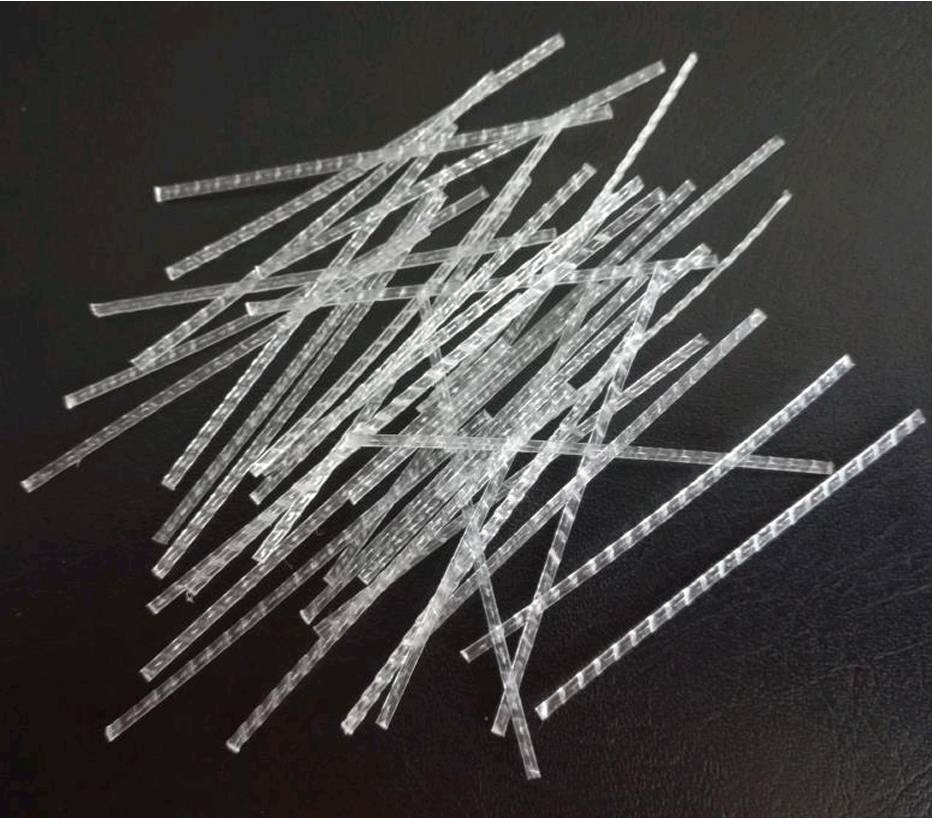

Lower price pp plastic fiber 50mm and 65mm length concrete fiber for reinforcement of concrete and mortar

- $1.52 /kilogram

- 1 kilogram

- Shandong Jinhongyao Engineering Material Co., Ltd.

- Shandong, China

- Mr David Shi

Product Detail

| type: | Polypropylene | Melting point: | 160 - 170 |

| Packaging Details: | wooden packaging | Elastic Modulus: | 3500 MPa |

| Supply capacity: | 1000 tons per week | model: | 50mm-65mm |

| application: | concrete reinforcement | brand: | golden red medicine |

| Elongation at break: | 15%-25% | Material: | 100% polypropylene |

| Origin: | Shandong Province, China | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| density: | 0.91 g/cm3 | Fiber Length: | 2-30mm |

| Package preview: | color: | white | |

| port: | Qingdao or request | length: | 50mm-65mm |

| Acid, alkali and salt resistance: | 95% strong | use: | concrete, bridge construction |

| tensile strength: | 450 MPa | Ignition point: | 280-350 |

Product Description

Material | 100% polypropylene |

use | bridge construction |

density | 0.91 g/cm3 |

melting point | 160 - 170 |

fiber length | 2-30mm |

Elastic Modulus | 3500 MPa |

tensile strength | 450 MPa |

ignition point | 280-350 |

elongation at break | 15%-25% |

Acid, alkali, salt | 95% strong |

birthplace | China |

Shandong | |

brand | golden red medicine |

model | 12mm |

application | concrete reinforcement |

length | 12mm |

color | white |

type | Polypropylene |

product information

pp plastic steel fiber, this product is a substitute product developed for steel fiber, taking into account some characteristics of synthetic fiber. Compared with steel fiber, it has the characteristics of corrosion resistance, easy dispersion, convenient construction, and no damage to mixing equipment. The product is made of synthetic resin as raw material and processed by special technology and surface treatment. It has the advantages of high breaking strength, good dispersion in concrete, and strong holding power. It has the characteristics of low tensile strength, small ultimate elongation and brittleness.

It has the properties of tensile, shearing, cracking, fatigue and high toughness. it has been

It is used in construction, road and bridge, water conservancy engineering and other engineering fields.

It has the properties of tensile, shearing, cracking, fatigue and high toughness. it has been

It is used in construction, road and bridge, water conservancy engineering and other engineering fields.

use:

1. Dosage: It is recommended that the volume dosage of imitation steel fiber be 0.3%-0.9%, that is, the dosage per cubic concrete is 3kg--9kg.

2. Length selection: general anti-cracking reinforced concrete is 30mm-50mm; 20mm-30mm is used to add to shotcrete.

3. Mix ratio design: It is not necessary to change the gradation ratio parameters of concrete for general application. You can refer to "Code for Steel Fiber Concrete Structure and Construction" CECS38:92. For special applications, selection and design require testing. Considering that concrete will cause tiny cracks due to factors such as drying shrinkage, drying shrinkage, and temperature changes, 1kg of monofilament ultrafine fibers can be added to the concrete for better results.

4. Mixer type selection: choose a double-shaft horizontal forced mixer.

5. Feeding and mixing process: First put in gravel, then put in anti-cracking tendons, then put in sand, stir to make the anti-cracking tendons fully disperse, then put in cement and water, and stir evenly according to the conventional process. It can also be constructed according to the sequence of conventional technology input, but the mixing time should be extended appropriately to make the anti-cracking reinforcement disperse evenly.

6. Forming and curing process: no special requirements, and the tape time can be extended as appropriate. When plastering, the concrete surface should be slightly passivated before proceeding to avoid it being brought out. The maintenance should still be carried out according to the requirements of ordinary concrete.

7. Packaging: regular packaging 1.0kg/bag, or according to user requirements.

1. Dosage: It is recommended that the volume dosage of imitation steel fiber be 0.3%-0.9%, that is, the dosage per cubic concrete is 3kg--9kg.

2. Length selection: general anti-cracking reinforced concrete is 30mm-50mm; 20mm-30mm is used to add to shotcrete.

3. Mix ratio design: It is not necessary to change the gradation ratio parameters of concrete for general application. You can refer to "Code for Steel Fiber Concrete Structure and Construction" CECS38:92. For special applications, selection and design require testing. Considering that concrete will cause tiny cracks due to factors such as drying shrinkage, drying shrinkage, and temperature changes, 1kg of monofilament ultrafine fibers can be added to the concrete for better results.

4. Mixer type selection: choose a double-shaft horizontal forced mixer.

5. Feeding and mixing process: First put in gravel, then put in anti-cracking tendons, then put in sand, stir to make the anti-cracking tendons fully disperse, then put in cement and water, and stir evenly according to the conventional process. It can also be constructed according to the sequence of conventional technology input, but the mixing time should be extended appropriately to make the anti-cracking reinforcement disperse evenly.

6. Forming and curing process: no special requirements, and the tape time can be extended as appropriate. When plastering, the concrete surface should be slightly passivated before proceeding to avoid it being brought out. The maintenance should still be carried out according to the requirements of ordinary concrete.

7. Packaging: regular packaging 1.0kg/bag, or according to user requirements.

feature

1. Effectively reduce the risk of concrete cracks and improve the tensile, flexural and flexural strength of concrete;

2. In the event of severe natural disasters such as earthquakes, losses can be reduced;

3. Reduce the fatal defects of concrete and improve the impermeability of concrete;

4. Protect steel bars from corrosion and improve the durability of concrete structures;

5. Increase the wear resistance of concrete;

6. Significantly improve fatigue resistance;

7. It can prevent tire damage when used on the road.

1. Effectively reduce the risk of concrete cracks and improve the tensile, flexural and flexural strength of concrete;

2. In the event of severe natural disasters such as earthquakes, losses can be reduced;

3. Reduce the fatal defects of concrete and improve the impermeability of concrete;

4. Protect steel bars from corrosion and improve the durability of concrete structures;

5. Increase the wear resistance of concrete;

6. Significantly improve fatigue resistance;

7. It can prevent tire damage when used on the road.

Application field

VIEW MORE

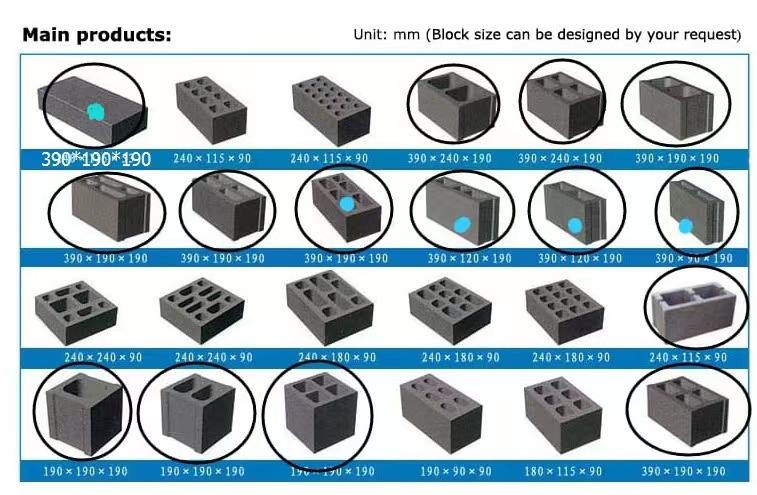

Related Products

-

PP polypropylene short fiber for geotextiles

Product Description Product name Polypropylene short fiber Material 100% polypropylene Fineness 6D fiber length 64mm color White/black or customer choice brand GT application Product packaging manufacturing technology Company information FAQ Q: Are you a manufacturer or trader.We are a manufacturer.... -

Construction Chemicals Materials Mixed Fiber Concrete Macro Concrete Fiber

Fiber length: 30,50,54mm,36mm 48mm,50mm product name: Polypropylene twisted fiber density: 0.91+/-0.01g/cubic centimeter tensile strength: >400Mpa Supply capacity: 1000 tons per month brand: China payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram, PayPal Place of origin: Hunan, China...... -

PP fiber concrete for construction with tile adhesive, PP fiber for cement mortar

Package preview: Sales unit: Single product Fiber length: 6mm, 3mm, 6mm, 9mm, 12mm, 16mm, 19mm Minimum order quantity: 1 ton pack: 25kg/bag or customized sample: free of charge Single piece packaging size: 20X15X10cm Gross weight of single piece: 1.500kg Packaging details: 25KG/bag, private label...... -

Black nylon short fiber for nylon fiber spinning in China factory

length: 38mm~120mm Package preview: pattern: raw Fiber type: staples sample: free Supply capacity: 400 tons per month Place of origin: Zhejiang, China brand: Jiu Sheng Hua Xian payment terms: L/C, D/P, wire transfer port: Ningbo/Shanghai Yarn count: 1.2D~80D Certificate: OEKO-TEX standard Material:.... -

Glass Fiber Reinforced Concrete Low Price Fiberglass Polypropylene For High Strength Concrete Rope

use: specific port: Shandong Customized service: accept color: white product name: concrete fiber Elongation at break: minimum 10% Fiber Length: 3mm, 6mm, 9mm, 12mm, 16mm, 19mm, 6mm Origin: Shandong Province, China Packaging Details: wooden packaging payment terms: L/C, Western Union, D/P, D/A,...... -

Synthetic crude fiber alkali-resistant twisted polypropylene fiber for concrete reinforcement

tensile strength: ≥3400MPa Ignition point: 560°C Origin: SHN Acid, alkali and salt resistance: strong Melting point: 160-170℃ density: 0.91 g/cm3 Supply capacity: 1000 metric tons per month Fiber Length: 54 mm Packaging Details: Woven bag or pallet 12 tons/20GP, 28 tons/40hq port: Qingdao...... -

Ruyuan Chemical Concrete Cement Additive Polypropylene Short Fiber Polypropylene Fiber Polypropylene Microfiber

Melting point: 189 °C(lit.), 165 to 175 degrees Celsius tensile strength: 2.5-5.5Cn/dtex,>400MPA port: Tianjin density: 0.9 g/ml (l) at 25 °C use: Concrete, cement mortar, interior (exterior) wall coating, concrete, concrete/bridge/road Packaging Details: 20kg/bag 950mm*400mm*130mm Ignition point:..... -

High Quality Polypropylene Fiber Reinforced Concrete Synthetic Fiber Concrete Fiber Mesh Affordable Price

model: Fiber Concrete - FF Ignition point: >400℃ Elastic Modulus: > 3.5 Backlog Elongation at break: < 12% density: 0.91 g/cm3 Supply capacity: 100,000 kg per month cross section: Rectangle Melting point: 160°C Fiber Length: 6mm, 12mm, 20mm, 24mm, etc. tensile strength: >600MPa Material: 100%...... -

Concrete Reinforced Polypropylene Coarse Synthetic Fiber

payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram Origin: Hebei china color: white Acid, alkali and salt resistance: 95% strong use: concrete, filling material, concrete Melting point: 160 - 170 brand: Tianhuibao Ignition point: 280-350 density: 0.91 g/cm3 model: Polypropylene fiber,...... -

cheap price white pp polypropylene staple fiber for spinning

Packaging Details: PP woven bag compression packaging port: Shanghai model: GT-ZYB78 Package preview: quality: 100% virgin Melting point: 165~173℃ major: Flame retardant, high toughness, hydrophilic, hydrophobic, Fiber pack weight: About 260 kg per bag density: 0.91 g/cm3 MOQ: 260 kg Acid and......