LC TT payment factory price sus430 cold rolled spiral stainless steel coil price per ton

- $99.00 /piece

- 1 piece

- Wuxi liansen Metal Technology Co.,Ltd

- Jiangsu, China

- Ms Josie Kong

Product Detail

| Supply capacity: | 20,000 tons/month | technology: | Cold Rolled Hot Rolled |

| Package preview: | Steel grade: | 301L, 301, 304N, 310S, 410, 204C3, 316Ti, 316L, 316, 410S, 410L, 436L, LH, 430, 304, 204C2, 409L, 436, 304L, 904L, 304J1 | |

| MOQ: | 1 ton | width: | 1000-2000mm, customized size |

| brand: | United Sen | Processing services: | Bending, welding, decoiling, punching, cutting |

| delivery time: | 7-14 days | The main purpose: | Deep drawn parts such as containers and acid pipelines |

| length: | as requested | standard: | JIS, ASTM, DIN, EN, JIS, AISI, ASTM, GB, DIN, EN, etc., JIS/AiSi/ASTM/GB/DIN/EN/bs |

| edge: | Edging and trimming | port: | Shanghai Qingdao |

| Packaging Details: | According to customer requirements | grade: | 200 series/300 series/400 series/500 series/600 series/900 series |

| sample: | free | Surface treatment: | BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

| Certification: | SGS | application: | Deep drawing parts and acid pipeline |

| payment terms: | L/C, T/T | product name: | Color stainless steel coil |

| Types of: | Coil | thickness: | 2-14mm, 0.5-8mm |

| tolerant: | ±1% | model: | 201/301/304/316/410/430/436/904.etc |

| place of origin; place of origin: | Jiangsu, China | surface: | NO.1,2B,NO.4,BA,HL or according to customer requirements |

Product Description

Frequently used numbers | ASTM | Mechanical Specifications | ||||

Rm MPa | YS (MPa) | A5 | ||||

201 | 201 | ≥520 | ≥275 | ≥40 | ||

1Cr17Ni7 | ≥520 | ≥205 | ≥205 | |||

301 | 301 | ≥520 | ≥205 | ≥40 | ||

1Cr18Ni9 | ≥520 | ≥205 | ≥40 | |||

0Cr18Ni9 | ≥520 | ≥205 | ≥40 | |||

304 | 304 | ≥515 | ≥205 | ≥205 | ||

00Cr19Ni10 | ≥480 | ≥175 | ≥40 | |||

304L | 304L | ≥485 | ≥170 | ≥30 | ||

309S | 309S | ≥520 | ≥205 | ≥40 | ||

0Cr25Ni20 | ≥520 | ≥205 | ≥40 | |||

310S | 310S | ≥520 | ≥205 | ≥40 | ||

0Cr17Ni12Mo2 | ≥520 | ≥205 | ≥40 | |||

316 | 316 | ≥515 | ≥205 | ≥30 | ||

00Cr17Ni14Mo2 | ≥480 | ≥175 | ≥40 | |||

316L | 316L | ≥485 | ≥170 | ≥30 | ||

316Ti | 316Ti | ≥515 | ≥205 | ≥30 | ||

0Cr19Ni13Mo3 | ≥520 | ≥205 | ≥40 | |||

00Cr19Ni13Mo3 | ≥480 | ≥177 | ≥40 | |||

317L | 317L | ≥480 | ≥176 | ≥40 | ||

0Cr18Ni10Ti | ≥520 | ≥205 | ≥40 | |||

321 | 321 | ≥515 | ≥205 | ≥30 | ||

409L | ≥360 | ≥175 | ≥25 | |||

410 | 410 | ≥440 | ≥205 | ≥20 | ||

430 | 430 | ≥450 | ≥205 | ≥22 | ||

444 | 444 | ≥480 | ≥310 | ≥30 | ||

410S | ≥420 | ≥290 | ≥33 | |||

2205/S31803/F51 | 2205 | ≥450 | ≥620 | ≥15 | ||

2507/S32750/F53 | 2507 | ≥550 | ≥800 | ≥25 | ||

630 | ≥520 | ≥785 | ≥18 | |||

904L/N08904 | ≥490 | ≥216 | ≥35 | |||

thing | surface treatment | Surface treatment method | ||||

number one | human resources department | Heat treatment after hot rolling, picking, or handling with | ||||

NO.2D | no SPM | Method of heat treatment after cold rolling, surface rolls with wool or final skin calendering | ||||

NO.2B | After SPM | Appropriate cold gloss method for No.2 processed materials | ||||

bachelor | Bright annealing | Bright heat treatment after cold rolling to increase gloss and cold light effect | ||||

NO.3 | Bright, coarse grain processing | NO.2D or NO.2B processing wood NO.150-180 polishing abrasive abrasive belt | ||||

NO.4 | After CPL | NO.2D or NO.2B processing wood No. 150-180 polishing abrasive abrasive belt | ||||

240# | fine line sanding | NO.2D or NO.2B processing wood 240 polishing abrasive abrasive belt | ||||

320# | More than 240 grinding lines | NO.2D or NO.2B processing wood 320 polishing abrasive abrasive belt | ||||

400# | close to BA gloss | MO.2B Wood 400 polishing wheel polishing method | ||||

HL (hairline) | Polishing line with long continuous processing time | Continuous polishing line processing method as long as hair in a belt of suitable size (usually mostly 150-240 grit) | ||||

NO.6 | NO.4 can't deal with reflection and extinction | NO.4 Processing materials for polishing Tampico wire drawing | ||||

NO.7 | High precision mirror processing | No. 600 Rotary Buffing Wheel with Polishing | ||||

NO.8 | Highest reflectivity mirror finish | The particles of the abrasive material are fine, polished sequentially, mirror polished with polishing | ||||

VIEW MORE

Related Products

-

2022 autumn and winter new style small fragrant jacket women's trendy ins second-hand discount women's clothing

Product Description Ropa Wholesale 2021 Fashion Big Bulk Free Kids Advent Assorted Shirts Bundle Clothes Product name women's clothing usage daily use color As shown in the picture size See the table below for specific size information logo Accept customer logo Package Opp bag/carton Minimum order..... -

30MM 2.MM 10MM THICK 304/316 INNOX PLATE.

Place of origin: Shandong Province, China Package: Standard airworthy packaging surface: BA/2B/NO.1//NO.4/8K/HL/2D/1D Processing services: Bending, welding, uncoiling, punching, cutting length: 1500mm-6000mm Steel grade: 301,310S,316L,316,321,430,304,304L port: Tianjin Port, Shanghai Port Surface...... -

Foshan 4X8 Elevator Wall Panel Decoration Panel Sus 201 304L 316 430 Stainless Steel Plate Decoration 8K Rose Gold Mirror Metal

Surface treatment: NO.6k 8k 10k 12k mirror port: Guangzhou, Shenzhen, Foshan model: SSSM tolerant: ±3% width: 1000/1219/1250/1500mm/customized delivery time: 7-25 days, within 7 days color: gold titanium or customized Supply capacity: 30000 tons per month Surface treatment: 2B Processing services:..... -

Factory Color 201 304 316 316L Stamp 1.0mm Thick Stainless Steel Ceiling Decoration Panel

type: Stamped stainless steel plate Processing services: Bending, welding, punching, cutting length: 2000/2438/2500/3000/3048mm grade: 200/300/400 series Surface treatment: 8K/HL/NO.4/BA Packaging Details: Standard shipping package, covered with PE film, then wrapped with waterproof woven paper,...... -

Factory wholesale 201 304 316 430 gold mirror stainless steel plate

delivery time: 15-21 days standard: Aisi color: Various colors are available Product Category: 201 304 mirror stainless steel plate port: Shanghai Suzhou thickness: 0.3-3.0mm Origin: Jia payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram sample: free sample Thickness Tolerance: +/- 0.03 mm.... -

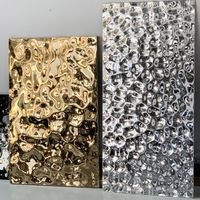

Golden Stainless Steel Sheet Water Ripple Stainless Steel Sheet Wall Decor ASTM JIS Cold Rolled Stainless Steel Sheet

type: plate payment terms: L/C, T/T Surface treatment: No.4, hairline, mirror polishing, etching, embossing, PVD color, etc. port: Foshan/Guangzhou/Shenzhen Material: Stainless steel Packaging Details: Standard export wooden case/frame Color coating: Gold, Rose, Black, Blue, Bronze. any color...... -

China Suppliers Custom Good Embossed Stainless Steel Sheet 304 316 0.5mm 0.6mm 0.7mm 1mm Water Corrugated Stainless Steel Sheet

edge: milling or trimming Steel grade: 301L,S30815,301,304N,310S,S32305,410,204C3,316Ti,316L,441,316,L4,420J1,321,410S,410L,436L,443,LH,L1,S32304,314,347,430,309S,304,439,204C2,425M,409L,420J2 ,436,445,304L,405,370,S32101,904L,444,301LN,305,429,304J1,317L place of origin; place of origin: Jiangsu,..... -

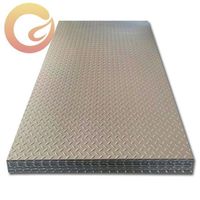

ZHONGRUN 304/201/202/430/410/630/316/316L/304 diamond/grid decorative embossed stainless steel skid plate

width: 600mm-1800mm, 50-3000mm or customized according to your requirements length: 2m-12m or customized according to customer's special requirements delivery time: 0-30 days, 15-21 days after receiving deposit or L/C in our bank surface: Low carbon steel flat, hot-dip galvanized, etc. Packaging...... -

Ceiling ceiling interior decoration flow ripple large wave ripple and other customized stainless steel plates

Processing service: Bending, welding, uncoiling, punching, cutting Surface treatment: 2B, BA, NO.1, NO.4, NO.8, 8K, Mirror, Brushed Supply capacity: 40 pieces per month shape: Customized upon request port: Shenzhen, Guangzhou, Foshan or upon request Pay: letter of credit, wire transfer Steel grade:.... -

China manufacturer sell luxury 304 201 430 8k 2b stainless steel sheet mirror polished stainless steel sheet

Packaging Details: Standard Seaworthy Packaging Packaging Preview: business type: Manufacturing and Trading Company length: custom made thickness: 0.3-3.0mm main market: Middle East, Asia, North America, Europe Steel grade: 316,443,430,304,439 delivery time: 22-30 days brand: Hunder port: Shanghai,....