Customize High Purity Production Anti-Oxidation Graphite Molds

- $5.00 /piece

- 1 piece

- Suzhou Dasen Electronics Material Co., Ltd.

- Jiangsu, China

- Ms Sen Da

Product Detail

| application: | Metallurgical industry | Packaging details: | Plywood box or as per customer's requirement. |

| Porosity(%): | 12% | brand: | Data service network |

| Advantage: | lubricating | product name: | Custom graphite mold |

| Material: | High purity graphite material | port: | Shanghai |

| model: | Graphite mold DSN1000 | usage: | Welding processing |

| Origin: | Jiangxi, China | Supply capacity: | 20,000 pieces per month |

| Ash content: | 0.2%-0.3% | Key words: | Isostatic graphite mold |

| Bulk density (g/cm3): | 1.68-1.85g/cubic centimeter | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| Compressive strength: | 26-65Mpa | Resistance (μΩ.m): | 10 micro ohms |

| Grain size: | 0.02mm-4mm | Bending strength: | 15-40MPa |

| technology: | Compression molding | color: | Black |

| Size and shape: | Custom processing |

phosphorusProfessional solution provider for pyrolytic graphite, silicone pads, die-cutting, special graphite, ceramic filter membranes, etc.

Serving communications, industrial consumer electronics and medical care, new energy vehicles, machinery, and environmental engineering.

Used in flexible circuit boards, backlight modules, touch panels, mechanical hardware, finished product assembly and environmental engineering industries

Four factories: Jiangsu, Jiangxi, Anhui, and Qingdao.

Certificates: ISO9001, IATF16949, ISO14001, UL...

Suzhou Sales Center

Dasen is a high-tech enterprise engaged in the research, development, production and sales of pyrolytic graphite, special graphite, die cutting, silicone pads and flat ceramic membranes. The pyrolytic graphite factory is located in Jiangxi; the special graphite is in Shandong; the silicone pad factory is in Jiangsu, and the ceramic membrane factory is in Anhui. The sales center is located in Suzhou, Jiangsu.

Special carbon graphite materials include medium grain graphite, fine grain graphite and ultrafine grain graphite.

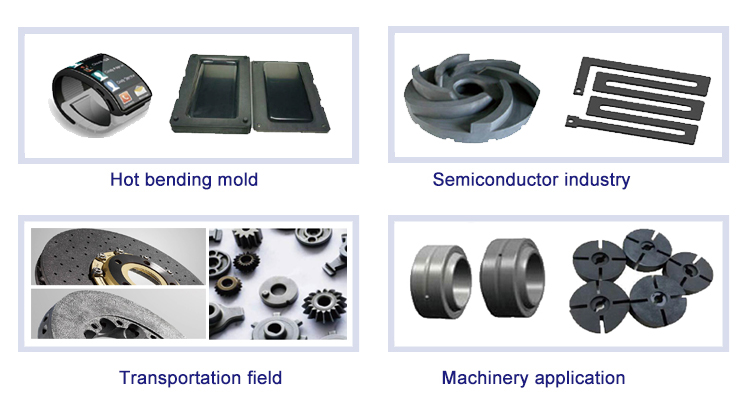

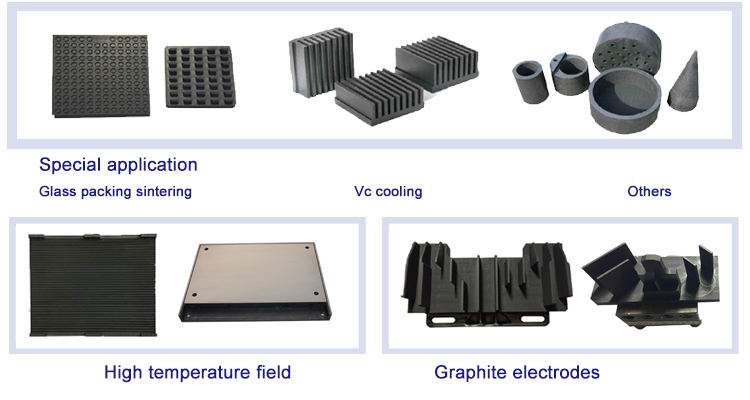

Specialty carbon products (carbon graphite products) will unleash the broad potential of carbon. They are high-performance products that support the development of key industries such as electronics, machinery, and metallurgy. They are also used in cutting-edge scientific fields such as the semiconductor, aviation and aerospace industries.

Characteristics of special graphite:

* High temperature resistance, melting point 3850±50℃, boiling point 4250.

* Low ash content and high purity to avoid contamination of your products.

* Graphite material is easily processed into any shape you like.

* High mechanical strength

* Good sliding performance

* High thermal conductivity

* High thermal shock and chemical resistance

* food safety

* Low wettability

* High corrosion resistance and oxidation resistance

* Good electrical conductivity

* High density and high mechanical strength

* Proper conductivity

Graphite material inspection report | ||||||||||||

Test items | Material | Test results) | Material | Test results) | Material | Test results) | ||||||

Density (g/cm3) | Isostatic pressure graphite | ≥1.85 | 0.8mm particles | ≥1.72 | 2-4mm particles | ≥1.60 | ||||||

Resistance (μΩ-m) | 11-13 days | ≤9 | ≤9 | |||||||||

Compressive strength (Mpa) | ≥107 | ≥30 | ≥25 | |||||||||

Bending strength (Mpa) | ≥40 | ≥16 | ≥13 | |||||||||

Thermal conductivity (W/mK) | 150 | 135 | 112 | |||||||||

Shore hardness | ≥64 | ≥40 | ≥25 | |||||||||

Particle size (mesh) | 1000 | 20 | 4-10 | |||||||||

Ash content(%) | ≤0.05 | ≤0.2 | ≤0.8 | |||||||||

Carbon content(%) | 99.995 | >99.5 | >99.2 | |||||||||

Comparative analysis of three materials | Through analysis and comparison of the three materials, the coarser the particle size, the lower the density. And the hardness, compression resistance, bending resistance and carbon content will all be reduced. | |||||||||||

product name | industry | application |

Crucibles, boats, dishes, etc. | Melting, refining and analysis | |

Dish, mold, ingot chassis, etc. | metallurgy | EDM graphite electrodes, semiconductor manufacturing, steel and non-ferrous metal manufacturing, continuous casting, metallurgical stamping machines |

Graphite roller, etc. | Steel plate furnace heat treatment | |

Conduits, slides, etc. | Aluminum forming | |

graphite tube | Masonry furnaces and other heat-resistant materials | |

graphite block | Masonry furnaces and other heat-resistant materials | |

Chemical Equipment | Heat exchangers, reaction towers, distillation towers, absorption equipment, centrifugal pumps, etc. | |

electrolytic plate | Salt solutions and baked molten salt electrolytes | |

electrolytic mercury | sodium chloride electrolyte | |

Anode grounded | Electrical anti-corrosion | |

Motor brush | electricity | Commutator, slip ring |

Current collector | Skates, slides, trolleys | |

Current collector | switches, relays | |

mercury ferries and tubes | electronic product | Anode, grid, repeller, ignition electrode and anode and grid of mercury rectifier |

Graphite bearings | mechanical | High temperature resistant sliding bearings |

sealing element | Seals, stuffing box seals, stuffing seals | |

product elements | Aircraft and vehicle braking | |

nuclear graphite | nuclear power | Deceleration materials, reflective materials, shielding materials, nuclear fuel, support devices, etc. |

Quality policy

This policy aims to adhere to the highest requirement of "quality first" by initiating updated quality management, and ultimately achieve quality projects to meet customer needs.

Quality goal

Strictly abide by quality control procedures, increase the prevention of common quality problems, provide customers with products that fully comply with relevant contracts and standards, ensure the effective operation of quality assurance and quality control systems, achieve zero quality accident rate and achieve good engineering construction quality.

Quality assurance system and functions

Establish quality assurance and effective quality control systems before construction to ensure the achievement of construction quality objectives.

Job responsibilities

Project Manager Responsibilities

Dasen has a R&D team2 pH. D.lead over20High-end R&D technicians.Dasen also has complete management processes and advanced development tools.

ISO9001-2015, ISO14001-2015, IATF16949-2016, UL

It has obtained more than 30 invention patents and utility model patents, and won honors such as "Technological Innovation Enterprise", "Jiangxi Province Special New Enterprise", and "National High-tech Enterprise".

As heaven moves forward, a gentleman must constantly strive to improve himself. DSN will strive to forge ahead and create greater glories.

FAQ

Q1. Can you introduce your main products?

certainly. We mainly produce thermally conductive graphite sheets, thermally conductive silicone sheets, and structural ceramics. For graphite specialty products, we can provide custom shapes based on our customers' specific needs. Materials include all grades of extruded/molded/isostatically pressed graphite.

Q2. What is your MOQ?

1 piece (graphite block/boat/plate/rod/round).

Q3. Can you provide free samples?

Yes, usually we can provide small product samples FOC without paying the express fee.

However, if the sample is expensive, such as large size, Dasen must charge the basic cost of the sample.

Q4. Do you accept OEM or ODM orders?

Yes, we do.

Q5. How about your delivery time?

Normally 15 to 30 days after payment, 7-10 days if we have raw materials in stock.

Q6. Do you test your goods before delivery?

Yes, we do testing before delivery.

Q7. How do you maintain long-term business relationships?

1. Good quality and competitive price to ensure mutual benefit;

2. Quick reply and sincere service.

Related Products

-

High strength and high purity thermally conductive isostatic graphite mold continuous casting mold

Product Description High-strength thermally conductive isostatic graphite mold for continuous casting Graphite products have the characteristics of low resistance, good electrical and thermal conductivity, high oxidation resistance, strong resistance to thermal shock and mechanical shock, high...... -

High quality, reasonably priced graphite nozzles and graphite molds

Bulk density (g/cm3): 1.68-1.85g/cubic centimeter Bulk density: 1.60--1.90g/cm3 Ash content: 0.3% Compressive strength: 45-135Mpa Compressive strength: 65 MPa Packaging details: Graphite is packed in sturdy standard wooden boxes or cartons Place of origin: Inner Mongolia, China technology:...... -

MZ Made in China Graphite Products Graphite Rocket Nozzles for the Aviation Industry

Resistance (μΩ.m): 4.5-12 Conductivity: Good thermal and electrical conductivity Chemical characteristics: Resistant to chemical attack Compressive strength: 60-120 type: Graphite mold Craftsmanship: Easy to process and good machining performance Porosity(%): 18-25th application: Mechanical...... -

Customized gold melting mold high purity casting carbon graphite ingot mold

Compressive strength: 65-135Mpa application: Casting processing, foundry industry technology: sintering mold product name: Graphite ingot mold Place of origin: Henan Province, China (Mainland),Henan Province, China port: Qingdao/Tianjin/Shanghai raw material: High purity graphite material Minimum...... -

Factory direct sales customized glass blowing graphite mold

brand: Jincheng Compressive strength: 30-150MPa density: 1.85 g/cm3 Material: High purity high density graphite Bulk density (g/cm3): 1.62-1.85g/cubic centimeter Supply capacity: 1000 tons per month color: dark grey pack: wooden box technology: Compression molding Key words: Graphite plate for...... -

High Quality Custom Carbon Graphite Ingot Crucible Box Mold for Melting Gold and Silver

port: Qingdao Port Porosity(%): 8-13% Key words: Graphite box Origin: Henan, China payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram color: Black size: Support customization Material: High-purity graphite material Resistance (μΩ.m): 5-20uΩm Ash content: 0.1% max model: KY06 thickness:...... -

China Manufacturer Custom Artificial Carbon Graphite Mold

Resistance (μΩ.m): 9~12 microohms.m Bulk density (g/cm3): 1.68-1.85 g/cm3 port: Qingdao laboratory: Special graphite testing laboratory. usable product name: Artificial graphite mold payment terms: L/C, Western Union, T/T Size and shape: customized product Compressive strength: 50~85Mpa or more...... -

graphite casting mold with gold silver ingot

Packaging Details: wooden box, wooden bag model: MZ15 brand: muzi Resistance (μΩ.m): 7.0μΩ*m Porosity(%): 11% application: metallurgy payment terms: L/C, D/P, D/P, T/T Package preview: Origin: Inner Mongolia, China Bulk density (g/cm3): 1.85 g/cm3 Compressive strength: 62Mpa technology: Sintering...... -

High pure graphite mold metal rod

Porosity(%): 11% Packaging Details: wooden box, wooden bag Compressive strength: 62Mpa brand: muzi payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram application: metallurgy Bulk density (g/cm3): 1.85 g/cm3 Resistance (μΩ.m): 7.0μΩ*m Origin: Inner Mongolia, China technology: Sintering mold.... -

Graphite molds for various glass

Origin: Shandong China Compressive strength: 30-150 MPa Ash content: 0.03 - 0.3% Packaging Details: Graphite molds for glass application carton or wooden case work: high purity carbon Bending strength: 24-36Mpa Material: High purity graphite payment terms: L/C, T/T Application one: Non-ferrous......