Zhejiang, China sample: usable Packaging Details: carton.... -

carbon fiber spread traction fabric

thickness: 0.12-0.8mm Supply capacity: 3000 meters per week use: Bags, Industrial, Shoes, Helmets, Reinforcement, Decoration Weave: 3K twill/3K plain color: bright carbon black product name: 3k carbon fiber cloth Material: 100% carbon fiber pattern: Plaid port: Shanghai weight: 100g, 200g feature:.....