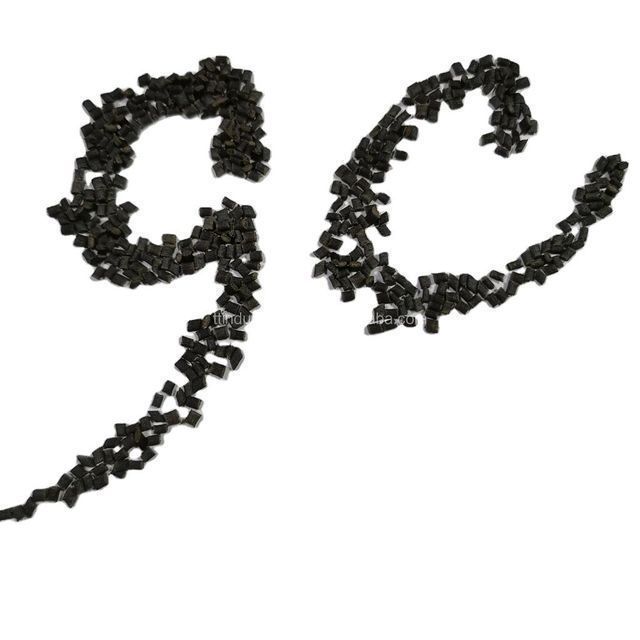

Low price PPS pellet mixing resin

-

$3.75 / 3000 - 4999 kilograms

$3.65 / >=5000 kilograms - 3000 kilograms

- T&T Industry (Shenzhen) Co., Ltd.

- Guangdong, China

- Mr John Chou

Product Detail

| Material: | PPS particles | Flammable: | V1.V0 |

| model: | Z010X | Supply capacity: | 150 metric tons per month |

| place of origin; place of origin: | Guangdong, China | Package preview: | |

| port: | Shenzhen | brand: | GC |

| Certificate: | ISO9001:2008.REACH.ROHS | glass fiber: | 5%-60% |

| pack: | 25Kg/bag | payment terms: | L/C, T/T, PayPal |

| shape: | Granules | Filling content: | Fiberglass, Mineral Fiberglass |

| Packaging Details: | 25kg/bag, international standard packaging | color: | custom made |

Product Description

PPS, also known as: polyphenylene sulfide is a crystalline (crystallinity 55%-65%) high-rigidity white powder polymer with high heat resistance (continuous use temperature can reach 240 ° C), mechanical strength, Rigidity, flammability, electrical properties, dimensional stability are excellent resins, wear resistance, creep resistance, flame retardancy.

Self-extinguishing, up to FR V-0.

High temperature and high humidity still maintain good electrical performance.

Good fluidity, easy molding, almost no shrinkage cavity pits during molding.

It has good affinity with various inorganic fillers.

It was developed to bridge the difference between standard thermoplastic materials (eg PA, POM, PET) and advanced engineering plastics.

feature:

The maximum allowable working temperature is very high in the air, can work continuously at 240°C, and can reach 260°C for a short time), maintain high mechanical strength, stiffness and hardness in high temperature environments, excellent corrosion resistance and hydrolysis resistance (can be found Polyphenylene sulfide (PPS) solvent below 200, dissolves strong inorganic acids, alkalis and salts), excellent wear resistance and friction, very good dimensional stability, excellent resistance to high-energy radiation, good UV resistance , Self-flammability, excellent electrical insulation.

(1) General properties: PPS is a hard and brittle polymer with white appearance and high crystallinity. The relative density of pure PPS is 1.3, but it will increase after modification. The water absorption of PPS is very small, generally only about 0.03%.

(2) Mechanical properties: The mechanical properties of pure PPS are not high, especially the impact strength is low. After reinforced with glass fiber, the impact strength is greatly improved, from 27J/m to 76J/m, increased by 3 times; the tensile strength increased from 6Mpa to 137Mpa, doubled. PPS is very hard, which is rare in engineering plastics. The flexural modulus of pure PPS can reach 3.8Gpa, and it can reach 12.6Gpa after modification by inorganic filling, which is increased by 5 times. The PPO known for its rigidity is only 2.55Gpa, while the PC is only 2.1Gpa.

PPS has good creep resistance and high hardness under load. High wear resistance, the wear resistance at 1000 rpm is only 0.04g, which is further improved after filling F4 and molybdenum disulfide.

PPS also has a certain self-lubricating property. The mechanical properties of PPS are less sensitive to temperature.

(3) Thermal properties: PPS has excellent thermal properties, can withstand 260°C for a short time, and can be used at 200~240°C for a long time; its heat resistance is equivalent to that of PI, second only to F4 plastics, and it is rarely used in thermosetting plastics See.

(4) Electrical performance: The electrical performance of PPS is very outstanding. Compared with other engineering plastics, its dielectric constant and dielectric loss tangent are relatively low, and it changes little in a large frequency, temperature and temperature range. ; PPS has good arc resistance, comparable to thermosetting plastics. PPS is often used in electrical insulation materials, and its dosage can account for about 30%.

(5) Chemical resistance: One of the biggest features of PPS is its good chemical corrosion resistance, and its chemical stability is second only to F4; PPS is resistant to most acids, esters, ketones, aldehydes, phenols and aliphatic hydrocarbons, aromatics, chlorinated Hydrocarbons etc. Not resistant to chlorinated biphenyls and oxidizing acids, oxidizing agents, concentrated sulfuric acid, concentrated nitric acid, radish water, hydrogen peroxide and sodium hypochlorite. PPS has good radiation resistance.

(6) PPS has good flame retardancy, and its oxygen index is above 44%. Compared with other plastics, it is a highly flame-retardant material in plastics (pure PVC oxygen index is 47%, PSF is 30%, PA66 is 29%, 28% for MPPO and 25% for PC).

Specification

type | Specification | describe |

Enhanced PPS | Z40. Z70 | High temperature resistance; high rigidity; good dimensional stability |

PPS/PPO alloy | Z0I0G8 | High temperature resistance |

PPS/PA66 Alloy | Z0H66G8 | High temperature resistance, high toughness |

PPS glass fiber reinforced | ZXX | High rigidity, high heat resistance (xx=30, 40, 45, 65, 70, etc.) |

PPS glass fiber reinforced | Z0-WR | High rigidity, wear resistance |

PPS glass fiber mineral filled | ZXX | High temperature resistance; high rigidity; dimensional stability; high oil resistance and corrosion resistance (xx=30, 40, 45, 65, 70, etc. |

PPS superior toughness | Z40SL | good impact resistance |

PPS true color

Polyphenylene sulfide GF40

PPS mineral glass fiber.

PPS GF40 natural color

PPS R70 (PPS glass fiber and mineral reinforcement)

PPS/PPO alloy

PPS original powder type (for compounding)

PPS/PTFE+carbon fiber

PPS/PA66 Alloy

application

application:

Electronics and electrical appliances: packaging of miniature electronic components, coil bobbins, motor casings, relays, trimming capacitors, etc.

part.

Precision instruments: computers, timers, copiers, temperature sensors and the casings and

Element.

Machinery: pump casings, pump wheels, valves, fans, flow meter parts, flanges, universal heads.

Automotive: clutches, transmissions, gearboxes, bearing brackets, exhaust system parts.

Electronics and electrical appliances: packaging of miniature electronic components, coil bobbins, motor casings, relays, trimming capacitors, etc.

part.

Precision instruments: computers, timers, copiers, temperature sensors and the casings and

Element.

Machinery: pump casings, pump wheels, valves, fans, flow meter parts, flanges, universal heads.

Automotive: clutches, transmissions, gearboxes, bearing brackets, exhaust system parts.

VIEW MORE

Related Products

-

High rigidity PPS GF70 modified PPS particles

Keyuan 40% glass fiber reinforced pump impeller injected with PPS resin Customer opinion Stock pictures Material description Xiamen Keyuan Plastic Co., Ltd. PPS GF40 Natural is a 40% glass fiber reinforced material that combines very high mechanical properties with strength and stiffness, as well...... -

High surface gloss L9560 PPS, 50% mineral reinforced virgin PPS pellets for injection molding

sample: Available Flammable: UL94 V0 Product Name: PPS plastic granules color: Customized colors pack: 25kg/bag application: LED lamp holders, electronic and electrical components, home appliance components Origin: Guangdong, China Payment Terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram...... -

High temperature resistant 40% GF glass fiber PPS plastic granules, suitable for panels

Certificate: TUV Rheinland pack: 25 kg per bag Material: PPS particles Non-flammable: Polystyrene V0 V1 V2 grade: Injection molding grade, extrusion grade, blow molding grade, injection molding grade feature: Aging resistance, enhanced grade, toughened grade, standard grade, high strength, high...... -

PPS granules with reinforced carbon fiber CF30% raw material PPS

Filler content: (5%-50%)gf application: Injection molding, extrusion molding, etc., electronic and electrical components, auto parts, general grade, power tool accessories, sports equipment, food grade, medical grade, home appliance parts Resin: Polyphenylene sulfide pps Place of origin: Fujian...... -

Carbon fiber pps plastic raw material particles Solvay PPS resin Ridon PPS R-7-02 polyphenylene sulfide

pack: 25kg/bag model: R-7-02 Place of origin: USA color: natural/black brand: Solvay Certificate: COA/MSDS/TDS model: R-7-02 brand: Solvay Material name: Polyphenylene sulfide Supply capacity: 200 tons per day Packaging details: 25kg/bag. 1 ton/pallet port: Shanghai payment terms: wire transfer...... -

PPS CF40 manufacturer of polyphenylene sulfide reinforced plastic raw material cf40 PPS

Packaging details: 25kg/bag standard packaging: inner layer (plastic film), outer layer: (paper bag or woven bag). Or we can make it according to customers' requirements. Certificate: ISO9001:2015.SGS.ROHS.REACH.SGS.IATF 16949:2016 color: custom made port: Shenzhen Package preview: pack: 25 kg/bag,.... -

Buy Resin Granules For Sale Factory, Polyphenylene Sulfide Pps Granules

sample: freely color: custom color model: GF30, GF40, CF30, CF40, etc. brand: Hongxu Material: Polyphenylene sulfide port: Tianjin/Ningbo Port payment terms: wire transfer MOQ: 1000 kg Package: 25kg/bag +/-0.2kg Packaging Details: 25kg/bag product name: PPS Plastic Granules Certificate:...... -

PPS 65GF/MD Ryton R7 special engineering plastic polyphenylene sulfide resin

brand: Unicoplus Main features: Good strength, high rigidity, chemical corrosion resistance quality level: Prime Minister, Virgin Supply capacity: 100000 kg per day model: USP90GM65 Flammable: V0 Certification: ISO 9001, ISO 14001, IATF16949, REACH, ROHS Origin: Guangdong, China payment terms: L/C,.... -

Chinese factory for sale! Automobile hot selling engineering plastic PPS reinforced / PPS+40%GF

Origin: Guangdong, China Flammable: V1.V0 Certificate: ISO9001:2008.SGS.ROHS color: Black application: electronic product type: Plastic ResinPPS appearance: particles Delivery Details: 15 working days after payment received payment terms: L/C, T/T brand: GC Packaging Details: 25kg/bag,...... -

Thermally conductive PPS resin price pps pps resin Polyone SFC-5000 TC

model: SFC-5000TC payment terms: L/C, T/T port: Shanghai or Ningbo grade: virgin Package preview: Supply capacity: 31000 tons/year application: Protective coating, curling irons, hair dryers, curling irons, microwave ovens brand: PolyOne color: yellow non-flammable: V0/V2 Origin: Japan Certificate:....