Liquid silicone rubber for concrete statue moulds debuts as a high-performance new product

- $5.89 / >=50 kilograms

- 50 kilograms

- Dongguan Sibetter New Material Technology Co., Ltd.

- Guangdong, China

- Ms Vicky Yin

Product Detail

| hardness: | 40 Shore A | place of origin; place of origin: | Guangdong, China (Mainland), Guangdong, China |

| Packaging Details: | General size packaging: 20kg/barrel, 25kg/barrel, 200kg/barrel | payment terms: | L/C,Western Union,T/T |

| port: | Guangzhou/Shenzhen/Hong Kong | Temperature resistance: | -50-180°C |

| model: | XB-640#,XB-640# | payment terms: | letter of credit, wire transfer |

| Curing time: | 4~6 hours | brand: | Sibetter Silicone, Sibetter Silicone |

| The mixing ratio: | 1:1 | Viscosity: | good for pouring |

| Packaging Preview: | hardener: | platinum cure | |

| Supply capacity: | 3 tons per day |

Liquid silicone rubber for concrete statue moulds debuts as a high-performance new product

Instructions for Liquid Silicone Rubber for High Performance New Concrete Statue Mould

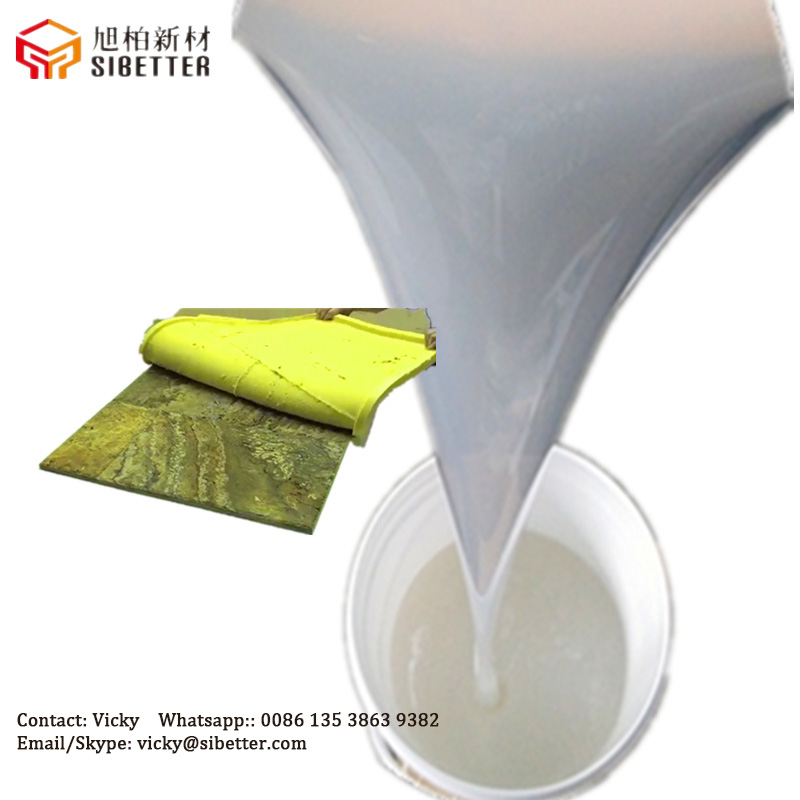

Silicone rubber is generally referred to as two-component silicone rubber, part A and part B. It has excellent flow and good workability.

The mixing ratio is 1:1, which is mainly suitable for mold making applications.

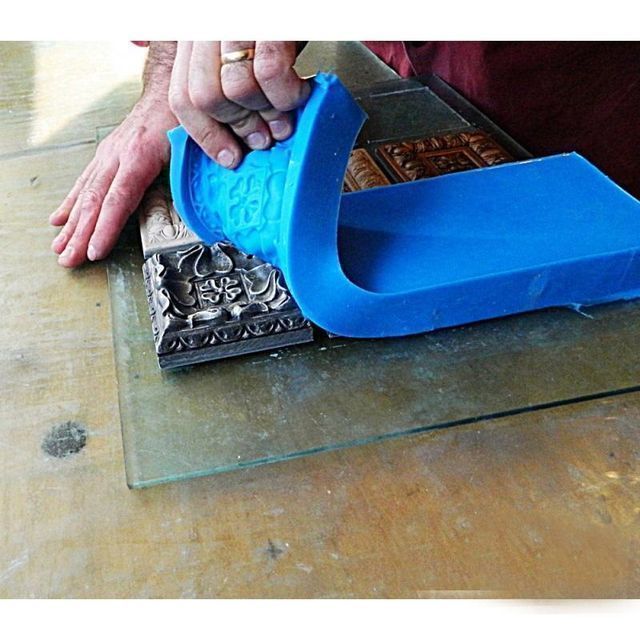

Application of factory-made liquid silicone rubber in the manufacture of concrete statue moulds

Suitable for casting hundreds of products such as:

Shoe mold, tire mold, jewelry mold and other industries.

Gypsum, plaster, concrete, art stone, marble, cement, reinforced plastic, glass fiber resin, GRC, GFRC and other architectural decoration.

PVC, plastic, low melting point alloy, wax, toys and other handicrafts.

Resin, candles, soap, relief and other arts.

Polyurethane imitation wood, resin, polyester, polyurethane, polyurethane and other furniture.

Cement, plaster, bronze, clay, clay, pottery, terracotta, ice, ceramics, statues, figurines and other sculptures.

Advantages of Factory Made Liquid Silicone Rubber for Concrete Statue Moulds

- Low shrinkage (less than 0.1%)

- High tensile and tear strength, high copy time

-Easy to handle (1:1 mixing ratio)

- Good flow and easy pouring operation (about 10000 cps)

- It is food grade

data sheetFactory made liquid silicone rubber for concrete statue mould making

| model· | XB-640 | XB-650 | XB-660 |

| Mixing ratio (weight) | 1:1 | 1:1 | 1:1 |

| Exterior color | translucent | translucent | translucent |

| Hardness (Shore A) | 40±2 | 50±2 | 60±2 |

| Mixing viscosity (mPa s) | 6000±500 | 800±5000 | 10000±500 |

| Working time (at 23℃/75℉, MINS) | 30~40 | 30~40 | 30~40 |

| Cure Time(at 23℃/75℉, HRS) | 3~5 | 3~5 | 3~5 |

| Tensile strength, Mpa | ≥5.8 | ≥6.0 | ≥4.8 |

| Tear strength, kN/m | ≥19.8 | ≥13.6 | ≥12.8 |

| Shrinkage,% | <0.1 | <0.1 | <0.1 |

| Elongation at break, % | ≥300 | ≥250 | ≥100 |

operating instructionsFactory made liquid silicone rubber for concrete statue moulds

1. Please completely remove the model and tools before operation to prevent curing inhibition.

2. Weigh the two parts correctly by electronic scale in two separate containers.

3. Mix the two parts at a 1:1 ratio, and stir parts A and B evenly within 2-3 minutes.

4. Take the mixture around 2-3 and vacuumize to remove air bubbles

minute. (If you don't have a vacuum, pour the mixture carefully and slowly

down one side of the mold frame to make less air bubbles)

5. Enclose the product (original model) with four plastic or wooden boards.

6. Clean your product and brush a layer of release agent (detergent or soapy water) on it

your product.

7. Pour the evacuated mixture from the sides of the mold base into the mold base.

We have our own laboratory with experienced professional R&D and production teams and advanced equipment. Only a part of the entire test is shown here.

Sibet service

1. Pre-sales service:

Sibetter can be your good advisor and assistant; making you great returns in production. We will gather all the details to provide you with the most suitable product for your needs, preparing you a quality product.

2. After-sales service:

Provide considerate service to reduce your worries.

(1) If you don't know how to make molds or products, you will get specific instructions for use

(2) If you have any questions, reply within 24 hours

(3) You are welcome to discuss the use, market and raw materials of silicone rubber with us at any time

(4) If you are a dealer, will send the application and the way to get customers

If you need more information on liquid silicone rubber, please feel free to contact Vicky:

Website: www.sibetter.com

type:wiki(at)sibetter(dot)com

Whatsapp/WeChat: +86-135 3863 9382

Tel: +86-0769-23077651

Fax: +86-0769-23077651

Email: vicky(at)sibetter(dot)com

Related Products

-

Safe skin environmentally friendly soft liquid silicone rubber platinum curing silicone rubber for toy body mold making

Chemical Name: Room temperature vulcanized silicone Keywords: Human skin silicone hardness: 20~30 Shore hardness Packaging Details: There are various packaging sizes: 250g, 500g, 1kg, 3kg, 5kg, 10KG, 20kg, 25kg, 200kg; we can also customize the packaging according to your needs. Package Preview:...... -

Factory direct sales Molde Hacer silicone silicone mold making liquid silicone

thing: JYR-577 HS Code: 39100000 hardness: 0-50 Shore Payment Terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram Supply Ability: 20,000 kg per week Packaging Details: Silicone mold; standard sample packaging is 1kgs, 5kgs, 10kgs, production standard packaging is 20kgs, 25kgs, 200kgs Minimum Order..... -

Liquid mold silicone rubber chocolate mold making bakery product raw material high temperature resistance

brand: Red Union Silicone Supply capacity: 200 tons per month Package: 25kg/barrel Packaging Details: Regular packaging sizes are 1 kg, 10 kg, 50 kg, 200 kg per barrel, OEM/ODM is also welcome payment terms: L/C, Western Union, T/T, MoneyGram, PayPal Shore hardness A: 18A°(±2) port: Shenzhen or...... -

Factory direct selling silicone molding rubber transparent RTV silicone rubber liquid platinum vulcanized silicone rubber

appearance: transparent silicone rubber Origin: Guangdong, China port: Guangzhou, Shenzhen usage: silicone mold Name: Silicone Rubber brand: Jingyi model: JYS-E100, JYS-E100S, JYS-E105, JYS-E110 Material: 100% silicone payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram, PayPal feature:...... -

2023 Platinum Liquid Lifesaving Silicone Food Grade RTV Addition Cured Silicone Rubber For Addition Silicone Making Dildo

usage: mold silicone rubber Origin: Guangdong, China Packaging Details: 2KG/iron drum. color: transparency payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram, Paypal, Cash model: JYS-E100;JYS-E105;JYS-E110 product name: Epoxy Silicone Mold Packaging Details: 20KG/iron drum (silicone chest..... -

101 methyl silicone rubber high-purity factory direct sales of global liquid silicon wholesale raw materials

appearance: Colorless, transparent, no foreign matter. Origin: Anhui, China Packaging Details: It can be transported by general means of transportation. The product should be protected from rain and sun, away from fire and heat sources, not in contact with air, and avoid contact with strong acid,...... -

Cast concrete stone veneer molds for stone bricks and pavers

Supply capacity: 10000pcs cast concrete stone veneer molds for stone bricks and pavers per month weight: 7.0kg/piece Packaging Details: These cast concrete stone veneer molds for stone bricks and pavers are packed in 60*60*30cm carton or wooden case. Can also be customized. life: 3000 times raw...... -

Factory direct sale Ordinary extruded silicone rubber Good physical and mechanical properties Accept OEM/ODM

model: NE2-72 Package preview: brand: DJ Silicone appearance: Milky white, light yellow, no obvious foreign matter. payment terms: L/C, Western Union, T/T, MoneyGram, Moneybooker Origin: Anhui, China Packaging Details: Can be transported by general means of transportation. The product should be...... -

Silicone Liquid Rubber Platinum cured liquid silicone with low viscosity and good tear strength for making dildos

Package preview: model: GT-7040 hardness: 40 Shore A Curing time: 24 hours Supply capacity: 600 tons of mold silicone rubber per month Packaging Details: 1kg/5kg/20kg/25kg/50kg Viscosity: 6000-8000 operating hours: 30-40 minutes Silicone 4: Translucent Silicone Silicone 3: Room temperature TV...... -

High quality cut stone decorative wall cladding

Origin: Henan, China product name: wall stone panel payment terms: L/C, D/A, D/P, T/T, Western Union, MoneyGram brand: Kejie quality: soft, flexible, durable casting: 1200 times weight: Subject to the actual product Supply capacity: 5000 pieces per week feature: natural stone imitation, natural......