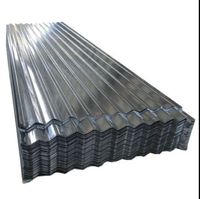

Hot Sale Galvanized Sheet Metal Roofing Corrugated Steel Sheet Roofing Price Zinc Roofing Sheet

- $380.00 / >=5 pieces

- 5 pieces

- Haitu (shandong) Steel Co., Ltd

- Shandong, China

- Ms wendy wang

Product Detail

| product name: | Corrugated Roof Sheet | Surface treatment: | Non-chromate passivation |

| Supply capacity: | 5000 tons/month | place of origin; place of origin: | Shandong China |

| thickness: | 0.12-1.2mm | application: | Roofing, Architecture, Roof Tiles, Ceilings |

| delivery time: | 22-30 days | Special Purpose: | roof structure |

| Packaging Details: | Piece by piece, in bundles, wrapped in external pvc | coating: | Z61-Z90 |

| length: | 1400-1799mm, 1800-2000mm, 2001-3600mm | tolerant: | ±1% |

| brand: | high temperature, high temperature | Processing service: | Welding, punching, cutting, bending, uncoiling |

| width: | 600-1250mm | standard: | SUS, Aisi, ASTM, BS, DIN, GB, JIS |

| model: | 0.12-2.0mm*600-1250mm | hardness: | full hard |

| Sequin Type: | ordinary sequins | payment terms: | letter of credit, wire transfer |

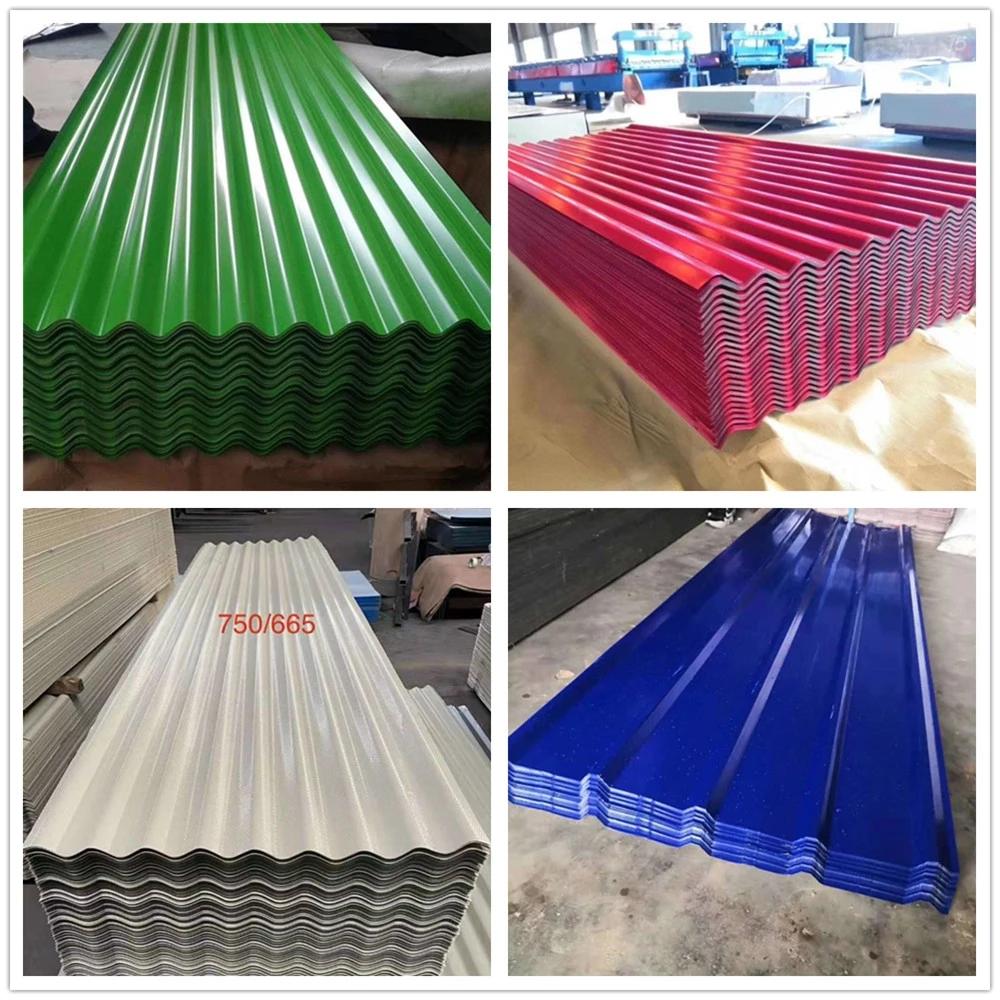

| grade: | DX51D | shape: | waves |

| surface: | coating | Certificate: | ce,BIS,JIS,GS,ISO9001 |

| port: | Qingdao | Packaging Preview: | |

| Key words: | GI Roof Slabs |

Product Description

Cold Rolled CGI Corrugated Galvanized Steel

Corrugated galvanized iron or steel (commonly known as corrugated iron (near universal), creeping tin (taken from British military slang),

Pailing (Caribbean English), corrugated sheet metal (North American) and occasionally abbreviated CGI) is a construction material consisting of hot-dip galvanized mild steel sheets, cold rolled to create a linear corrugated pattern in them. The corrugations increase the bending strength of the sheet in the direction perpendicular to the corrugations, but not parallel to the corrugations. Typically, each sheet is made longer in its strength direction.

Pailing (Caribbean English), corrugated sheet metal (North American) and occasionally abbreviated CGI) is a construction material consisting of hot-dip galvanized mild steel sheets, cold rolled to create a linear corrugated pattern in them. The corrugations increase the bending strength of the sheet in the direction perpendicular to the corrugations, but not parallel to the corrugations. Typically, each sheet is made longer in its strength direction.

CGIs are lightweight and easy to transport. It was and is widely used, especially in rural and military buildings such as sheds and water tanks. Its unique properties have been used in the development of countries such as Australia since the 1840s, and it is still helping developing countries today.

Corrugated iron is equivalent to a tin roof.

Corrugated iron is equivalent to a tin roof.

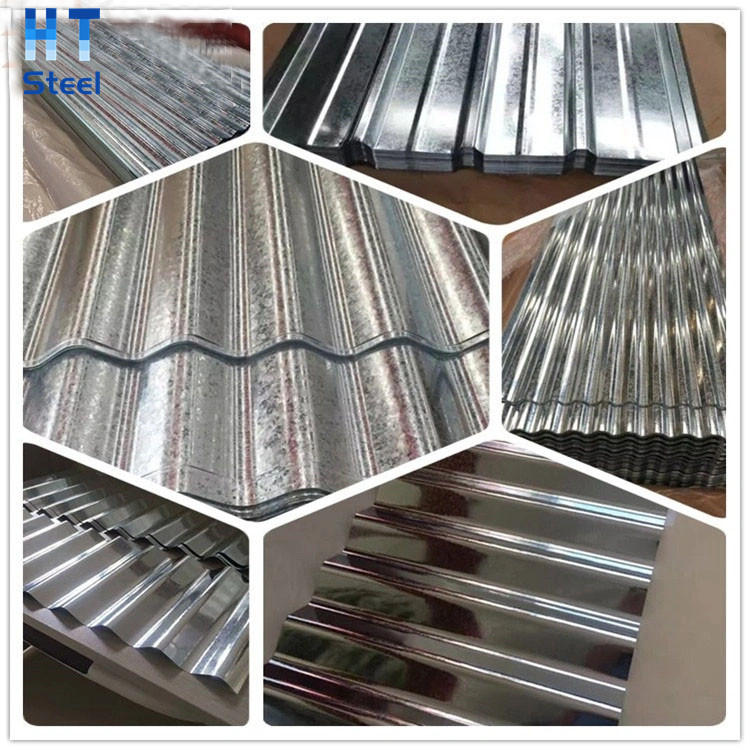

Hot dip galvanizing is a form of galvanizing. This is the process of coating steel with zinc, which alloys with the surface of the base metal when the metal is dipped into a bath of molten zinc at a temperature of about 840°F (449°C).

Galvanized steel is widely used in applications requiring corrosion resistance without the cost of stainless steel and is considered superior in terms of cost and life cycle. It can be identified by the crystalline pattern on the surface.

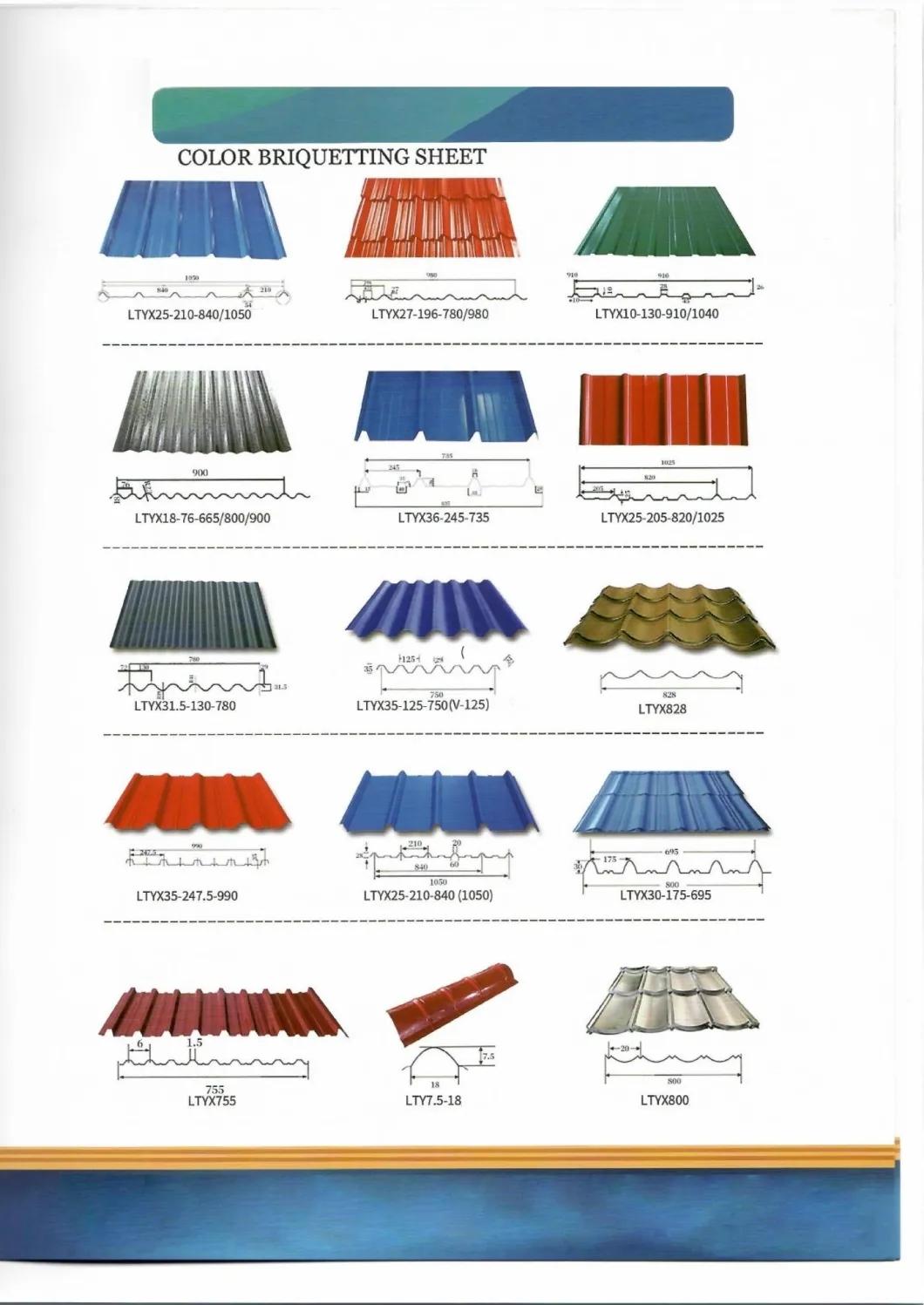

Specification

Corrugated Galvanized Roof Sheet | ||||||

Material | State Grid, SGCH, JIS G3302, DX51D, DX52D, DX53D | |||||

thickness | 0.10 - 1mm or according to customer requirements | |||||

width | 600 - 1250mm or as customer's request | |||||

length | 2 - 5 meters | |||||

tolerant | Thickness: +/- 0.02mm Width: +/-2mm | |||||

Zinc coating | 30 - 275g/m2 | |||||

surface treatment | Oil-free, dry, chromate-passivated, non-chromate-passivated | |||||

Certification | ISO 9001-2008, SGS, CE, BV | |||||

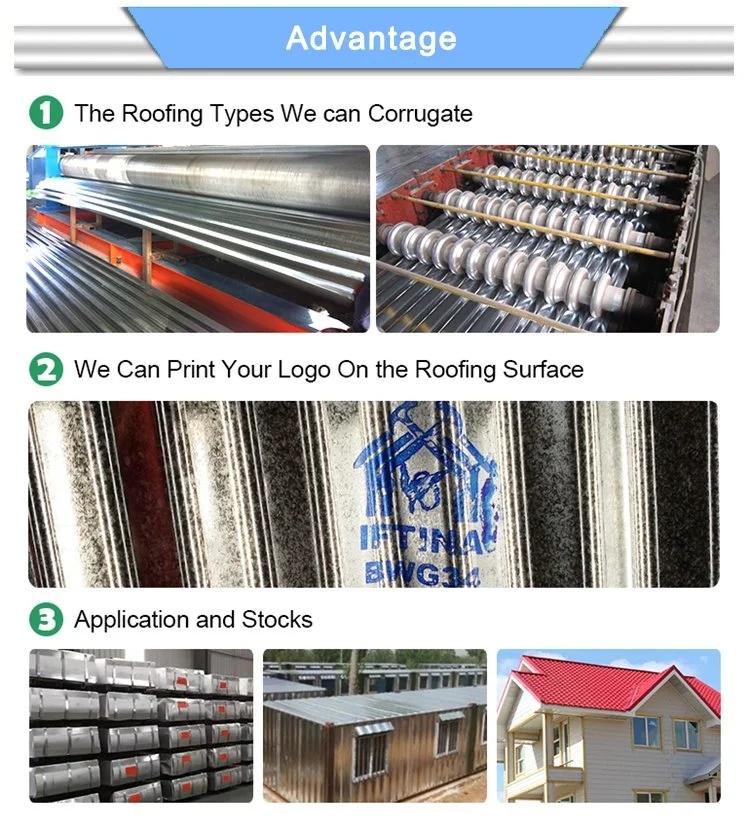

technology | Cold Rolled -> Hot Galvanized -> Color Coated -> Corrugated | |||||

Corrugated depth | From 15mm to 18mm | |||||

asphalt | From 75mm to 78mm | |||||

Gloss | Gloss can be changed according to customer's request. We can also do some high gloss. | |||||

standard | GB/T 12754-2006; ASTM A 755; EN 10169; JIS G 3312; Artificial Intelligence; Bachelor of Science; DIN | |||||

grade | CGCC/SGCC/SGCH/SPCC | |||||

Yield Strength | 550MPA/as needed | |||||

tensile strength | 600MPA/as needed | |||||

hardness | Full hard/soft/on demand | |||||

application | Various roofs or walls of large factories, warehouses, exhibition halls, gymnasiums, etc. | |||||

VIEW MORE

Related Products

-

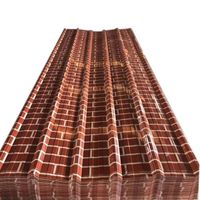

Prepainted Aluminum Roof GI Roof Corrugated Metal Sheet

Certificate: CE, JIS, ISO9001 width: 600mm-1500mm Supply capacity: 40000 tons per month technology: cold rolled Name: Steel Roof Sheets color: Ral color/customer sample color port: Shanghai, Ningbo or as your request payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram shape: custom made...... -

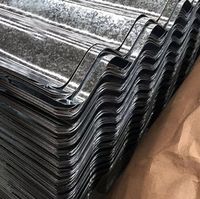

Hot sale roof sheet hot rolled galvanized steel sheet roof corrugated sheet corrugated iron sheet

Key words: Air conditioning pipe Processing services: Welding, punching, cutting, bending, decoiling Packaging Details: standard packaging surface: bright Certificate: ISO9001 thickness: 0.14-0.20MM Package preview: standard: ASTM B280/EN 12735-1, bs EN GB AiSi ASTM DIN JIS color: raul color shape:.... -

Long Span Roof Truss Price Overstock GI Galvanized Galvanized Corrugated Roof Tile Metal Sheet 04mm

surface: Galvanized coating brand: high steel coating: Z10-Z29 Supply capacity: 25000 tons per month Processing services: Welding, punching, cutting, bending, decoiling standard: bs EN GB AiSi ASTM DIN JIS Key words: Galvanized corrugated roof steel sheet product name: Corrugated Galvanized Steel...... -

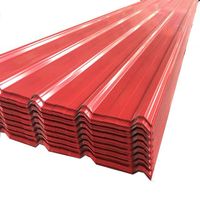

Modern Heavy Duty Painted Zinc Aluminum GI IBR Iron Corrugated Roof Sheet

type: Steel plate, color coated steel plate tolerant: ±1% application: architectural or structural steel standard: JIS coating: Z41-Z60 Supply capacity: 40,000 tons/month surface: Galvanized coating color: Ral color/customer sample color payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram...... -

ASTM 22 Specification High Strength Stone Coated Corrugated Galvalume Hot Dip Galvanized Cold Rolled Roofing Marine Steel Plate

Scope of application: Factory warehouse wall construction and factory renovation coating: Z61-Z90 length: 1400-1799mm, 1800-2000mm, 2001-3600mm, 3601-3660mm proper temperature: -50℃-70℃ Tensile/Bending Strength: 29.4mpa/ 45.6mpa Zinc coating: 30-275 g/m2 port: Qingdao, Shanghai, Tianjin, etc....... -

Cheap Price Standard Size Zinc Galvanized Iron GI Galvalume PPGI PPGL Roof Sheet Corrugated Steel Sheet

Supply capacity: 5000 tons per month Spangle type: zero sequins Package: Standard Airworthy Packaging length: Customer requirements, 1400-1799mm, 1800-2000mm, 2001-3600mm, 3601-3660mm shape: Ripple wave Origin: Shandong China application: Roof panels, wall panels, metal roofing MOQ: 1 ton grade:...... -

China supply custom wholesale corrugated steel roof panel galvanized steel sheet 5mm hot sale

application: put up coating: Z30-Z40 payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram shape: flat Zinc coating: 30-275 g/m2 expiration of pay: 30%TT advance payment + 70% balance Processing services: Welding, punching, cutting, bending, decoiling port: Shanghai Tianjin Material:...... -

High Quality Galvanized Prepainted Corrugated Steel Roofing Metal Sheet Tin Roofing Price Low Slope Roofing

hardness: medium hard payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram product name: corrugated roof sheet delivery time: 8-14 days Spangle type: regular sequins Certificate: ISO 9001:2008/British Virgin Islands brand: Century Tongyuan coating: Z41-Z60 standard: AiSi, ASTM, bs, DIN, GB,..... -

22 Gauge 4x8 Cold Rolled GI Corrugated Zinc Roof Sheet Metal Price Galvanized Steel Roof Sheet

Origin: Shandong China Package preview: thickness: 0.14-0.20MM length: 1400-1799mm, 1800-2000mm, 2001-3600mm, 3601-3660mm technology: Cold Rolled Hot Rolled payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram Applicable slope: 10°-90° Coating Type: (polyvinylidene fluoride, polyvinylidene...... -

Corrugated Sheet Size 26 Galvanized Aluminum 60g Steel Sheet Cold Rolled Steel Sheet 600-12500mm For Ppgl Coil Cold Rolled

Packaging Details: Standard shipping packing according to customer requirements Origin: Jiangsu, China MOQ: 1 ton delivery time: within 15-20 days thickness: 0.12-6mm or as your request Processing services: Welding, punching, cutting, bending, decoiling port: Tianjin, Qingdao Zinc coating: 40-275......