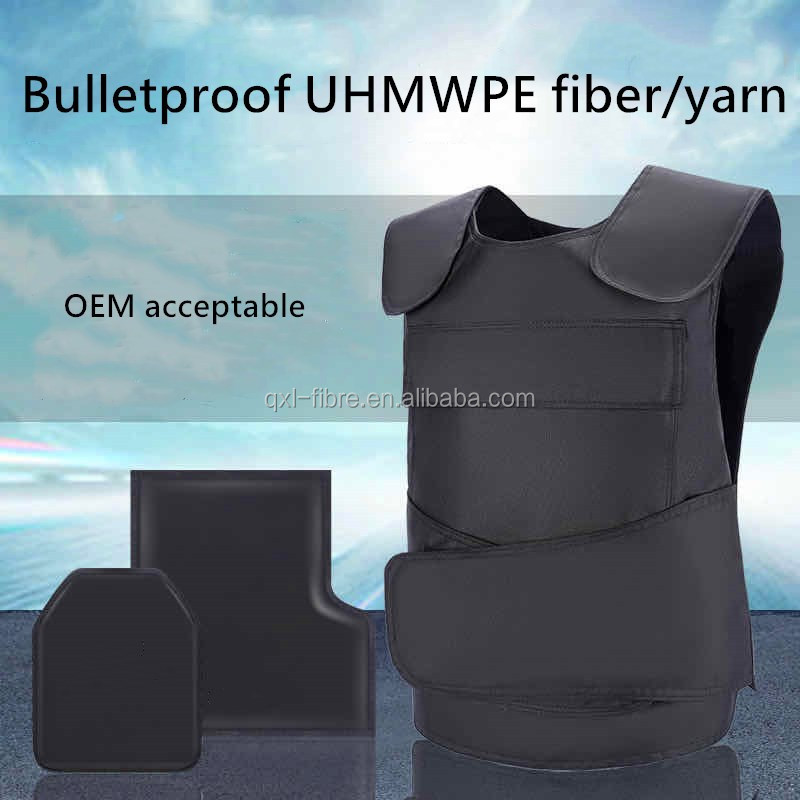

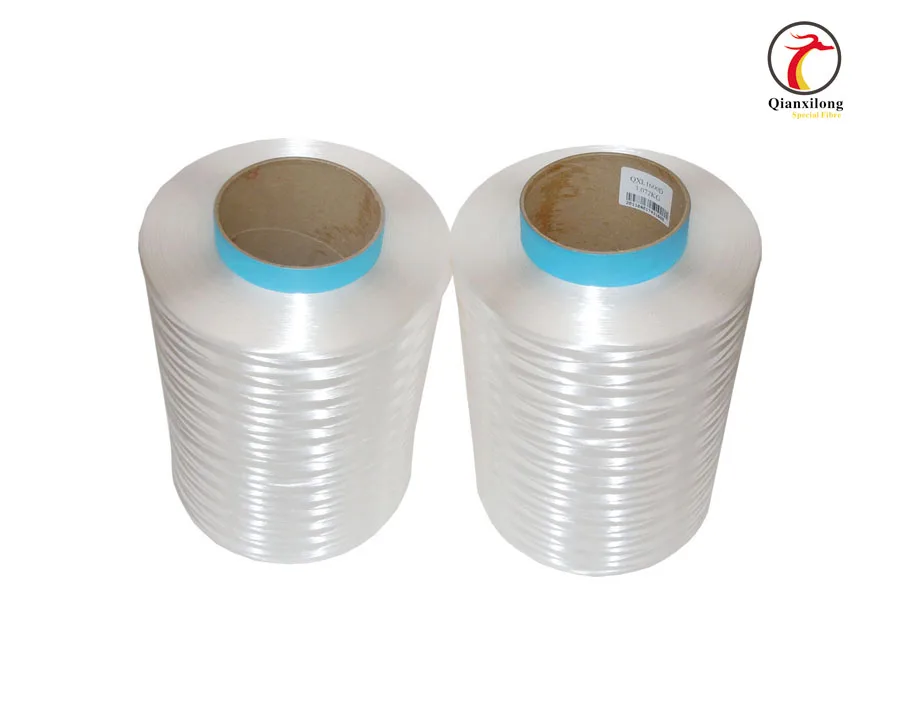

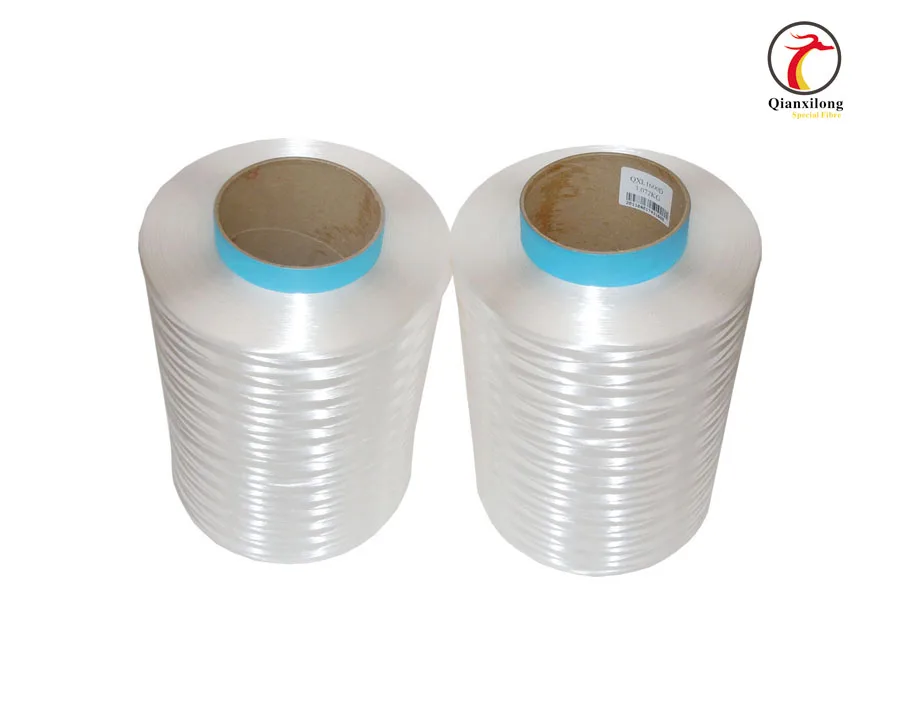

High quality UHMWPE fiber for UD cloth body armor

- $10.00 /kilogram

- 1 kilogram

- Zhejiang Qianxilong Special Fibre Co., Ltd.

- Zhejiang, China

- Ms Cathy Yang

Product Detail

| feature: | Abrasion-resistant, impact-resistant, cut-resistant, UV-resistant, bullet-proof, corrosion-resistant, high strength, light weight, radiation-resistant | Material: | UHMWPE Fiber |

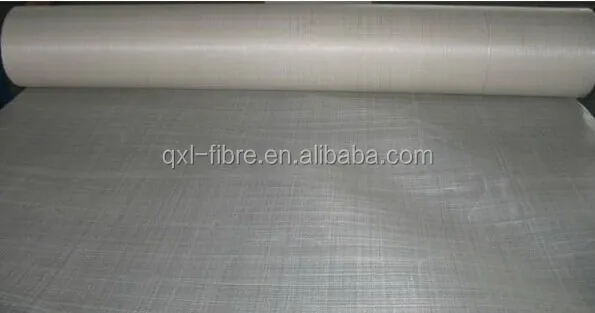

| Package preview: | model: | QXL-1600D | |

| Supply capacity: | 400 metric tons per month | type: | uhmwpe fiber for body armor |

| Origin: | Zhejiang, China | toughness: | 38g/day |

| brand: | Qian Xilong | payment terms: | L/C, D/P, T/T |

| Fineness: | 480F | port: | Shanghai/Ningbo |

| density: | 0.97 g/cm3 | color: | white |

UHMWPE Fiber

UHMWPE yarn is one of the three high-tech fibers (specifically carbon fiber, aramid and UHMWPE), and in addition, it is an ultra-strong polyethylene fiber that provides maximum strength and minimum weight. It is 10 times stronger than premium steel and 40% stronger than aramid fiber, both by weight. UHMWPE yarns float on water and are extremely durable and resistant to moisture, UV rays and chemicals. So the applications are more or less unlimited.

The basic characteristics of UHMWPE yarn are as follows.

* High strength: the strength is 10 times that of high-quality steel with the same section;

* High modulus: second only to super carbon fiber

* Low density: 0.97, can float on the water

*anti-UV

*Anti-corrosion --- anti-acid, anti-alkali, anti-seawater;

*Extraordinary anti-abrasion, flexibility, anti-bending.

Based on such superior performance of UHMWPE yarn, it has become one of the rapidly developing high-tech materials in recent years, widely used in safety protection, aviation, aerospace, navigation, electronics, weapons, shipbuilding, building materials, sports and other fields, medical treatment, etc. . Products made from this fiber include body armor, bulletproof helmets, financial vehicles, bulletproof shields, tanks, naval armor shields, parachute cables, marine engineering ropes for ships, climbing ropes, fishing nets and pedals, boats, sailboats and arrows, rackets, Skis, artificial joints and ligaments, safety shields, impact-resistant containers, etc. 1

1. Description

UHMW-PE is a super engineering plastic that may not be as well known as some other engineering plastics, but it outperforms its counterparts in many important areas. UHMW (aka UHMW-PE) has excellent wear resistance, excellent impact resistance, non-stick and self-lubricating properties, and excellent mechanical properties, even at low temperatures. UHMW products reduce noise from shock and vibration. It is a self-lubricating material that is resistant to chemical attack, corrosion and wear. It's food safe. Light weight, 1/8 of steel. Life is higher than steel. The wear resistance is 3 to 7 times that of carbon steel and stainless steel.

two. Ultra High Molecular Weight Polyethylene Properties

1-UHMWPE fiber weaving

2- High tensile strength

3- Any denier fiber can be used, any weight can be made

4-UV, wear-resistant, water-resistant

5- Non-toxic

6- Good quality

7- Low coefficient of friction

8-UHMW hardly absorbs water

9. Corrosion resistance

10. Wear-resistant and impact-resistant

11. Wear-resistant

12. High quality lining material for industrial material handling applications

3. Application of UHMWPE

3. Application of UHMWPE

1. Chemical engineering: corrosion-resistant and wear-resistant mechanical parts

2. Thermal power: coal conveying, coal storage, silo lining

3. Coal processing: sieve plate, filter, U-shaped underground coal drop chute

4. Concrete: cement raw material silo and finished product silo lining

5. Grain: grain storage room or chute lining

6. Mining industry: sieve plate, chute liner, wear-resistant and anti-stick parts

7. Food industry: star wheel, transmission timing bottle screw, bearing, guide rail

Rollers, guide rails, sliders, etc.

My name is Cathy, please feel free to contact me.

My name is Cathy, please feel free to contact me.

thank you for your support!

Related Products

-

High strength and high modulus Dyneema fabric

Product Description High strength and high modulus Dyneema fabric Style: One-way Weight per square meter: 120GSM, 140GSM, 160GSM, Width: 1.6m and 1.2m Fiber strength: 35 g/d Fiber density: 600D Product type: UD fabric Thread strength/breaking strength 38g/day width: 160cm, or customized. Fabric...... -

Customized 30-1500m width wear resistant fabric 130gsm 200gsm 240gsm 300gsm UHMWPE woven fabric high strength UHMWPE fabric

type: Woven fabrics Function: Anti-cut/anti-bite/wear-resistant/ Gross weight per piece: 1.000 kg Color: 1000D model: SWT-SLUR00052 figure: Lightweight/High strength/Cut resistant Brand Name: Sovetel toughness: High strength Wide: 30-1500 meters Sales Unit: Single item Material: UHMWPE fiber +...... -

Cut-resistant dog UHMWPE fabric 5-grade cut-resistant wear-resistant puncture-resistant knitted wear-resistant UHMWPE fabric

toughness: High strength density: 330 g/m², 550 g/m² Material: UHMWPE fiber + glass fiber + polyester fiber, UHMWPE fiber figure: Lightweight/High strength/Cut resistant Function: Anti-cut/anti-bite/wear-resistant/ process: knitting Origin: Guangdong, China feature: Lightweight, UV-resistant,...... -

1mm - 6mm UHMWPE core with polyester sheathed rope

Material: WHMWPE core with polyester jacket, UHMWPE fiber payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram Stranded wire: 16 shares brand: auspicious Place of origin: Jiangsu, China color: Gray, green, yellow, red, blue, black, etc. For people: unisex Packaging details: Using standard...... -

120gsm 130gsm 150gsm 160gsm 800d High Strength White Fiber Hppe Ud Uhmwpe Sheet 0.1mm Uhmwpe Soft Armor Fabric

usage: Personal safety density: 130-160gsm feature: Notch-proof, light-weight, UV-resistant, corrosion-resistant, impact-resistant, high-strength, radiation-resistant, abrasion-resistant Package: carton size: custom Serve: Accept OEM ODM brand: Influence port: Ningbo, Shanghai, Tianjin, Shenzhen...... -

2023 Ultralight Knife Resistant Aramid Fabric Uhmwpe Woven Fabric Roller Tents Uhmwpe Fabric 2022

size: custom Supply capacity: 3000 tons per month brand: Influence usage: Personal safety application: vest jacket suit backpack ID: Accept custom logo density: 130-160gsm toughness: High payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram Packaging Details: carton Serve: Accept OEM ODM...... -

High Performance Uhmwpe Yarns Dyneemas Apparel Uhmwpe Knitting Fabrics Woven Cut Resistant Uhmwpe Fabrics

model: UHMWPE Fabric-1 elongation: 200 days 400 days 1000 days width: 150cm Supply capacity: 3000 tons per month payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram Fineness: 100-2400D Function: impact resistance Packaging Details: carton feature: Cut resistance, light weight, UV...... -

Polyethylene Ballistic Lightweight Soft UHMWPE Ballistic UD Fabric

feature: Bulletproof, anti-cut, light weight, anti-ultraviolet, corrosion-resistant, impact-resistant, high-strength, radiation-resistant, wear-resistant color: bright white model: S-160/120/130gsm width: 162±2cm toughness: / appearance: Smooth Supply capacity: 10000 kg per month Fineness: /...... -

Hound Cloth High Quality Aramid Fabric Men Clothing Tear Resistant 2022 Uhmwpe Cut Resistant Clothing Fabric

payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram Packaging Details: carton Supply capacity: 3000 tons per month application: Cut Resistant Fabric color: multiple colour Origin: Zhejiang, China expiration of pay: TT model: uhmwpe fabric-1 feature: Cut resistance, light weight, UV...... -

Tactical Vest UHMWPE Ballistic Unidirectional Fabric Weight 140g Bullet Feature Material Fiber Source High Resistance Gear Plate Vest

brand: Mingda feature: Bulletproof, light weight, high strength, radiation resistance, wear resistance model: UHMWPE ballistic unidirectional fabric payment terms: L/C, Western Union, T/T port: Shenzhen/Guangzhou Packaging Details: One in the plastic bag, one outside the plastic bag width: 160cm......