High tenacity high modulus original white 12mm UHMWPE chopped chopped fiber

- $14.99 / >=20 kilograms

- 20 kilograms

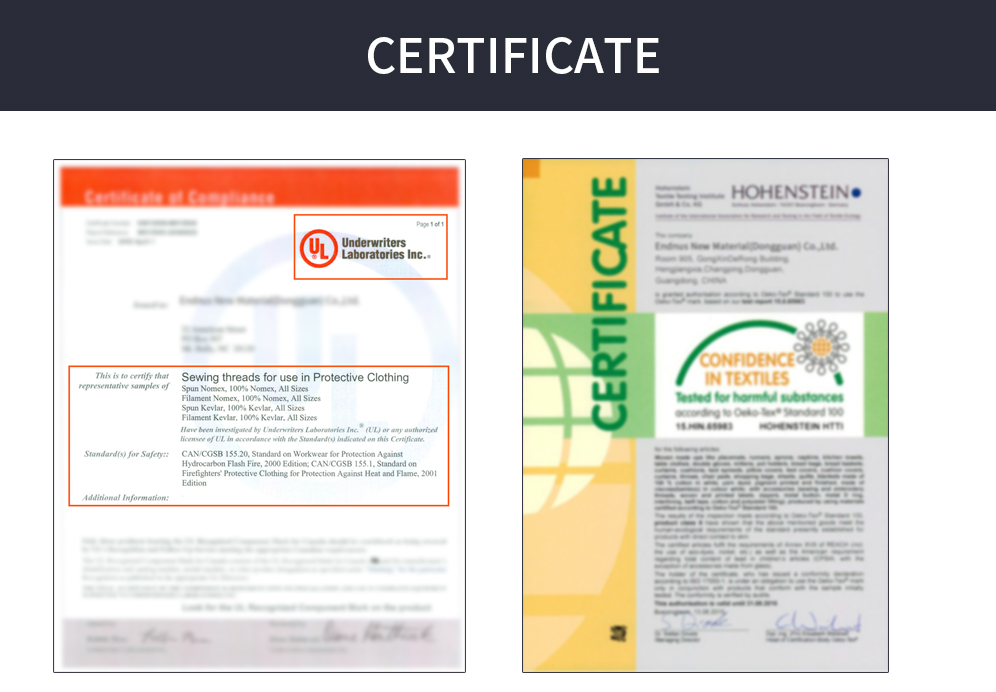

- Endnus New Material (Dongguan) Co., Ltd.

- Guangdong, China

- Mr Ethan Jiang

Product Detail

| Melting point: | 135~145℃ | Material: | UHMWPE fiber |

| brand: | terminal | anti-UV: | durable |

| Resist: | >10^14Ω | model: | HPFI-1221 |

| elongation: | 3.5% | Packaging Details: | 10kg per bag. |

| port: | Shenzhen, Guangzhou | Supply capacity: | 10000 kg per week |

| Fineness: | two-dimensional | place of origin; place of origin: | Guangdong, China |

| Thermal conductivity (along fiber axis): | 20w/mk | length: | 12mm |

| toughness: | 35cN/tex | payment terms: | L/C,Western Union,T/T,MoneyGram,Credit Card |

| Modulus: | 1000-1350g/d | feature: | bulletproof, anti-cut, light weight, anti-ultraviolet, anti-corrosion, anti-impact, high-strength, anti-radiation, wear-resistant |

| Hot water shrinkage: | <1% | color: | white |

UHMWPE staple fiber, referred to as UHMWPE staple fiber, is cut from ultra-high molecular weight polyethylene filament fiber.

Mainly used in engineering concrete reinforcement, textile, laboratory and other fields.

Chopped fibers can be called chopped fibers, which are generally disordered and are often used to improve the comprehensive properties of reinforcing materials. Adding short fibers to concrete can prevent cracking and enhance toughness.

Conventional chopped lengths are 3mm, 6mm, 9mm, 12mm.

Crimp cut lengths are 31mm, 38mm, 51mm, 55mm, 76mm.

Application of Fiber Reinforced Concrete Composites

The compressive strength, tensile strength and flexural strength of concrete are greatly improved after adding appropriate amount of UHMWPE short fibers.

High strength and high modulus

The matrix strength of fiber-based concrete is much higher than that of ordinary concrete. The mechanical properties of the traditional concrete matrix can be further improved by adding some traditional fibers into the concrete structure, so this technology has been more and more widely studied and applied.

Related Products

-

High strength and high modulus Dyneema fabric

Product Description High strength and high modulus Dyneema fabric Style: One-way Weight per square meter: 120GSM, 140GSM, 160GSM, Width: 1.6m and 1.2m Fiber strength: 35 g/d Fiber density: 600D Product type: UD fabric Thread strength/breaking strength 38g/day width: 160cm, or customized. Fabric...... -

Customized 30-1500m width wear resistant fabric 130gsm 200gsm 240gsm 300gsm UHMWPE woven fabric high strength UHMWPE fabric

type: Woven fabrics Function: Anti-cut/anti-bite/wear-resistant/ Gross weight per piece: 1.000 kg Color: 1000D model: SWT-SLUR00052 figure: Lightweight/High strength/Cut resistant Brand Name: Sovetel toughness: High strength Wide: 30-1500 meters Sales Unit: Single item Material: UHMWPE fiber +...... -

Cut-resistant dog UHMWPE fabric 5-grade cut-resistant wear-resistant puncture-resistant knitted wear-resistant UHMWPE fabric

toughness: High strength density: 330 g/m², 550 g/m² Material: UHMWPE fiber + glass fiber + polyester fiber, UHMWPE fiber figure: Lightweight/High strength/Cut resistant Function: Anti-cut/anti-bite/wear-resistant/ process: knitting Origin: Guangdong, China feature: Lightweight, UV-resistant,...... -

1mm - 6mm UHMWPE core with polyester sheathed rope

Material: WHMWPE core with polyester jacket, UHMWPE fiber payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram Stranded wire: 16 shares brand: auspicious Place of origin: Jiangsu, China color: Gray, green, yellow, red, blue, black, etc. For people: unisex Packaging details: Using standard...... -

120gsm 130gsm 150gsm 160gsm 800d High Strength White Fiber Hppe Ud Uhmwpe Sheet 0.1mm Uhmwpe Soft Armor Fabric

usage: Personal safety density: 130-160gsm feature: Notch-proof, light-weight, UV-resistant, corrosion-resistant, impact-resistant, high-strength, radiation-resistant, abrasion-resistant Package: carton size: custom Serve: Accept OEM ODM brand: Influence port: Ningbo, Shanghai, Tianjin, Shenzhen...... -

2023 Ultralight Knife Resistant Aramid Fabric Uhmwpe Woven Fabric Roller Tents Uhmwpe Fabric 2022

size: custom Supply capacity: 3000 tons per month brand: Influence usage: Personal safety application: vest jacket suit backpack ID: Accept custom logo density: 130-160gsm toughness: High payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram Packaging Details: carton Serve: Accept OEM ODM...... -

High Performance Uhmwpe Yarns Dyneemas Apparel Uhmwpe Knitting Fabrics Woven Cut Resistant Uhmwpe Fabrics

model: UHMWPE Fabric-1 elongation: 200 days 400 days 1000 days width: 150cm Supply capacity: 3000 tons per month payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram Fineness: 100-2400D Function: impact resistance Packaging Details: carton feature: Cut resistance, light weight, UV...... -

Polyethylene Ballistic Lightweight Soft UHMWPE Ballistic UD Fabric

feature: Bulletproof, anti-cut, light weight, anti-ultraviolet, corrosion-resistant, impact-resistant, high-strength, radiation-resistant, wear-resistant color: bright white model: S-160/120/130gsm width: 162±2cm toughness: / appearance: Smooth Supply capacity: 10000 kg per month Fineness: /...... -

High quality UHMWPE fiber for UD cloth body armor

feature: Abrasion-resistant, impact-resistant, cut-resistant, UV-resistant, bullet-proof, corrosion-resistant, high strength, light weight, radiation-resistant Material: UHMWPE Fiber Package preview: model: QXL-1600D Supply capacity: 400 metric tons per month type: uhmwpe fiber for body armor...... -

Hound Cloth High Quality Aramid Fabric Men Clothing Tear Resistant 2022 Uhmwpe Cut Resistant Clothing Fabric

payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram Packaging Details: carton Supply capacity: 3000 tons per month application: Cut Resistant Fabric color: multiple colour Origin: Zhejiang, China expiration of pay: TT model: uhmwpe fabric-1 feature: Cut resistance, light weight, UV......