Plastic High Impact Polystyrene Price HIPS 622P Manufacturer

- $0.60 / >=25 kilograms

- 25 kilograms

- Hangzhou Yuhang Trade Co., Ltd.

- Zhangjiang, China

- Mr de yong

Product Detail

| model: | Buttocks 622P | Approach: | injection molding |

| place of origin; place of origin: | China Shanghai | brand: | Shanghai Petrochemical |

| Packaging Preview: | port: | Shanghai, Ningbo | |

| Supply capacity: | 50 tons per day | Packaging Details: | 25kg/bag, standard packaging. |

| payment terms: | wire transfer | use: | Household Supplies Food Packaging Packaging |

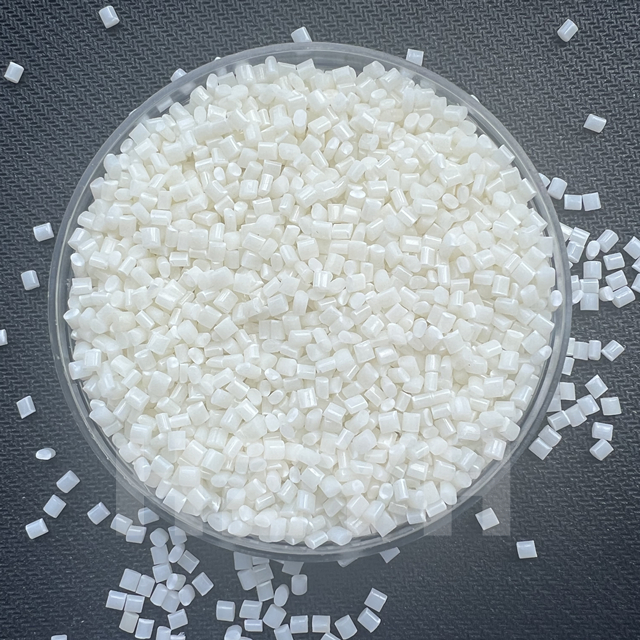

| feature: | huge influence | form: | particle |

| Material Status: | normal cycle |

physical properties | Test Conditions | attribute value | unit | testing method |

investment index | 15.0 | g/10 min | ASTM D1238 | |

investment index | 5.5 | g/10 min | ASTM D1238 | |

proportion | 23℃ | 1.05 | No | ASTM D792 |

Mechanical behavior | ||||

tensile strength | 250 | MPa | ASTM D638 | |

elongation | 40 | % | ASTM D638 | |

Flexural modulus | 2.0*10^4 | kg/cm² | ASTM D790 | |

Flexural strength | 380 | kg/cm² | ASTM D790 | |

Thermal performance | ||||

Heat distortion temperature | 82 | °C | ASTM D648 | |

Vicat softening point | 98 | °C | ASTM D1525 | |

impact characteristics | ||||

Izod impact strength | 1/4" | 9.0 | kg-cm/cm | ASTM D256 |

Izod impact strength | 1/8" | 11.0 | kg-cm/cm | ASTM D256 |

flammable | ||||

burning rate | 1/16"HB | No | File No. E56070 UL&C CL | |

hardness | ||||

Rockwell hardness | large | 75 | ASTM D785 | ASTM D785 |

Introduction to polystyrene

Polystyrene is one of the oldest thermoplastic polymers produced industrially and is a versatile product with many uses. The advantages of this bright pure amorphous plastic are that it is easy to process, rigid, dimensionally stable and transparent, but its low impact strength limits its application. High impact polystyrene is made by grafting small amounts of polybutadiene onto a polystyrene matrix. It has an "island structure", a plastic matrix and a rubber dispersed phase. It has many characteristics: 1. Impact-resistant polystyrene is a thermoplastic resin; 2. It is odorless and tasteless, the material is hard, and the dimensional stability after molding is good; 3. Excellent high dielectric insulation; 4. Non-high-quality low water absorption material 5. Good gloss and easy to color.

high impact polystyrene

High-impact polystyrene, also known as HIPS, is a thermoplastic material made from elastomer-modified polystyrene. A two-phase system consisting of a rubber phase and a continuous polystyrene phase has developed into an important polymer commodity in the world. This general-purpose product has a wide range of impact properties and processing properties, allowing it to be used in a wide range of applications. Such as in the automotive, equipment, electrical products, furniture, household appliances, telecommunications, electronics, computers, disposable products, pharmaceuticals, packaging and entertainment markets.

Polystyrene Properties

The relative density of HIPS is 1.04~1.06, and the thermal deformation temperature is 70~84℃. The tensile strength of HIPS is about 15~30MPa, and the elongation is 35~60%. It increases with decreasing temperature and increasing strain rate, similar to rubber toughened systems. HIPS behaves somewhat like a viscoelastic solid and creeps when exposed to constant tensile stress. Creep decreases with increasing molecular weight and generally increases with increasing rubber content. The creep behavior of HIPS is strongly dependent on the average molecular weight (Mw). The bending strength is 29.4~50 MPa, the impact strength is 0.09~0.16N/M, the Vicat softening point is 84~100℃, and the melt index is 2~9g/10min. The heat resistance of a HIPS element depends on its shape, production conditions, heat source type and heating duration, and is also affected by the HIPS grade.

VIEW MORE

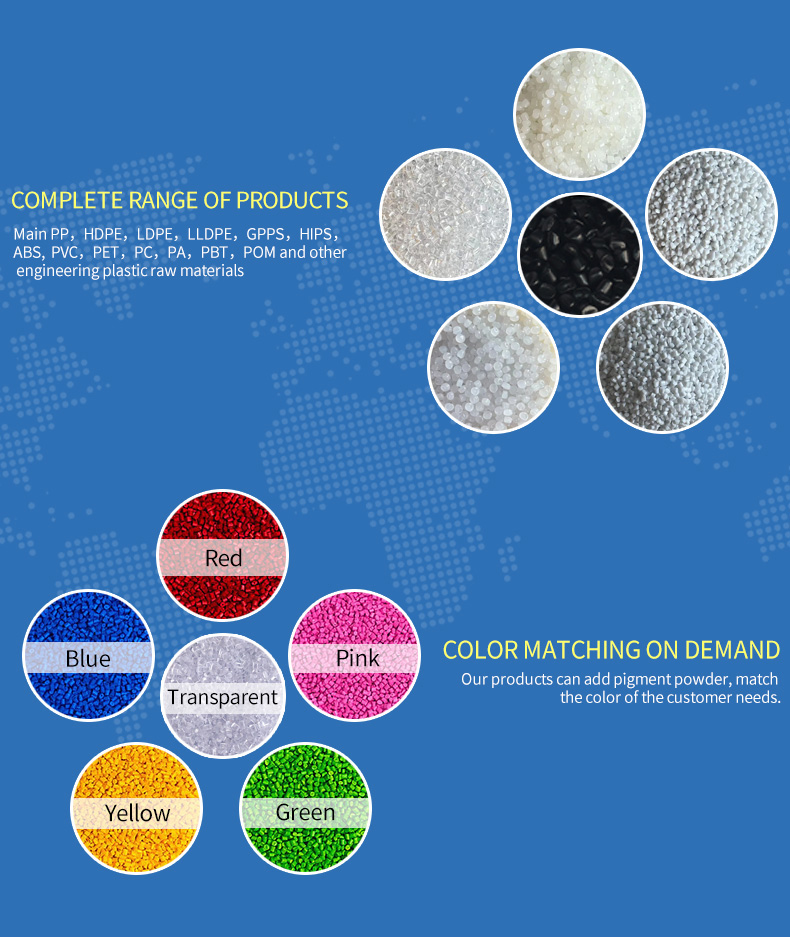

Related Products

-

Injection molding black Repro HIPS granular Hips plastic raw material

Product Description HIPS features HIPS has the characteristics of good toughness, fatigue resistance, weather resistance, low water absorption, high dielectric strength, good electrical properties, dimensional stability, good formability, and good chemical resistance. Company Profile Packaging and..... -

SGS approved virgin and recycled HIPS resin, HIPS granules, HIPS manufacturer/factory price manufacturer

Material: HIPS plastic raw material particles quality: high quality application: Home electrical applications Packaging details: 25kg bag port: any port thing: High impact polystyrene resin brand: Zhongzao appearance: Transparent particles Place of origin: Hebei china grade: Injection molding grade.... -

Virgin HIPS Plastic High Impact Polystyrene Feedstock Granules

application: energy industry product name: High impact polystyrene plastic pellets model: Hip cup waste, HIPS color: natural color port: Tianjin type: Virgin butt granules Packaging details: 25KG/bag, 50KG/bag, or customized according to customer needs. Package preview: payment terms: wire transfer.... -

HIPS plastic/Kumho HI-425E/disposable cups/various food packaging/washing machine parts

port: Shanghai, Ningbo model: HI-425E,HI-425E grade: Injection molding grade port: Ningbo brand: Kumho, South Korea color: milky Package preview: appearance: Milky white grains density: 1.04 payment terms: Letter of credit, wire transfer Material: buttocks The melt flow rate: 4.5 Package: 25kg/bag..... -

EPS expanded polystyrene particles EPS foam resin

Package preview: product name: earnings per share grade: virgin Supply capacity: 1000 tons per month sample: free color: white Origin: Hebei china payment terms: L/C, Western Union, T/T pack: 25kg/bag brand: Dragon King Packaging Details: 25kg/bag port: Tianjin MOQ: 1MT Product Description...... -

Recycled Plastic Granules HIPS Black Gloss Granules Antistatic HIPS Granules

application: Automobile hubs, corrugated pipes, etc. Name: buttocks Package preview: model: BS-2022-HIPS brand: according to pack: 25kg per bag Material: HIPS/GPPS Plastic Granules port: Tianjin feature: glass fiber filled payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram Packaging...... -

Natural color HIPS resin particles HP8250 HIPS plastic raw material polystyrene PC/PET particles

port: Shanghai, Qingdao MOQ: 25 kg Origin: Henan, China brand: Sinopec Packaging Details: 25kg/bag wooden pallet with moisture-proof film quality: Excellent appearance: Toy sample: available shape: Granules - Granules density: 1.05 g/cm Package preview: processing method: injection molding Supply...... -

HIPS particles with good toughness virgin/Total 3341/industrial applications/flakes

port: Ningbo Origin: french, french Material: buttocks payment terms: L/C, T/T model: 3341,3341 color: milky The melt flow rate: 3 Packaging Details: 25kg/bag Supply capacity: 50 tons per day Package preview: density: 1.04 Package: 25kg/bag port: Shanghai, Ningbo brand: all appearance: Milky white..... -

General Plastics High Impact Polystyrene Raw Material Virgin Injection Grade Hips Granules 514

Supply capacity: 5000 tons per week pack: 25kg/bag product name: HIPS plastic pellets brand: Hong Xu density: 1.04 The melt flow rate: 4.5g/10min port: Tianjin grade: injection molding Package preview: model: buttocks payment terms: wire transfer Packaging Details: 25kg per bag, the packaging can...... -

HIPS Polystyrene Granules Flame Retardant HIPS Granules High Impact Polystyrene Hips

grade: Injection grade Supply capacity: 200,000 kg per year Package: 25kg/bag application: General injection molding products density: 1.05 g/cm3 Packaging Details: Bag sample: usable feature: thermoplastic material MOQ: 5 tons color: natural color Material: Virgin HIPS Plastic Granules brand: Anlu....