Roofing material color coated steel sheet coil / PPGI / PPGL color coated galvanized steel sheet coil

-

$625.00 / 1 - 99 pieces

$586.00 / 100 - 999 pieces

$536.00 / >=1000 pieces - 1 piece

- Jiangsu Zhongzesheng Steel (group) Co., Ltd.

- Jiangsu, China

- Mr

Product Detail

| coating: | Z10-Z29 | Supply capacity: | 1 million tons per month |

| brand: | Nakazawa | expiration of pay: | 30% TT advance payment + TT 70% balance |

| Key words: | Pre-coated PPGI color coated coil | application: | Make pipes, cut sheets, make gadgets, make corrugated sheets, make containers, make fences |

| Processing: | Cold rolling + hot dip galvanizing | payment terms: | L/C, Western Union, D/P, D/A, T/T |

| Origin: | Jiangsu, China | delivery time: | 8-14 days |

| Paint Thickness: | custom made | product name: | PPGI coil |

| Surface finish: | color prepainted | thickness: | 0.16mm-0.7mm |

| width: | 600-1250mm | MOQ: | 1 ton |

| Material: | DX51D~DX53D | tolerant: | ±1% |

| standard: | ASTM | length: | roll or custom |

| Packaging Details: | 1. Packed in bundles, the weight of each bundle is less than 3 tons, and for small outer diameter steel pipes, 4-8 steel strips are used for each bundle. 2. After bundling, cover with polyethylene tarpaulin. 3. Paint black paint on each pipe and tie into bundles | hardness: | hard |

| type: | steel coil | Package preview: | |

| Certificate: | API, JIS, ISO9001 | combo: | Standard Airworthy Packaging |

| port: | Tianjin, Qingdao, Shanghai, | Processing services: | Welding, punching, cutting, bending, decoiling |

| Raul Color: | custom made | raw material: | Galvanized Coil |

| grade: | DX51D DX52D |

product description

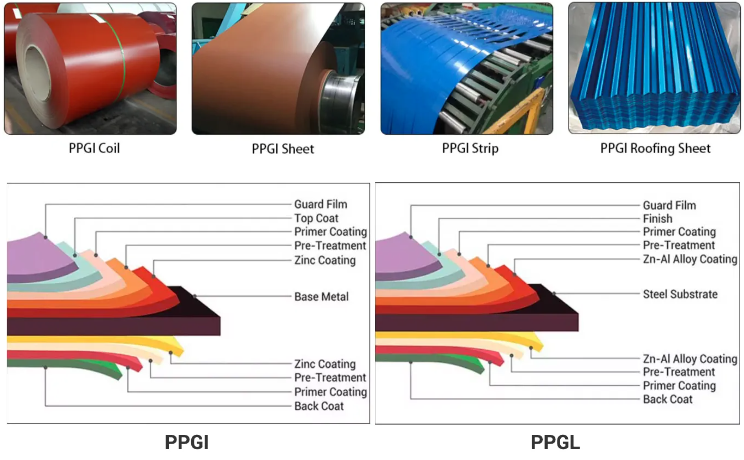

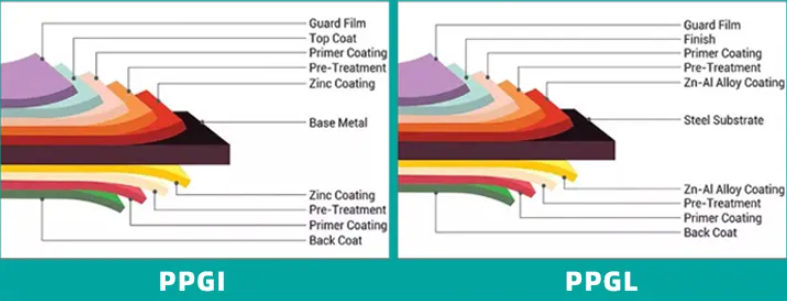

What are PPGI and PPGL?

PPGI (Pre-painted Galvanized Iron) and PPGL (Pre-Painted Galvalume) are two types of coated steel sheets that are widely used in various industries such as construction, automobiles, electrical appliances, and furniture. Both PPGI and PPGL are produced by applying a paint or other protective coating to the steel sheet or coil before it is formed into a final product. This process ensures that the steel is protected from corrosion and other damage, while also enhancing its aesthetics.

PPGI is produced by applying a paint or other protective coating to galvanized steel sheets or coils. This type of coated steel is known for its excellent corrosion resistance, durability and versatility. PPGI is available in a variety of colors and finishes, making it a popular choice for building facades, roofing and other architectural applications.

PPGL, on the other hand, is made by coating a steel sheet or coil with a layer of aluminum-zinc alloy instead of using a zinc coating like PPGI. This type of coated steel is highly resistant to corrosion and has excellent heat resistance, making it suitable for use in high temperature applications.

Both PPGI and PPGL provide cost-effective solutions for various industries. They provide long-lasting natural protection, while also offering a variety of colors and finishes to meet the specific needs of different applications.

Product parameters

technical standard | EN10147/EN10142/DIN 17162/JIS G3302/ASTM A653 |

steel grade | DC51D+Z, DC52D+Z, DC53D+Z, S280GD+Z, S350GD+Z, S550GD+Z, DC51D+AZ, DC52D+AZ, S250GD+AZ, S300GD+AZ, S350GD+AZ, S550GD+AZ, SECC, SECE, BLCE+Z, BLDE+Z, BUSDE+Z or customer requirements |

base steel | Hot-dip galvanized steel, hot-dip galvanized steel, electro-galvanized steel |

thickness | 0.12-6.0mm |

width | 600-1500mm |

surface color | RAL, wood grain pattern, camouflage pattern, stone pattern, matte pattern, high gloss pattern, flower pattern, etc. |

quality | Passed SGS, ISO certification |

Coil weight | 3-20 tons per roll |

pack | The inner packing is waterproof paper, the outer packing is galvanized steel plate or coated steel plate, add side guards, and then use the outer packing Seven layers of steel belt. or according to customer requirements |

Export market | Europe, Africa, Central Asia, Southeast Asia, Middle East, South America, North America, etc. |

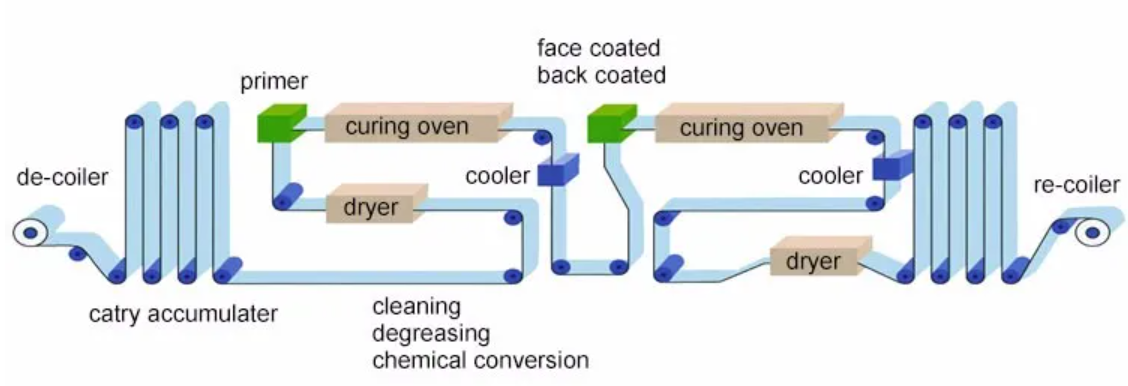

Product process

PPGI and PPGL production line diagram

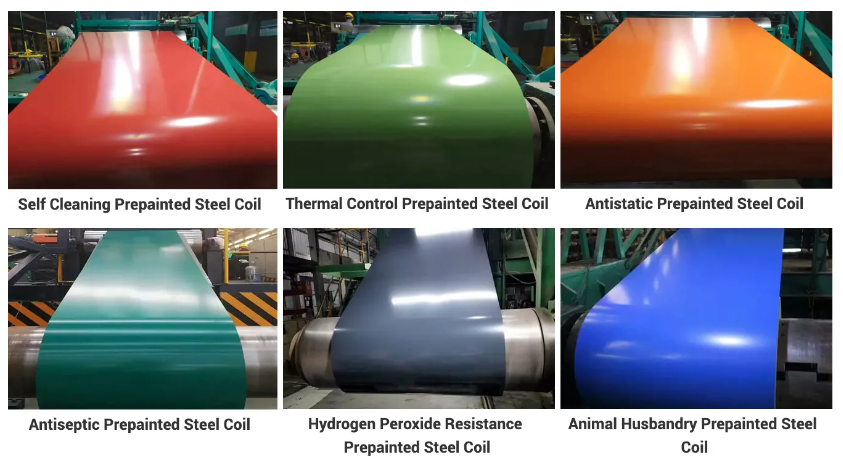

detailed image

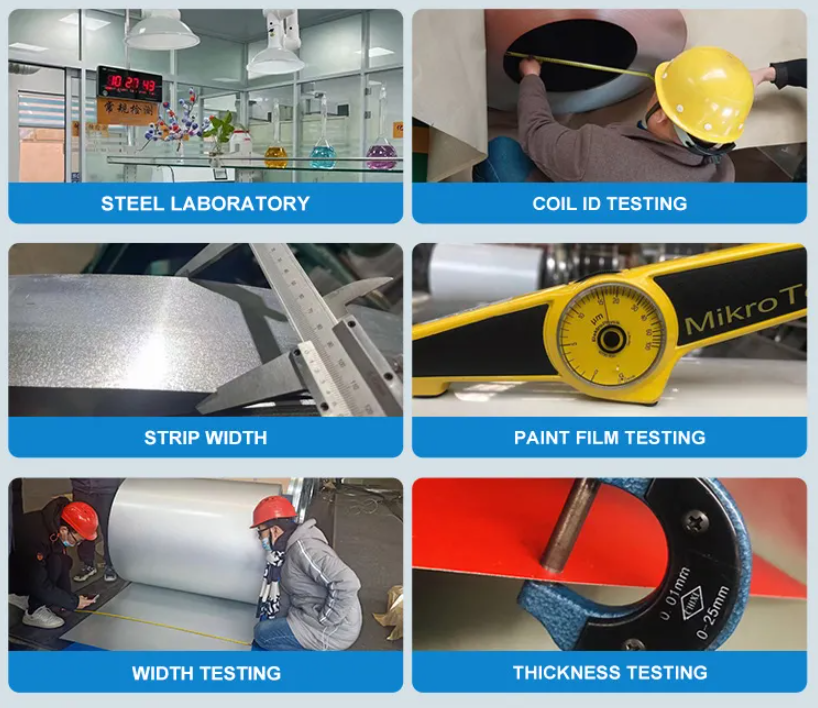

QC

VIEW MORE

Related Products

-

0.4*1220mm PE color coated metal pre-coated galvanized rion ppgi steel coil price per ton for roof sheet

Film thickness: 20/10 microns Certificate: ISO9001 coating: Z61-Z80 Payment Terms: L/C, Western Union, T/T Supply Ability: 10000 tons/month width: 900-1250 mm standard: EN tolerant: ±1% Origin: Tianjin, China Brand Name: Show Wisdom RAL Color: White Payment Deadline: Telegraphic transfer; letter of.... -

Pre-coated ISO cut hot rolled RAL galvanized color coated steel coil for sale

technology: hot rolled Packaging details: 1. Large outer diameter: bulk 2. Small outer diameter: steel band packaging 3.7 pieces of woven cloth 4. According to customer requirements coating: Z41-Z60 Place of origin: Hebei china length: custom product: 5000 tons/month delivery time: 31-45 days...... -

China high quality color coated steel coil PPGL PPGI Q235 G550 color coated galvanized steel coil

MOQ: 5 tons hardness: full hard port: Tianjin. Qingdao, Shanghai Origin: Shandong Province, China Packaging Details: According to your requests brand: He Fa thickness: 0.1-6mm payment terms: L/C, Western Union, D/P, D/A, T/T delivery time: within 7 days type: steel coil, color coated steel plate,...... -

Prime 0.2mm 0.3mm 0.4mm color coated corrugated sheet ppgi color coated roof panel

thickness: 0.1-0.3 Processing services: Welding, punching, cutting, bending, decoiling Certificate: ISO9001:2008, API, ce, RoHS, SNI, BIS, SASO, PVOC, SONCAP, SABS, sirm, tisi, KS, JIS, GS, ISO9001 usage: building structure tolerant: ±10% Packaging Details: Shipping package Substrate: DX51D DX52D...... -

Prepainted Prepainted Coil Ppgi Ppgl Galva Ppgi Prepainted Coil

MOQ: 5 tons brand: and hair delivery time: within 7 days coating: Z10-Z29 Processing services: Bending, welding, uncoiling, cutting, punching, welding, punching, cutting, bending, uncoiling application: building, building, boiler, vessel plate, ship plate, make pipe, cut plate, make gadget, make...... -

DIN 17162 cold rolled container steel ppgl high quality galvanized iron steel coil pre-galvanized steel

thickness: 0.12-6mm or as your request pricing term: 30% T/T advance payment + 70% balance Material: ASTM/AISI/SGCC/CGCC/TDC51DZM/TDC52DTS350GD/TS550GD/DX51D+Z Q195-q345 coating: Z61-Z80 surface: Prepainted Packaging Details: Comply with sea packing standard type: steel coil length: According to...... -

China Supplier PPGI Dx51D Color Coated Pre-painted Galvanized Steel Coil

delivery time: 7-15 days application: Make pipes, cut sheets, make gadgets, make corrugated sheets, make containers, make fences Processing services: Welding, punching, cutting, bending, decoiling MOQ: 1 ton tolerant: ±1%,±1% RAL color: all quality: high quality brand: Jigang Origin: Shandong China.... -

Free Sample Custom Color Prepainted Galvalume Steel Coils Made in Shandong

Origin: Shandong China Processing services: Welding, punching, cutting, bending, decoiling Package preview: payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram tolerant: ±1% type: steel coil coating: Z10-Z29 product name: Ppgi Galvanized Steel Coil application: Make pipes, cut sheets, make..... -

China popular color PPGI metal galvanized steel roof steel plate galvalume corrugated roof

width: 700-1500MM type: steel plate hardness: medium hard standard: National standard payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram tolerant: ±1% Supply capacity: 1000 metric tons per week Processing services: Cutting, welding, punching, cutting, bending, decoiling Material:...... -

PPGI PPGL Prepainted Zinc Aluminum Zinc Steel Coil Cold Rolled Prepainted Galvanized Steel Sheet Material Roofing Construction

Supply capacity: 3000 tons per month hardness: full hard Processing services: Welding, punching, cutting, bending, decoiling MOQ: 1 ton RAL color: or as per your request length: at your request, at your request standard: ASTM GB AISI DIN JIS EN type: steel coil application: make pipes, cut sheets,.....