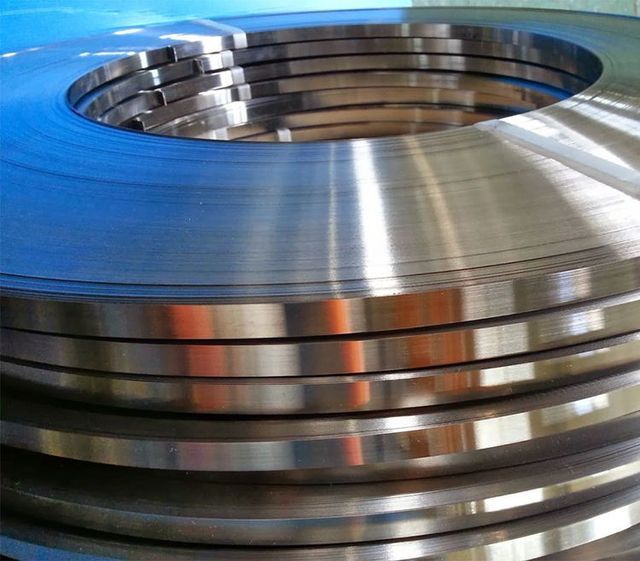

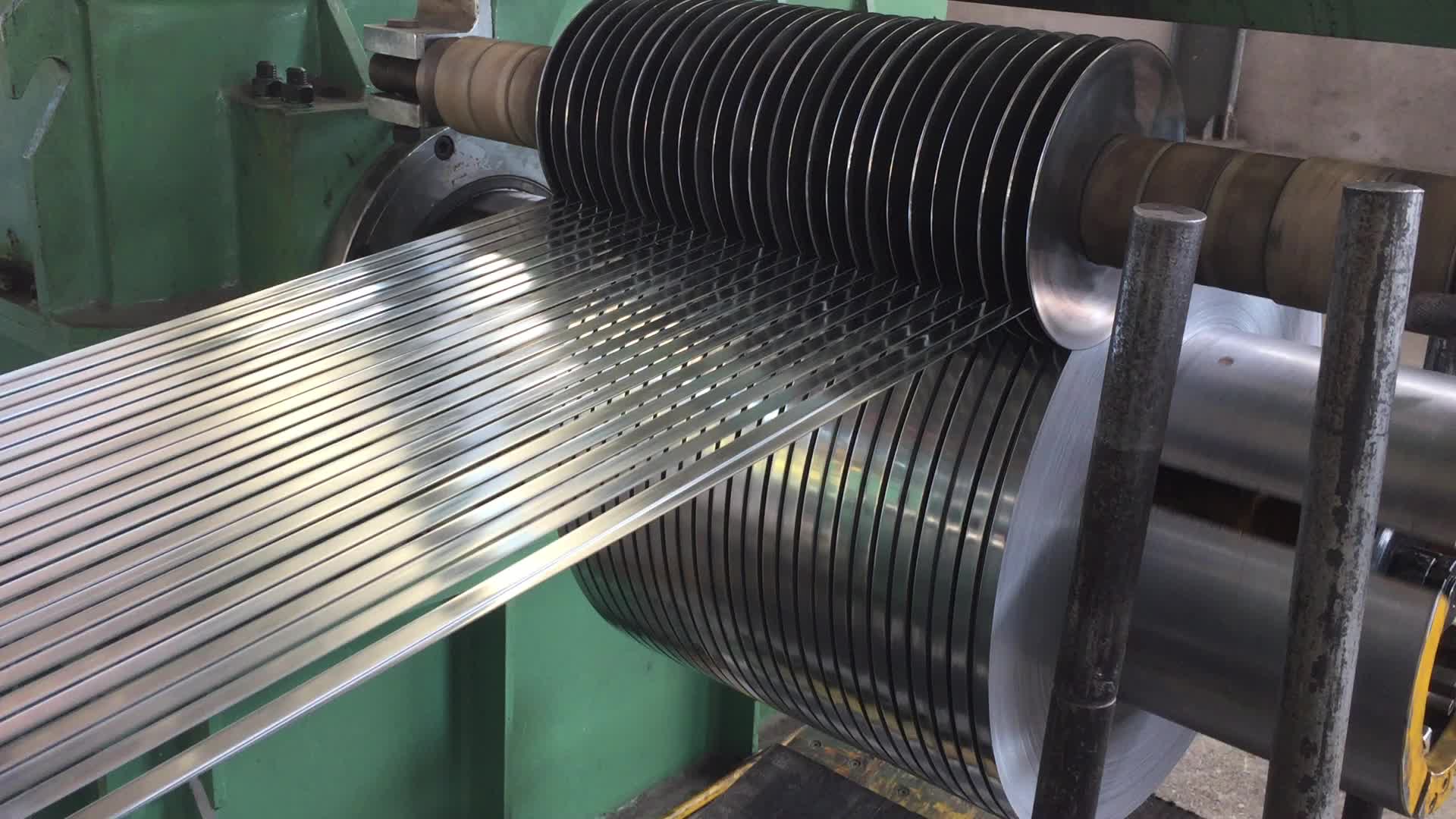

LC TT Payment 0.1mm 0.2mm 0.3mm 1mm 2mm 3mm cold rolled aisi 201 301 304 316 316l 410 420 421 430 439 stainless steel strip

- $688.00 /piece

- 1 piece

- Wuxi liansen Metal Technology Co.,Ltd

- Jiangsu, China

- Ms Josie Kong

Product Detail

| thickness: | 2-14mm | model: | strip |

| MOQ: | 1 ton | Processing services: | to cut |

| product name: | stainless steel belt | grade: | 200 series 300 series 400 series 500 series 600 series 900 series |

| tolerant: | ±1% | length: | 20mm-1500mm |

| payment terms: | L/C, T/T | port: | Shanghai Qingdao |

| Steel grade: | 301L,S30815,301,304N,310S,S32305,410,204C3,316Ti,316L,441,316,L4,420J1,321,410S,410L,436L,443,LH,L1,S32304,314,347,430,40,429S,4242C,3 , 420J2,436,445,304L,405,370,S32101,904L,444,301LN,305,429,304J1,317L | edge: | Edging\ Trimming |

| brand: | United Sen | width: | all available |

| Packaging Details: | According to customer requirements | technology: | Cold rolled hot rolled, cold rolled |

| The main purpose: | Deep drawn parts such as containers and acid pipelines | delivery time: | within 7 days |

| standard: | JIS, ASTM, DIN, EN, JIS, AISI, ASTM, GB, DIN, EN, etc., JIS AiSi ASTM GB DIN EN bs | Origin: | Jiangsu, China |

| Package preview: | Certification: | RoHS ISO IBR BV SGS | |

| Supply capacity: | 20,000 tons/month | surface: | BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

| sample: | free | Surface treatment: | TSHS 2B 2D THS BA 2BB No.3 TR No.1 NL etc. |

Product Description

Frequently used numbers | ASTM | Mechanical Specifications | ||||

Rm MPa | YS (MPa) | A5 | ||||

201 | 201 | ≥520 | ≥275 | ≥40 | ||

1Cr17Ni7 | ≥520 | ≥205 | ≥205 | |||

301 | 301 | ≥520 | ≥205 | ≥40 | ||

1Cr18Ni9 | ≥520 | ≥205 | ≥40 | |||

0Cr18Ni9 | ≥520 | ≥205 | ≥40 | |||

304 | 304 | ≥515 | ≥205 | ≥205 | ||

00Cr19Ni10 | ≥480 | ≥175 | ≥40 | |||

304L | 304L | ≥485 | ≥170 | ≥30 | ||

309S | 309S | ≥520 | ≥205 | ≥40 | ||

0Cr25Ni20 | ≥520 | ≥205 | ≥40 | |||

310S | 310S | ≥520 | ≥205 | ≥40 | ||

0Cr17Ni12Mo2 | ≥520 | ≥205 | ≥40 | |||

316 | 316 | ≥515 | ≥205 | ≥30 | ||

00Cr17Ni14Mo2 | ≥480 | ≥175 | ≥40 | |||

316L | 316L | ≥485 | ≥170 | ≥30 | ||

316Ti | 316Ti | ≥515 | ≥205 | ≥30 | ||

0Cr19Ni13Mo3 | ≥520 | ≥205 | ≥40 | |||

00Cr19Ni13Mo3 | ≥480 | ≥177 | ≥40 | |||

317L | 317L | ≥480 | ≥176 | ≥40 | ||

0Cr18Ni10Ti | ≥520 | ≥205 | ≥40 | |||

321 | 321 | ≥515 | ≥205 | ≥30 | ||

409L | ≥360 | ≥175 | ≥25 | |||

410 | 410 | ≥440 | ≥205 | ≥20 | ||

430 | 430 | ≥450 | ≥205 | ≥22 | ||

444 | 444 | ≥480 | ≥310 | ≥30 | ||

410S | ≥420 | ≥290 | ≥33 | |||

2205/S31803/F51 | 2205 | ≥450 | ≥620 | ≥15 | ||

2507/S32750/F53 | 2507 | ≥550 | ≥800 | ≥25 | ||

630 | ≥520 | ≥785 | ≥18 | |||

904L/N08904 | ≥490 | ≥216 | ≥35 | |||

thing | surface treatment | Surface treatment method | ||||

number one | human resources department | Heat treatment after hot rolling, picking, or handling with | ||||

NO.2D | no SPM | Method of heat treatment after cold rolling, surface rolls with wool or final skin calendering | ||||

NO.2B | After SPM | Appropriate cold gloss method for No.2 processed materials | ||||

bachelor | Bright annealing | Bright heat treatment after cold rolling to increase gloss and cold light effect | ||||

NO.3 | Bright, coarse grain processing | NO.2D or NO.2B processing wood NO.150-180 polishing abrasive abrasive belt | ||||

NO.4 | After CPL | NO.2D or NO.2B processing wood No. 150-180 polishing abrasive abrasive belt | ||||

240# | fine line sanding | NO.2D or NO.2B processing wood 240 polishing abrasive abrasive belt | ||||

320# | More than 240 grinding lines | NO.2D or NO.2B processing wood 320 polishing abrasive abrasive belt | ||||

400# | close to BA gloss | MO.2B Wood 400 polishing wheel polishing method | ||||

HL (hairline) | Polishing line with long continuous processing time | A process with a continuous polishing line in a belt of the right size (usually mostly 150-240 grit) as long as a human hair | ||||

NO.6 | NO.4 can't deal with reflection and extinction | NO.4 Processing materials for polishing Tampico wire drawing | ||||

NO.7 | High precision mirror processing | No. 600 Rotary Buffing Wheel with Polishing | ||||

NO.8 | Highest reflective mirror finish | The particles of the abrasive material are fine, polished sequentially, mirror polished with polishing | ||||

VIEW MORE

Related Products

-

Minimum thickness 0.05 mm, custom width stainless steel strapping straps

Product Description Product name Hot selling professional precision SS 310H stainless steel strap for binding Material 300 series width 8mm-650mm thickness 0.05mm-10mm length According to customer requirements standard DIN ISO JIS BA ANSI surface color pickled, bright, black Surface treatment...... -

AISI 201 304 316 401 430 Cold rolled stainless steel coil for industrial use

stainless steel strip Stainless steel strips are also called coiled strips, rolled materials, rolled plates, and plate coils. The hardness of the strips also varies. Features of stainless steel:1. Complete product specifications and various materials;2. High dimensional accuracy, up to ±0.1mm; 3....... -

0.05mm stainless steel coil 301 stainless steel spring plate has high hardness and good elasticity

standard: AISI ASTM JIS DIN GB, JIS, AiSi, ASTM, GB, DIN, EN delivery time: 15-21 days technology: cold rolling hot rolling, hot rolling surface: BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D Minimum order quantity: 1 kg Supply capacity: 100,000kg per month Package: Standard airworthy packaging Packaging...... -

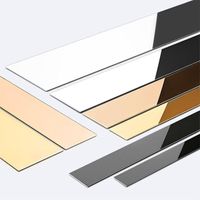

Soft material Ss 310 stainless steel strip/strip/roll

Finish: 2B/BA/HL/NO.4/8K/embossed/gold/rose gold/black gold Key words: stainless steel strip Advantage: Factory direct supply model: T-SS tape port: Shanghai or Tianjin Packaging details: Standard packaging is plastic bags and strapping, and can be customized; bundled with steel straps. End plastic.... -

Factory Price Ss 201 202 Grade J1 J2 J3 J4 Ba Cold Rolled Coil Stainless Steel Strip 2b Ba Hl Brushed 4K 6K 8K Surface Treatment

thickness: 0.3-16 mm Packaging Details: Standard transport export packaging width: 2mm-600mm model: 201 304 310s 316L 409 420 430 Surface finish: 2B sample: free! ! ! MOQ: 1 ton length: client needs brand: UHF gas generator Supply capacity: 8000 tons per month Origin: China Shanghai surface:...... -

Waterproof Thin Decorative Metal Bar Wall Decor Mirror Gold Gold Brushed Stainless Steel Flat Bar For Furniture/Door

technology: Bands tolerant: ±3% application: door/wall/mirror/furniture/wardrobe/photo frame delivery time: 8-14 days length: client needs length: client needs standard: Ace Packaging Details: Packing: 1) Large order: bulk. 2) Small order: tied with steel straps. 3) Woven cloth with 7 slats. 4)...... -

JIS SUS316 SUS316L SUS316Ti Stainless steel foil ribbon for necklaces

payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram application: Industry, construction, decoration, etc. Supply capacity: 5000 tons per week standard: JIS AISI ASTM GB DIN EN BS Surface treatment: Mirror surface, anodized, brushed, polished, polished, etc. Steel grade: 301L, 301, 310S,...... -

304/316/316L stainless steel coil cold rolled stainless steel strip

model: SS008 delivery time: 8-14 days Advantage: exact size Package preview: sample: free of charge Surface treatment: 2B/BA/HAIRLINE/8K/NO.4 port: Qingdao, Shanghai, Ningbo, etc. technology: cold-rolled hot-rolled, hot-rolled, cold-rolled grade: 201 301 409L 430 Key words: stainless steel coil...... -

201 stainless steel belt 19mm full hard stainless steel belt

usage: building decoration Packaging Details: Standard export package with waterproof paper + metal tray + angle steel protection + steel belt or Tianjin/Shanghai port according to customer requirements product name: 201 stainless steel strip Steel grade:...... -

Cold rolled coils for stainless steel grade 304 ASTM standard stainless steel strip

type: Sheet Coil Steel grade: 301,310S,410,316L,441,316,420J1,321,410S,347,430,304,409L,420J2,304L expiration of pay: 30% T/T advance payment + 70% balance tolerant: ±3% surface: BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D technology: Cold Rolled Finishes, Strips width: 5mm-1800mm application: construction......