High Quality Injection Molding Service Neway Custom ABS Plastic Parts Supplier Plastic Injection Parts

- $0.01 / >=10 pieces

- 10 pieces

- Dezhou Neway Rubber & Plastic Co., Ltd.

- Shandong, China

- Ms Lisa Ling

Product Detail

| Drawing format: | steps, dwg, igs, pdf | Shaping mode: | injection mold |

| Processing services: | forming | size: | According to customer drawings |

| design service: | According to customer requirements | surface: | smooth, glossy, textured, matte |

| port: | Tianjin/Qingdao | Mold material: | S45C, S50C, P20, 718H, etc. |

| Packaging Details: | Inner plastic bags, outer cartons, and finally pallets, all according to customer requirements. | Material: | ABS+PC, PP, PC, ABS, PA, HIPS, PVC, PE, PS, POM, acrylic, PMMA |

| payment terms: | L/C, D/P, T/T | Package preview: | |

| brand: | neway | pack: | Carton |

| place of origin; place of origin: | Shandong China | Serve: | Custom OEM |

| color: | According to customer requirements | model: | 001 |

| Plastic model type: | injection |

Product Description

newayHigh Quality Injection Mold Molding Service ABS Plastic Custom Parts Supplier, Plastic Injection Parts

Our services include: analysis and improvement of plastic parts

mechanical design, electronic design

Moldflow and Mold Design

Prototype mold

Injection Mold Making

Plastic molding production

painting, printing, assembly

Our advantage

1. Self-owned factory, certified by ISO 9001.

2. Manufacturing molds in-house, 80% of our business is exported.

3. The management is a technical person who always attaches importance to quality and technology development.

4. We have excellent advantages in multi-cavity molds and two-shot molds (with tightening system) and insert molding with precision control process, and know how to achieve CPK≥1.67.

5. Stable employees, we have many excellent employees and technicians who have worked in Neway for more than 5 years.

6. Our engineers and project managers have rich experience and good English communication skills.

Construction lead time: 15-30

Days to get a quote: 24H

Mold precision: ±0.01mm

Mold life: 50-500K shots

Specification

♦ What are the details of our products?

Product Description | ODM injection molding |

plastic material: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,...etc. |

standard: | ISO9001:2008 |

other materials: | Rubber, Slilconce Rubber, LSR, Aluminum, Zinc, Copper...Metal...etc. |

quality: | RoSH and SGS standards |

feature: | Trace and Glitter Free |

size: | According to your 2D, 3D drawings |

Color, quantity, unit price, mold cost, mold size: | to discuss |

pack: | Standard export wooden box packaging, fumigation treatment (on request) |

export country: | Europe, Japan, USA, Australia, UK, Canada, France, Germany, Italy...etc: |

experience: | 20 years of experience in injection mold manufacturing and plastic product production. |

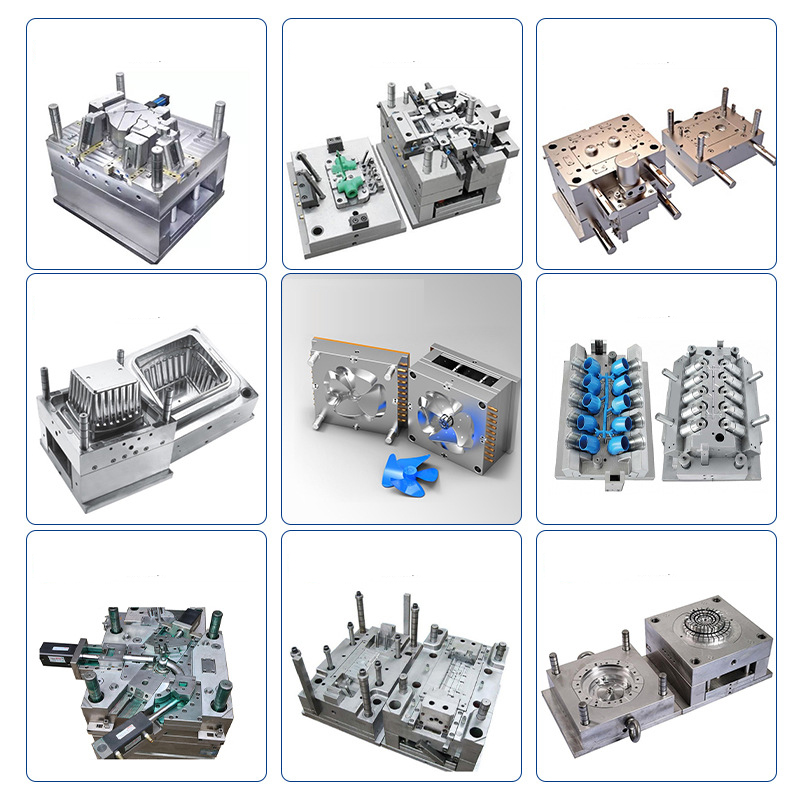

to discuss | In-mold decoration, injection mold, plastic mold, overmold, 2K mold, die casting mold, thermoset mold, stack mold, Interchangeable molds, collapsible mandrels, mold sets, compression molds, cold runner system LSR molds, etc. |

Formwork: | Huayu standard, European standard, world standard |

Mold bottom material: | LKM, FUTA, HASCO, DME,...etc or according to customer's requirement. |

Surface treatment: | Textured (MT Standard), High Gloss Polished |

Cavity/core steel: | P20, 2311, H718, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767...etc. |

hot/cold runner | HUSKY, INCOE, YDDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brands...etc. |

Mold life: | 5,000 to 1,000,000 shots. (Depending on your work environment.) |

Design and programming software: | CAD, CAM, CAE, Pro-E, UG, Soild works, Mold flow, CATIA...etc. |

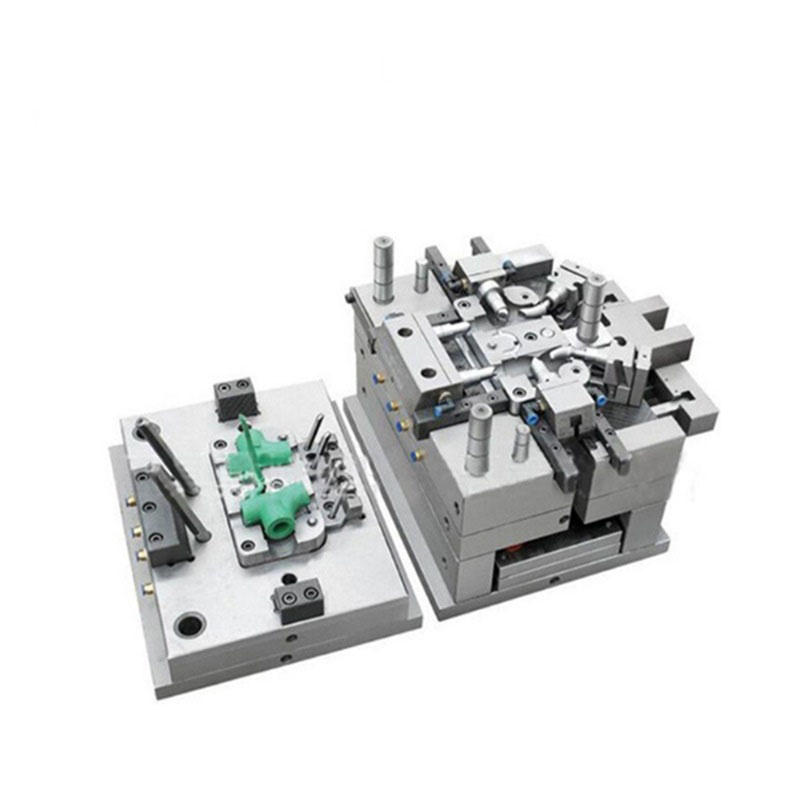

equipment: | High-speed CNC, standard CNC, EDM, wire cutting, WEDM, grinding machine, injection molding machine for 50-3000T trial mold usable. |

We will provide you with a dedicated project engineer manager service.

Project managers are responsible for projects from initial discussions with client representatives through to successful project completion. For a customer this means: one item - one contact.

Project engineers are responsible for the technical aspects of each project. He delegates work to different departments and maintains close contact with the project manager. Clients receive weekly updates on project status.

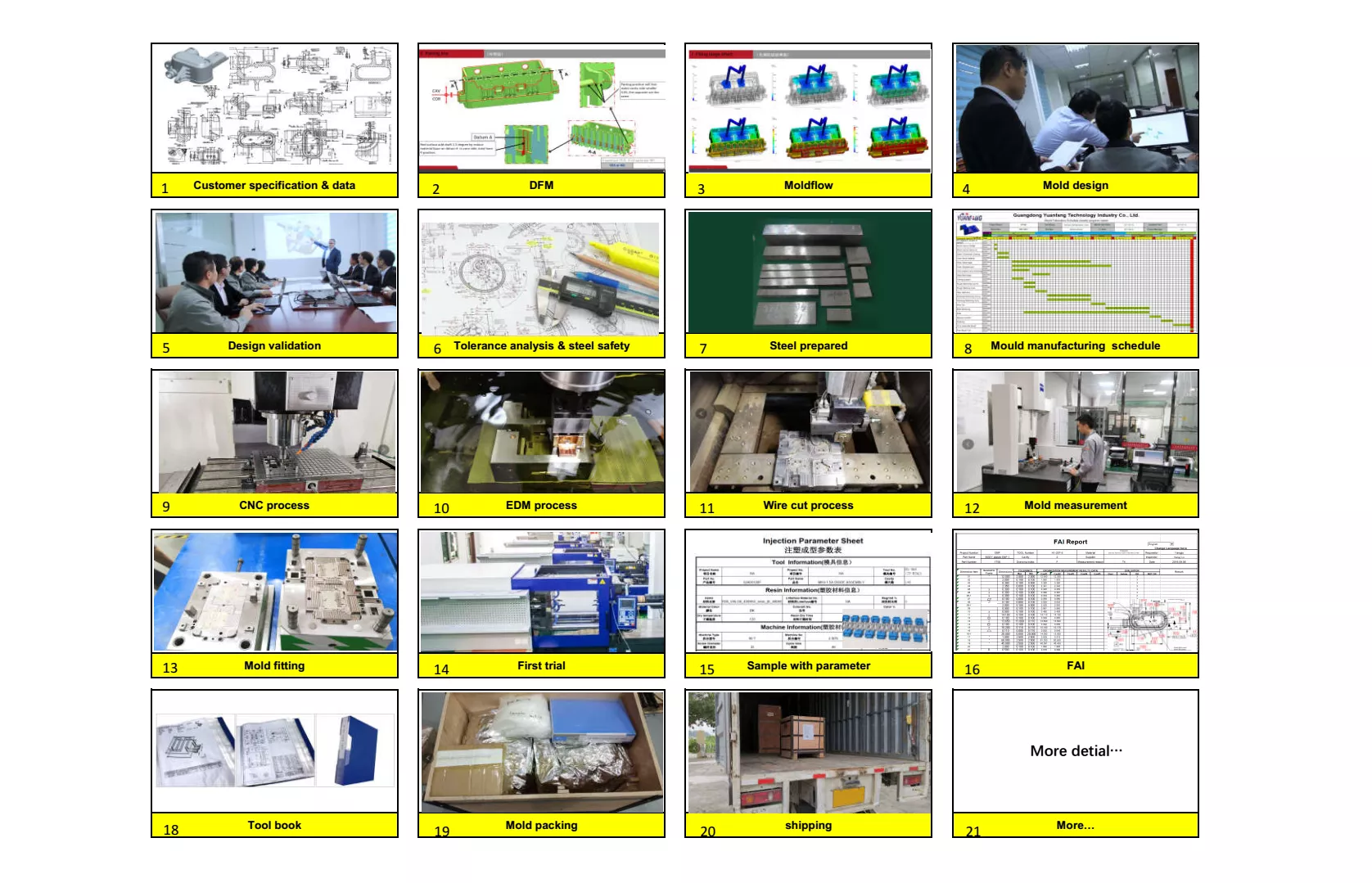

Order Process

RFQ -> Mold Flow -> DFM Analysis -> Mold Design -> Design Verification -> Tolerance Analysis -> Mold Fabrication (Full Size

measurement)->Mold trial(free samples, FAI, CPK)-> 4hours running before mold delivery.

Project managers are responsible for projects from initial discussions with client representatives through to successful project completion. For a customer this means: one item - one contact.

Project engineers are responsible for the technical aspects of each project. He delegates work to different departments and maintains close contact with the project manager. Clients receive weekly updates on project status.

Order Process

RFQ -> Mold Flow -> DFM Analysis -> Mold Design -> Design Verification -> Tolerance Analysis -> Mold Fabrication (Full Size

measurement)->Mold trial(free samples, FAI, CPK)-> 4hours running before mold delivery.

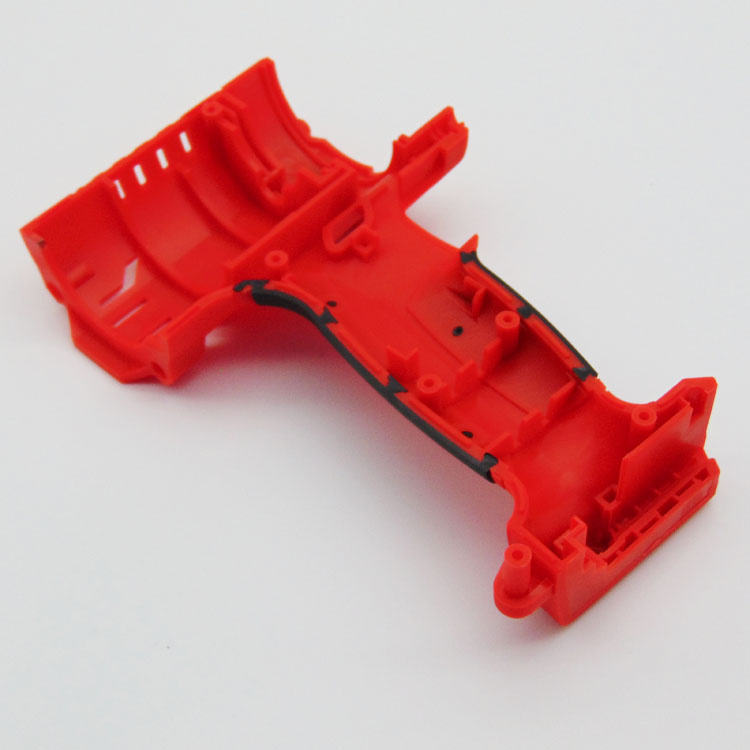

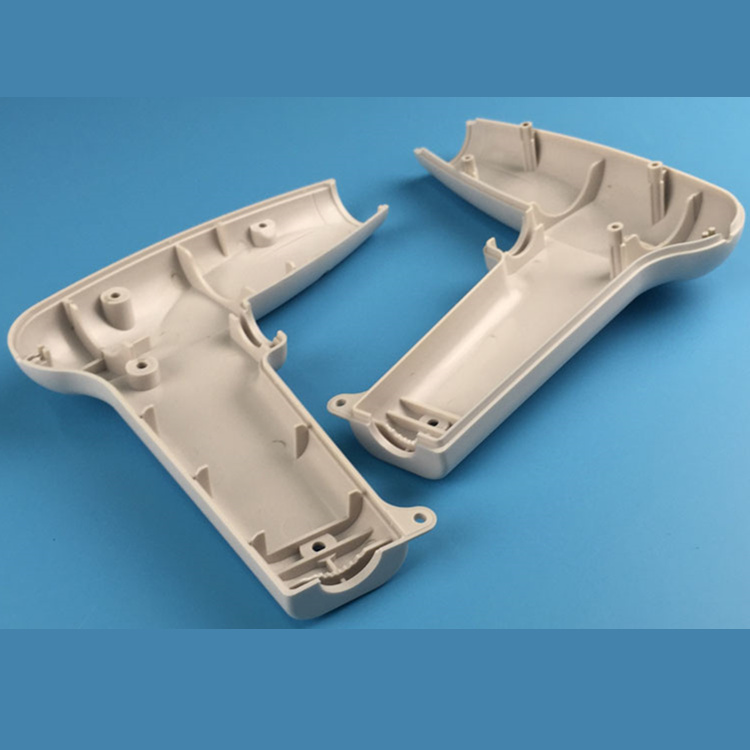

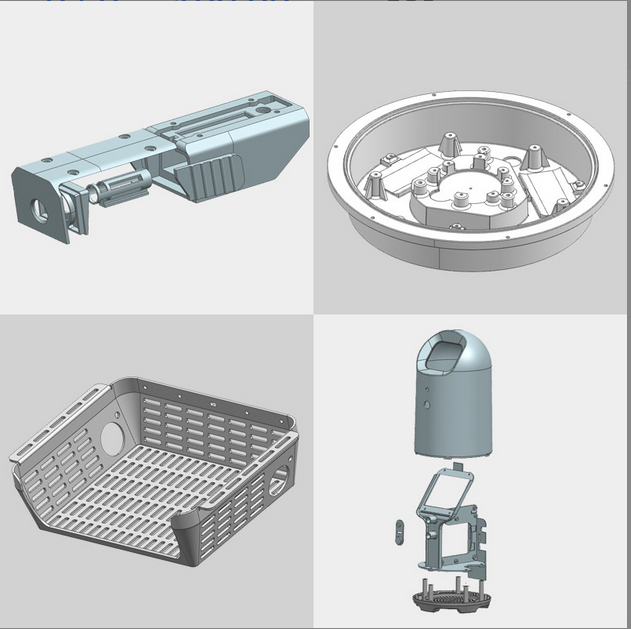

♦CCustomized injection molding product picture display

Injection molding can produce a staggering number of parts per hour. The speed depends on the complexity and size of the mold,

Each cycle time is between 15-120 seconds.

* Low labor cost.

Plastic injection molding is an automated process where most of the process is performed by machines and robots, which

A single operator can control and manage. Automation helps reduce manufacturing costs as overhead increases significantly

reduce.

* Design flexibility.

The mold itself is under extremely high pressure. As a result, the plastic inside the mold

Being more compact, it is possible to imprint a large amount of detail on a part, as well as to print complex or intricate shapes

made.

Thousands of parts can be produced before maintenance tooling is required.

Injection molding is a repeatable process; in other words, the second part you make will be identical to the first

Wait. This is a huge advantage when trying to produce high tolerances and part reliability in high volumes.

Injection molding produces very little post-production waste compared to traditional manufacturing processes. any waste plastic

Usually from sprues and runners. However, any unused or waste plastic can be reground and recycled for future use.

Our advantage

we provide

mold design,Precision plastic mold making,Custom top quality plastic injection molding, assembly work, pad printing,screen printing, paint, ultrasonic weldingandPackaging service.

product design

We provide product design services according to customers' requirements.

We provide product design services according to customers' requirements.

mold design

We will communicate with customers during the mold design process

We will communicate with customers during the mold design process

mold making

Start manufacturing and we will send photos to show the machining process.

Start manufacturing and we will send photos to show the machining process.

provide sample

Once the sample is finished, we will send the sample to customer for confirmation

Once the sample is finished, we will send the sample to customer for confirmation

mass production

After customers confirm the samples, we will start mass production of plastic products.

After customers confirm the samples, we will start mass production of plastic products.

assembly

We also provide assembly services to our customers.

We also provide assembly services to our customers.

painting paint

We can provide coating and rubber coating services to your customers.

We can provide coating and rubber coating services to your customers.

print

We also provide silk printing, pad printing, heat transfer printing services.

We also provide silk printing, pad printing, heat transfer printing services.

packing box

We also make packaging boxes according to customer requirements.

We also make packaging boxes according to customer requirements.

VIEW MORE

Related Products

-

Multifunctional children's plastic assembled cloth toy drawer storage cabinet

Product Description Multifunctional children's plastic assembled cloth toy drawer storage cabinet Product details Origin Chinese mainland) model SOC001-C Plastic type polypropylene type storage drawers Material plastic use Bedding, clothing, sundries, tools Applicable space Wardrobe Package 1...... -

2mm, 3mm, 4mm, 5mm, 6mm, 7mm nylon pom pe support rod/3mm nylon rod/nylon strip

Package preview: port: Tianjin/Qingdao payment terms: L/C, D/P, wire transfer type: extrusion raw material: PP, PE, PVC, PETG, PC, PET, PBT, TPE, TPU, ABS, PA, etc. brand: XW-001 size: custom made model: XW-001,XW-001 thickness: custom made Plastic molding type: extrusion Place of origin: Shandong..... -

OEM/ODM Speaker/Pro Audio Consumer Electronics Plastic Enclosure/Box/Enclosure Prototype

design service: accepted ID: custom logo Plastic molding type: injection product name: Speaker enclosure Supply capacity: 300000 pieces per month capacity: 100ml Serve: OEM\ODM model: Da-5335 Injection mold life: 500,000 shots sample: available brand: Delta Asia Plot format:...... -

20mm Male Valve Pepper Spray Actuator with Keychain

payment terms: L/C, T/T type: 1-13 Origin: China Shanghai Supply capacity: 100,000,000 pieces per year model: 0006 brand: Processing 20mm male valve pepper spray actuator with card chain product name Compressed Gas Pepper Spray Actuator Material plastic use aerosol usage pepper spray sample free...... -

HIGH QUALITY PLASTIC CHAIR

Packaging Details: 20PCS/bag Plastic model type: injection brand: Winstar port: Vietnam color: Lavender-Pink-Green-Beige Origin: Bac Giang, Vietnam usage: home furniture Package preview: payment terms: L/C, T/T color: custom made Product Description plastic chair -Material made of plastic- durable-.... -

Plastic mat 6x9 color mat

product name: color pad feature: rich and colorful payment terms: L/C, T/T brand: NA, Mayura Origin: Maharashtra, India port: Mumbai usage: picnic/garden/family/sleep MOQ: 2000 Processing services: to weave color: multiple colour Supply capacity: 52000 pieces per month Packaging Details:...... -

Custom Medical Equipment Plastic Case Plastic Case Mold Manufacturer

model: 001 Package preview: Mold material: S45C, S50C, P20, 718H, etc. Origin: Shandong China size: According to customer drawings brand: neway Plastic model type: injection Material: ABS+PC, PP, PC, ABS, PA, HIPS, PVC, PE, PS, POM, acrylic, PMMA Drawing format: steps, dwg, igs, pdf surface:...... -

Makeup Case 9 Slots Lipstick Display Holder Storage Box

place of origin; place of origin: Zhejiang, China Packaging Details: pp bag + color box + transport carton Processing services: Forming, cutting payment terms: Western Union, T/T Supply capacity: 1000 pieces per day plastic: other Plastic model type: injection port: Ningbo, Shanghai Material:...... -

Lipstick Display Stand Cosmetic Case Jewelry Box

plastic: other product name: makeup box Plastic model type: injection Material: polystyrene payment terms: Western Union, T/T port: Ningbo, Shanghai Packaging Details: pp bag + color box + transport carton place of origin; place of origin: Zhejiang, China Supply capacity: 1000 pieces per day...... -

Professional Custom Molded Plastic Home Appliance Knob Covering

product name: Plastic Plating Appliance Knobs brand: set sail usage: control switch function key Packaging Details: PE bag, carton place of origin; place of origin: Guangdong, China Serve: Custom OEM shape: rectangle color: multicolor Plastic model type: injection Supply capacity: 100000 sets per......