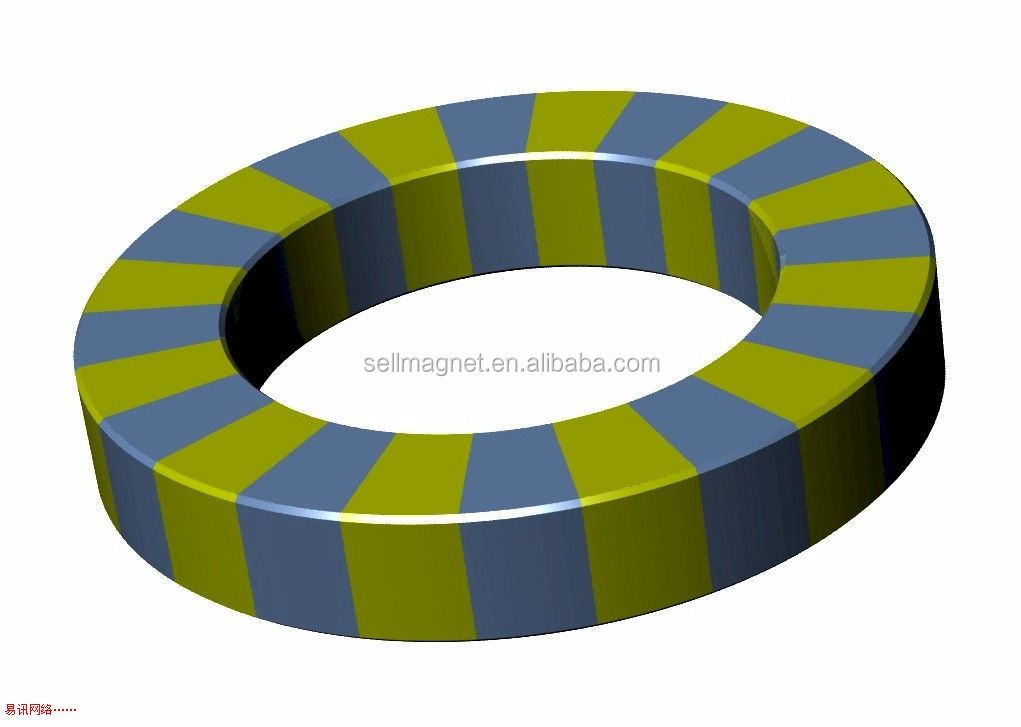

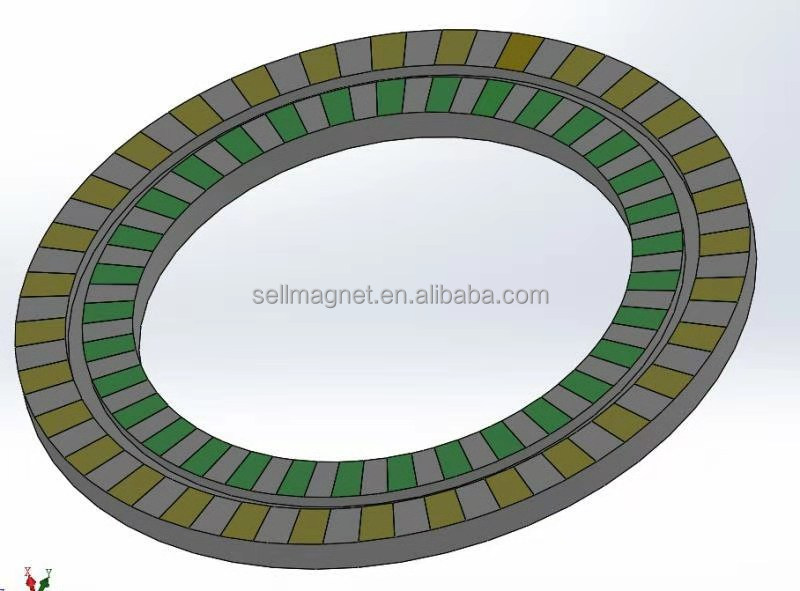

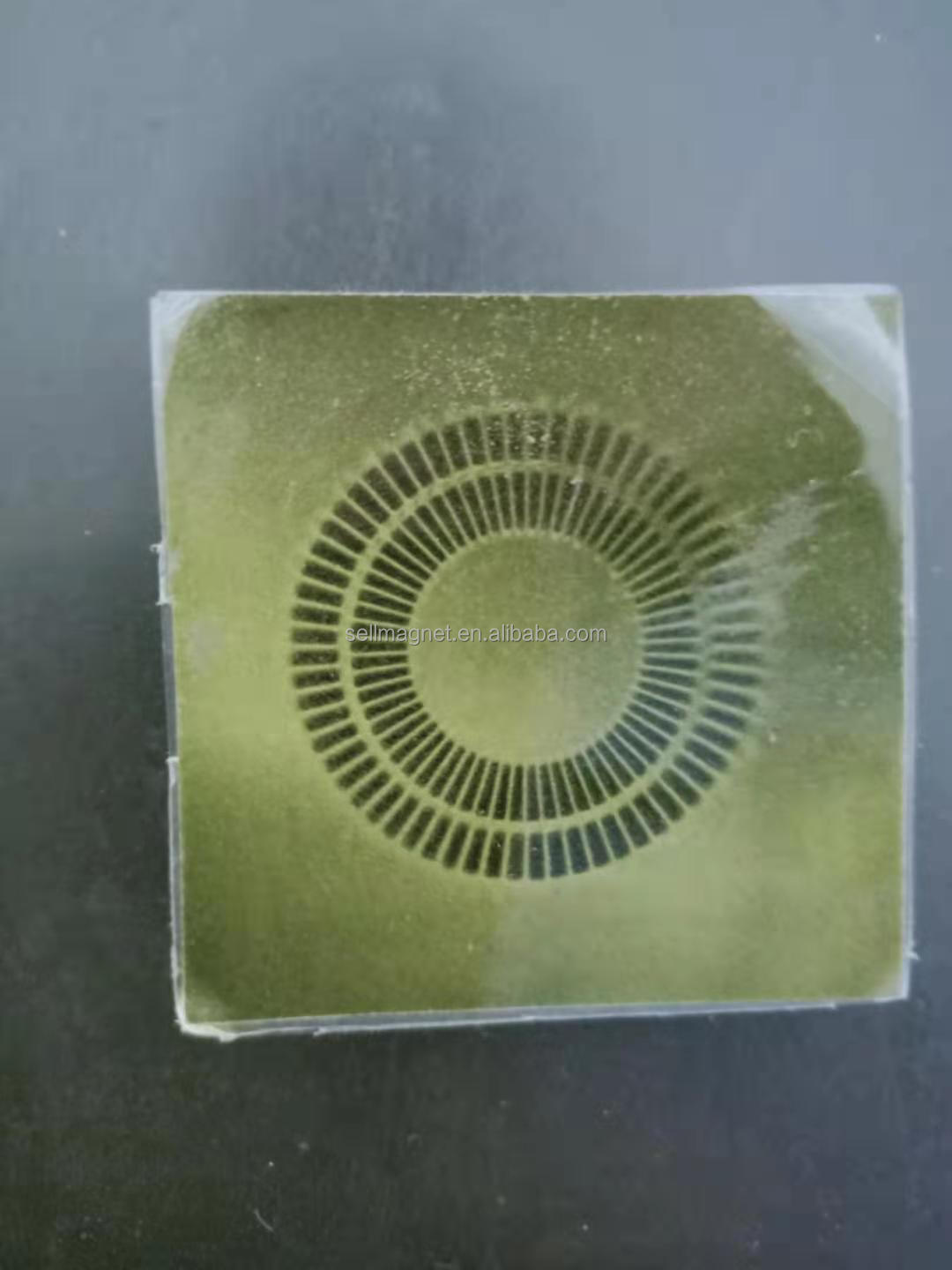

64-pole 128-pole 32-pole 24-pole 256-pole sensor encoder multi-pole magnetized neodymium magnet multi-pole ring magnet

- $0.50 / >=10 pieces

- 10 pieces

- Chengdu Amoeba Magnetic Co., Ltd.

- Sichuan, China

- Ms Alizee Zhang

Product Detail

| Synthetic: | Neodymium magnet | port: | Shenzhen Shanghai Ningbo |

| Rod width: | 1.3 mm 2 mm 0.92 mm 1.08 mm | Advantage: | Please contact us directly to protect our designs |

| Magnet pole: | 32-pole, 128-pole, 64-pole, 256-pole, 36-pole, 360-pole multi-pole | Place of origin: | Zhejiang, China |

| Packaging details: | Packaging: carton express packaging, air shipping across magnetic packaging, sea shipping packaging, | Applications of multipolar magnetization: | Can be automotive sensors, encoders, compressors, etc. |

| type: | Absolute rotary encoder magnet, permanent | Supply capacity: | Annual output 300 tons |

| tolerant: | +/-0.08,±1% | grade: | NdFeB multipolar magnet |

| delivery time: | 8-14 days | custom made: | Supportable |

| shape: | ring | Processing services: | Bending, welding, uncoiling, cutting, punching, forming |

| payment terms: | L/C, Western Union, T/T, MoneyGram, PayPal | application: | Industrial magnets |

Multi-pole magnetized encoder magnets are our advantage, welcome direct inquiries.

Largest multi-pole ring magnet

Amoeba Magnets offer all typesMagnet solutions.

Our advantages are high technology, high standards, special magnets,

Custom magnets etc.

Here is a small selection of our technology advantage magnets

(Common simple magnets are not in the list below).

Permanent magnets:

Encoder magnet

Unipolar/1 pole magnetized/3 pole magnet/5 pole magnet

tilt magnetization

multipole magnetization

Radial magnetization

Magnetic drive

Manganese zinc ferrite magnet processing

Magnetic gears (replacing traditional gears)

Large size magnet/small size magnet

Special shaped irregular magnets

Magnetic separator rod plate 12000gs 17000 Gauss

5 tons 5000kg lifting magnet (rated lifting capacity)

450mm suspension height (conveyor belt suspension magnet)

Various magnetic powders

magnetized water

600℃ high temperature resistant magnet

dielectric magnet

Tight and precise tolerances

The tolerance of NdFeB sintered magnets can meet +-0.01mm

(Industrial average tolerance is +-0.05)

Level N35-N56

5400 Gauss NdFeB magnet

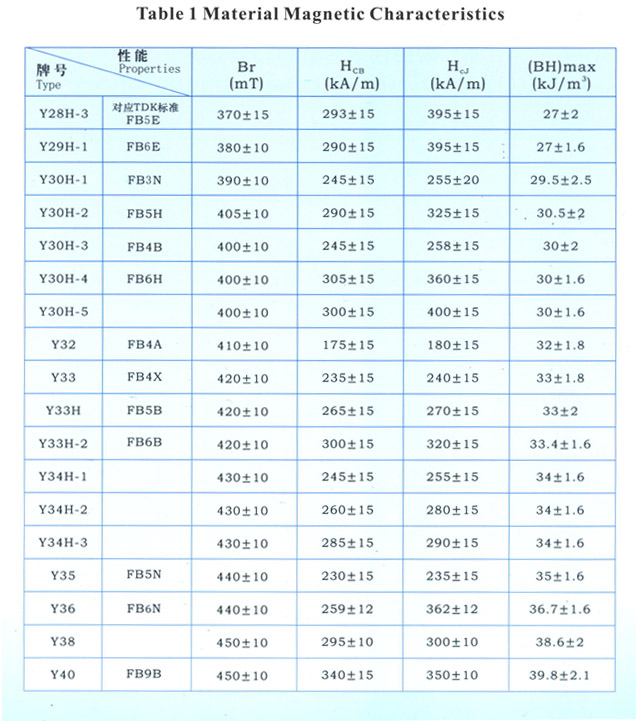

Y30-Y46 grade ferrite magnet

C8-C15 ceramic magnet

various shapes

Magnetic assembly equipment tools

High power magnets, alnico magnets, bonded NdFeB magnets at competitive prices

Soft magnet:

Produce CSC cores at competitive prices

Various soft magnetic, iron silicon aluminum, MPP, iron powder,

Mega flux, high flux, ferrite core, including KDM, etc.

Low magnetic permeability materials comply with American and Korean standards,

We can make some special cores that no one else can make.

Custom soft magnetic cores, inductors and transformers

Ferrite magnets, also known as ceramic magnets, were formulated by Phillips of the Netherlands in the 1950s. The main raw material used to make ferrite magnets is very cheap - iron oxide, commonly known as "rust"! Due to their low cost, they are the most commonly used permanent magnets even today.

Advantages of ferrite magnets

- Cheap but powerful; a good balance between strength and affordability

- Not easy to degauss

- If necessary, multi-pole magnetization can be used.

- Does not rust

1. We provide high-precision magnets such as samarium cobalt, neodymium iron boron, alnico and ferrite.

There are also soft magnetic cores, magnetic plates, pot magnets, cranes, magnetic couplings, iron-silicon-aluminum magnets, rubber magnets, injection molded magnets, etc.

2. Reply to your inquiries and emails within 18 hours. For urgent matters, please feel free to call us.

3. Customize, design and manufacture various magnets at reasonable prices.

4. We deliver goods in a timely manner and track the goods throughout the process until they arrive.

5. Samples are available at any time, try to provide molds yourself.

6. Always provide quality, friendly service.

We will help you process your order. Typically we will ask for the following information.

• 1) Type and grade of material required (magnetic).

• 2) Dimensions and shapes (if any), sketches or drawings with dimensions and tolerances.

• 3) Maximum operating temperature.

• 4) Is it delivered magnetized or unmagnetized? Magnetization direction?

• 5) Required quantity.

• 6) Coating/plating required (if any)

• 7) Information on magnet applications.

Related Products

-

3600LB Powerful Pull Power Optimum 360 Degrees Fishing Magnets for Magnet Fishing Includes Strong Neodymium N52 Magnets

delivery time: 7-15 days application: industrial magnet Material: Permanent magnet + 304 stainless steel Magnetic direction: thickness coating: Nickel Copper Nickel payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram, Payple Origin: Zhejiang, China shape: Pot/Cup Shape Supply capacity:...... -

Advanced Technology China Wholesale Buy Permanent Magnets

model: NdFeB magnet Packaging Details: The neodymium magnets are put into a white box, the size of the box is 150x100x50mm, 8 boxes per carton. The size of the carton is 370x260x150mm. If it is shipped by air, it will be packed in metal plate heat insulation. Gross weight will be 2.5 -3 kg heavier..... -

Exquisite appearance and reasonable price, NdFeB magnet N50 2X1x1 2 NdFeB strong block magnet NdFeB magnet

Material: NdFeB Class BH: N52 or custom N28 to N54 (NM-EH ) application: industrial magnet payment terms: L/C, T/T, Western Union, Paypal coating: Nickel plating (Ni-Cu-Ni-Au), Zn, Expoy, Silver, others Leading time: 7-25 days tolerant: +/- 0.05mm, others type: Everlasting size: customer request...... -

Modern Roman Design Low Price N52 Diameter Magnet Ring Magnet

sample: usable Material: NdFeB grade: rare earth Processing services: to cut Origin: Zhejiang, China size: customer request payment terms: L/C, T/T, Western Union, Paypal Magnetic direction: Thickness, Axial, Radial, Diameter, Multipolar brand: YH magnet project name: N52 neodymium magnet Class BH:.... -

12000gs 15000 17000Gauss Super Strong Neodymium Magnetic Separator Bar/Filter/Tube/Rod/Sieve/Hopper/Drawer/Grate SS304

application: Metal detection and separation, iron removal, etc., industrial magnets payment terms: L/C, Western Union, T/T, MoneyGram, PayPal Synthetic: NdFeB magnet + stainless steel sleeve Surface treatment: SS316/SS304 tolerant: ±1% Text printing: usable Maximum working temperature: 180°C Supply.... -

Super Strong Magnet Target Neodymium Permanent Block N35 N52 Rectangular Block Neodymium Ndfeb Rare Earth Magnetic Block

port: Shenzhen tolerant: 0.05mm ~ 0.1mm, ±3% Synthetic: NdFeB magnet type: Everlasting payment terms: L/C, Western Union, T/T product name: square magnet Certification: RoHsISO9001 size: According to your design Package preview: shape: round model: HJ MAGNET-5 MOQ: 1000 brand: hutchison magnet...... -

Super strong long bar-shaped rare earth neodymium magnet N50 grade

shape: bar, bar Supply capacity: 300000 pieces per week model: Rare earth neodymium N50 grade product name: N50 long bar magnet delivery time: 5-7 days brand: Revitalize Synthetic: Neodymium magnet tolerant: 0.02 MOQ: 10 sample: usable grade: N35-N52, neodymium application: industrial magnet...... -

Super Strong Magnet Neodymium Magnet Permanent Block N35 N52 Rectangular Block Neodymium Ndfeb Rare Earth Magnetic Block

payment terms: L/C, Western Union, T/T tolerant: 0.05mm ~ 0.1mm, ±3% Processing services: Bending, welding, decoiling, cutting, punching, forming MOQ: 1000 product name: square magnet grade: Neodymium magnet Origin: Guangdong, China Processing: accept customization Material: Block Neodymium Magnets.... -

China N52 Ndfeb Strong Disc Block Neodymium Magnet for Sale

payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram, PayPal Supply capacity: 100000000 pieces per month usage: Industrial applications delivery time: 8-14 days Magnetic direction: thickness model: Cylindrical Neodymium Magnets Origin: Guangdong, China product name: Permanent strong...... -

Round Neodymium Magnets

port: Shanghai, Ningbo, any port in China brand: CJ magnet Synthetic: NdFeB magnet Processing services: Bending, welding, decoiling, cutting, punching, forming payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram, paypal, Alipay, cash, etc. application: industrial magnet grade: NdFeB magnet.....