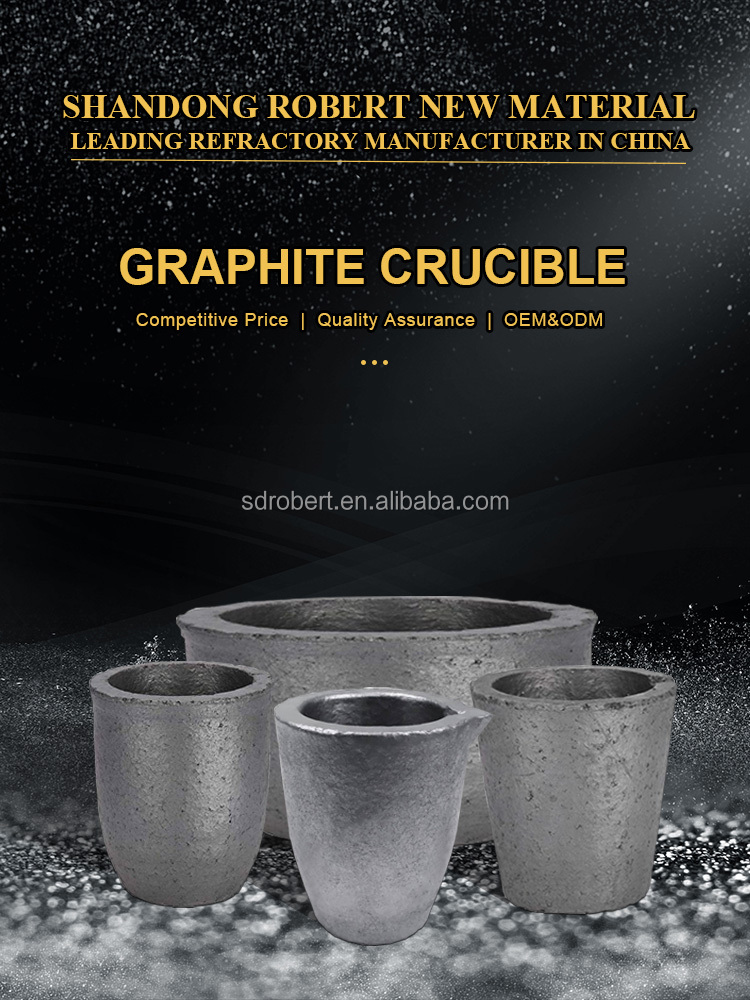

Acid-resistant silicon carbide graphite crucible graphite casting silicon carbide crucible silicon carbide graphite crucible

- $2.00 / >=5 pieces

- 5 pieces

- Shandong Robert New Material Co., Ltd.

- Shandong, China

- Ms Yan Zhang

Product Detail

| port: | Qingdao/Shanghai | color: | Black |

| application: | Chemical metallurgy | work: | silicon carbide |

| Carbon content: | ≥41.46% | brand: | Robert |

| Porosity: | ≤32% | model: | Ordinary/with spout/U-shaped crucible |

| sample: | usable | Place of origin: | Shandong Province, China |

| Silicon carbide content: | ≥24% | Package preview: | |

| size: | According to drawings or customer requirements | Refractory materials: | ≥1635℃ |

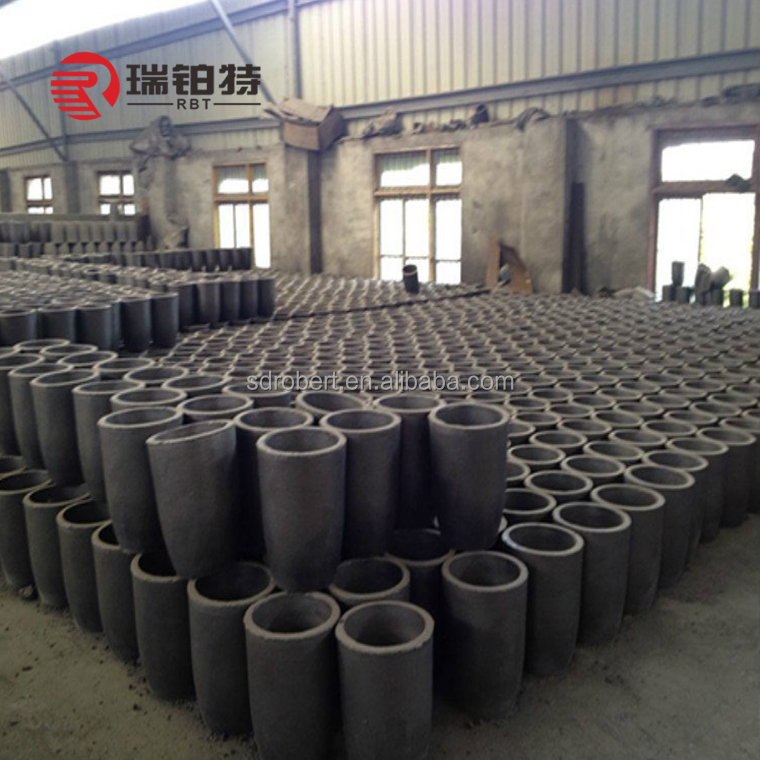

| Top diameter: | According to drawings or customer requirements | Supply capacity: | 60 tons per month |

| Bulk density: | ≥1.71g/cm3 | Bottom diameter: | According to drawings or customer requirements |

| payment terms: | L/C, Western Union, T/T, MoneyGram | Customs code: | 69031000 |

| type: | refractory | high: | According to drawings or customer requirements |

| Classification: | Silicon carbide/clay combined/pure graphite crucible |

product name | Graphite crucible |

describe | Graphite crucible, also known as molten copper ladle, molten copper, etc., refers to a type of crucible made of graphite, clay, silica, and wax stone as raw materials. |

Classification | Silicon carbide/clay bound/pure |

Main ingredients | Graphite, silicon carbide, silica, refractory clay, bitumen and tar |

size | Regular sizes, special sizes and OEM services are also available! |

shape | Conventional crucibles, nozzle crucibles, U-shaped crucibles (oval crucibles), and OEM services are provided! |

feature | High temperature resistance; strong thermal conductivity; good corrosion resistance; long service life |

Regular CLucipur

Spray Crucible

Spray Crucible

U-shaped crucible (oval crucible)

Crucible combination

Crucible combination

Crucible combination

Crucible combination

Performance index/unit | Index value | Index value | Index value |

Bulk density g/cm3 | 1.82 | 1.85 | 1.90 |

ResistivityμΩm | 11~13 | 11~13 | 8~9 |

Thermal conductivity (100℃)W/mk | 110~120 | 100~120 | 130~140 |

Thermal expansion coefficient (Room temperature-600℃)10-6/℃ | 5.8 | 5.9 | 4.8 |

Shore hardness HSD | 65 | 68 | 53 |

Bending strengthMpa | 51 | 62 | 55 |

Compressive strengthMpa | 115 | 135 | 95 |

Elastic modulus Gpa | 12 | 12 | 12 |

Porosity% | 12 | 12 | 11 |

Ash PPM | 500 | 500 | 500 |

Purified Ash PPM | 50 | 50 | 50 |

Particle size μm | 8~10 | 7 | 8~10 |

1. During high-temperature use, it has a small thermal expansion coefficient, has certain adaptability, and can quickly cool and heat. It has strong corrosion resistance to acidic and alkaline solutions, has excellent chemical stability, and does not participate in any chemical reactions during the smelting process.

2. The inner wall of the graphite crucible is smooth, and the molten metal is not easy to leak and adhere to the inner wall of the crucible, so that the molten metal has good fluidity and castability, and is suitable for various mold castings.

3. Because graphite crucible has the above excellent characteristics, soMainly used for smelting copper, brass, gold, silver, zinc, lead and other non-ferrous metals and their alloys.

VIEW MORE

Related Products

-

Silicon carbide graphite crucible with nozzle manufacturer aluminum scrap casting

Product Description advantage: The silicon carbide graphite crucible produced by our company has the following characteristics: 1. Higher thermal conductivity: shorten melting time and save energy; 2. Higher strength: isostatic pressing, no defects in the internal structure, and high physical...... -

Melting Furnace Graphite Crucible Metal Melting Electromechanical Melting High Temperature Resistant Melting Metal Melting

Company Profile Graphite solution expert to solve problems——Shandong Guanzhi New Material Technology Co., Ltd. Shandong Guanzhi New Material Technology Co., Ltd. has continued to grow and develop after twenty years of hard work. The product coverage is wide and the domestic marketing network has...... -

Customized high temperature resistant graphite melting crucible for loading molten metal

Place of origin: Guangdong, China payment terms: T/T, Trade Assurance Supply capacity: 200 pieces per month Top diameter: Customized melting crucible top diameter Bottom diameter: Customized melting crucible bottom diameter application: Loading molten metal while melting Applications of custom...... -

Laboratory Analysis Graphite Crucible of Thermal Resistance Furnace

Compressive strength: 55-135MPa Ash: ≤0.15% or less type: high strength Maximum ℃: 3000℃ work: quartz Bottom diameter: as requested feature: Wide range of applications product name: Laboratory analysis thermal resistance furnace graphite crucible brand: the best Package preview: Grain size: 8-18...... -

High quality silicon carbide graphite crucible for melting non-ferrous metals

Supply capacity: 3000 pieces per month Material: SiC silicon carbide model: 8# type: isostatic pressing Origin: Shandong Province, China Molten metal: Zinc, zinc oxide, copper, gold, silver high: 120 mm Packaging Details: wooden box pack: wooden box Bottom diameter: 135 mm Advantage: High...... -

High quality factory price 50kg 250kg silicon carbide crucible silicon carbide sagger melting graphite crucible

work: High purity color: dark grey type: refractory brand: Rongsheng high: According to customer requirements usage: Melted Aluminum, Copper Original content: 98% or customized model: RS-SC-001 density: 1.9-2.1 g/cm3 feature: long lasting product name: Graphite crucible for melting Top Diameter:...... -

Graphite crucible for gold melting Large size silicon carbide graphite crucible for aluminum melting Silicon carbide graphite casting crucible

brand: Robert Operating temperature: 1800 degrees Celsius product name: Graphite crucible set type: refractory Bottom diameter: According to customer requirements usage: Melting aluminum, copper, iron, etc. Top Diameter: According to customer requirements Silicon carbide %: 98% or customized...... -

High quality graphite crucible for melting

high: custom made model: TE work: High purity application: molten metal brand: TE port: Beijing, Tianjin, Shanghai, Qingdao Top Diameter: 40-1000mm Origin: Beijing China Packaging Details: Carton, wooden box type: high strength Supply capacity: 20,000 tons/year payment terms: L/C, D/A, D/P, T/T,...... -

40g-9kg factory price cheaper sale cost graphite ingot mold for casting

color: black gray high: custom mm type: refractory payment terms: Western Union, T/T, Trade Assurance usage: aluminum silver gold copper melting Supply capacity: 2000 pieces per month Carbon content: 99.98% port: Guangzhou Port MOQ: 10 Package preview: Top Diameter: custom mm Bulk density:...... -

Factory price high purity anti-oxidation 0.5kg mini graphite crucible melting pot

work: High purity Bottom diameter: custom made Packaging Details: Packing: plastic bag + carton + pallet (carton size: 20cm*20cm*15cm) according to customer requirements Package preview: model: MS#CR001, as-591 Top Diameter: custom made application: metal smelting, smelting metal Supply capacity:......