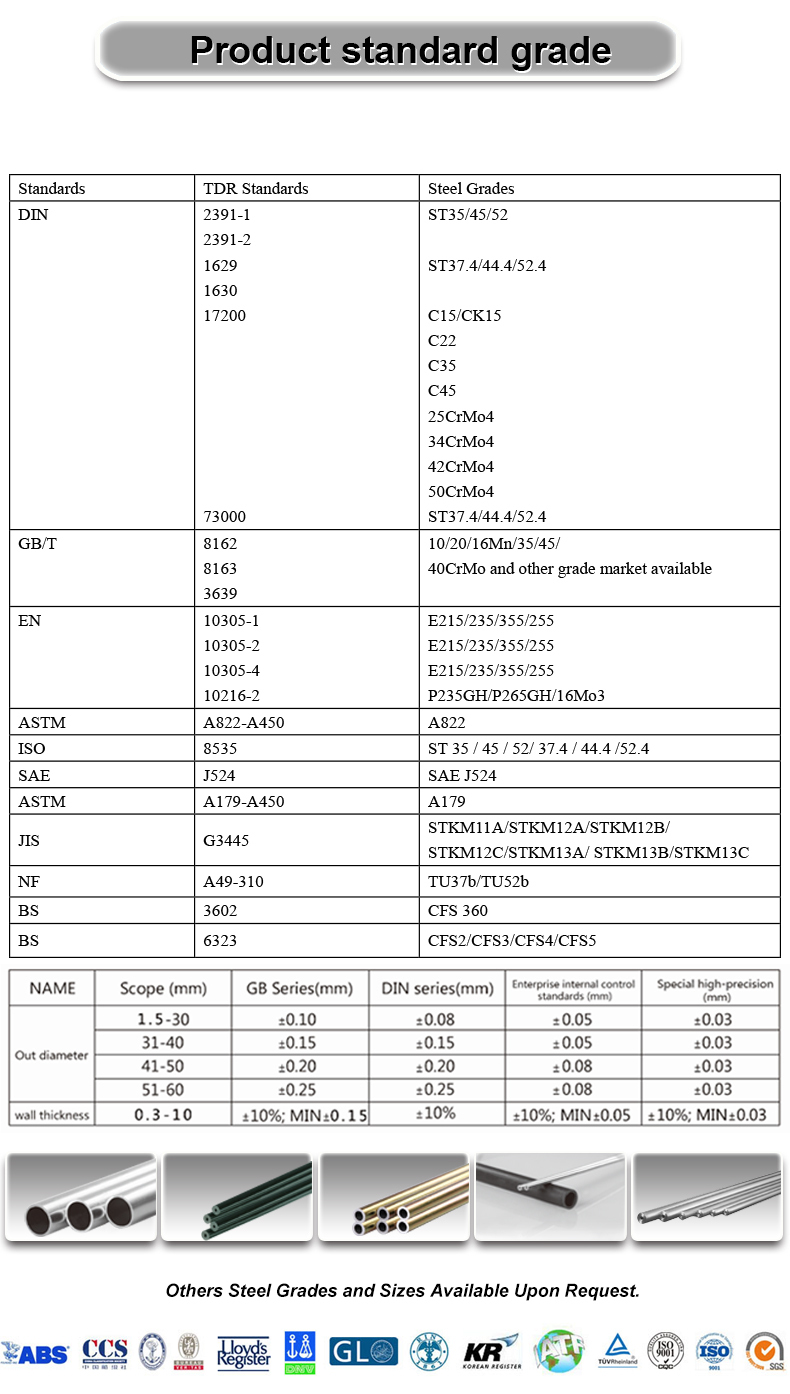

Small Diameter ASTM 4140 Thick Wall Seamless Alloy Round Steel Tube

-

$15.00 / 20 - 99 pieces

$12.00 / 100 - 199 pieces

$8.00 / >=200 pieces - 20 pieces

- Henan Danqiu International Trade Co., Ltd.

- Henan, China

- Mr yin

Product Detail

| Special tube: | thick wall tube | standard: | ASTM |

| Middle school or not: | non-secondary school | Section shape: | round |

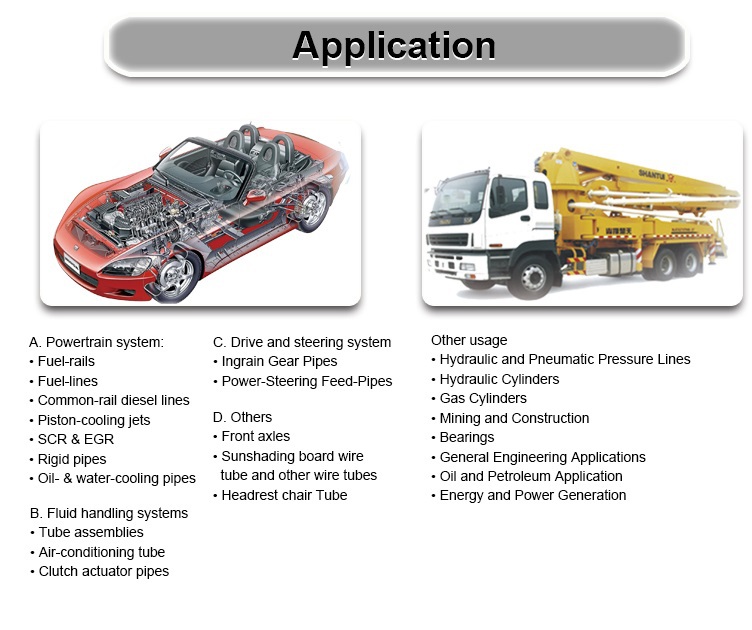

| Alloy or not: | Unalloyed | application: | Structural tubes, hydraulic tubes, air gun barrels, air gun barrel tubes and pipes |

| Outer diameter: | 1.5 - 60 mm, 1.5 - 60 mm | Steel grade: | C45, 4130, 4140, 30CrMo, 42CrMo, ST35, ST45, etc. |

| To oil or not to oil: | no fuel | delivery time: | within 7 days |

| Invoicing: | by actual weight | Origin: | Jiangsu, China |

| tolerant: | 0.02mm | Certificate: | ISO 9001 TS16949 |

| Certification: | TS16949 ISO9001 | Package preview: | |

| thickness: | 0.5 - 6mm | payment terms: | L/C, Western Union, T/T |

| Processing services: | to cut | Surface treatment: | black phosphating or galvanized |

| grade: | ST35-ST52 | length: | 60cm |

| technology: | cold drawn, cold drawn | brand: | Dan Qiu |

| delivery conditions: | BK, GBK, BKW, BKS or NBK | type: | seamless steel pipe |

Please contact us for the specific model and size, we will give you the best price

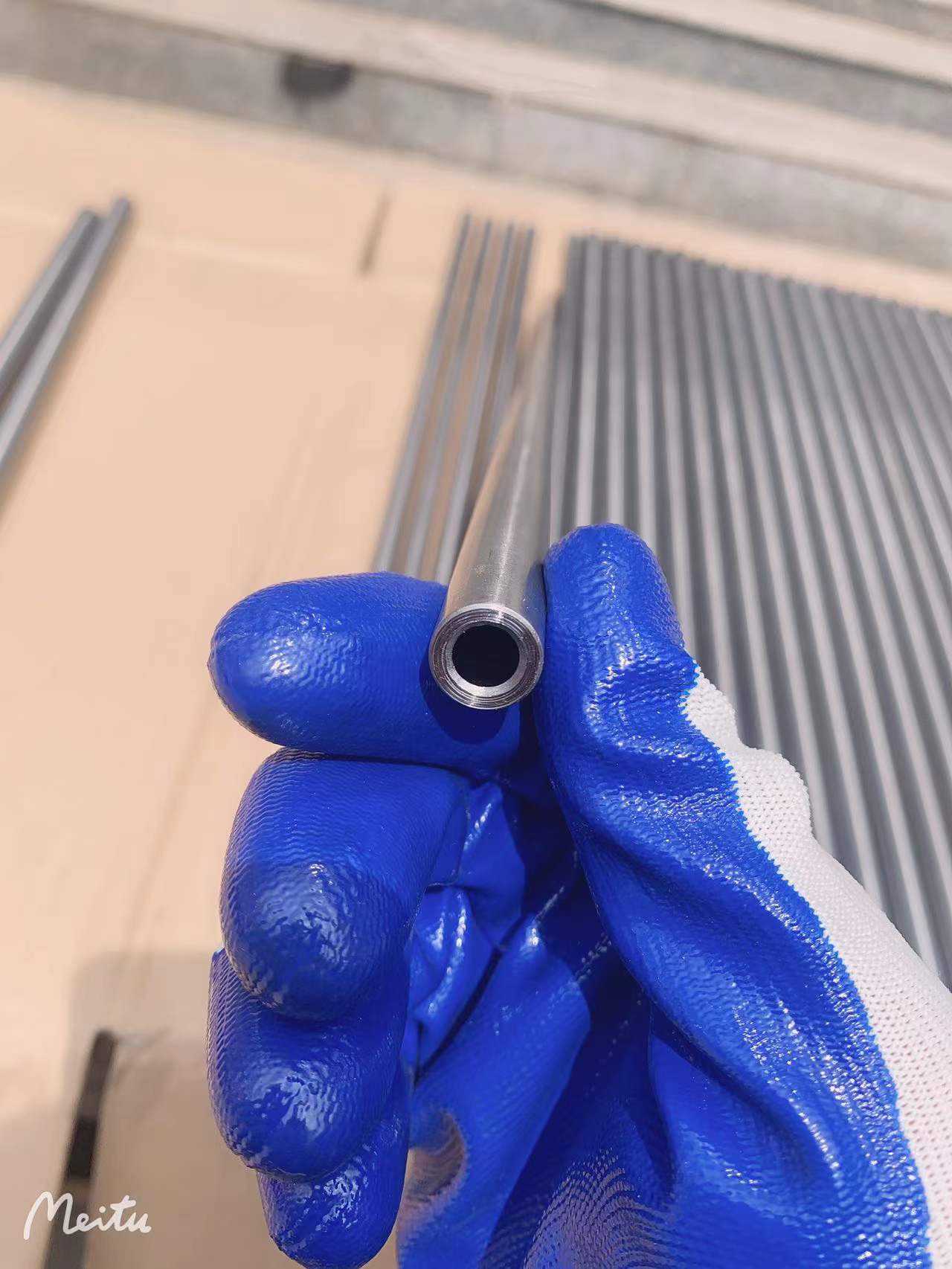

Main outer diameter 16mm and 12mm others also available

Pipe size can be designed according to customer requirements

Best hardness and processing ability

Common size

4.5 mm inner diameter 12 mm outer diameter

Inner diameter 5.5mm Outer diameter 12mm

6.03 mm inner diameter 12 mm outer diameter

7.03 mm inner diameter 12 mm outer diameter

8.03 mm inner diameter 12 mm outer diameter

4.5 mm inner diameter 16 mm outer diameter

5.4 mm inner diameter 16 mm outer diameter

5.45 mm inner diameter 16 mm outer diameter

5.5 mm inner diameter 16 mm outer diameter

5.6 mm inner diameter 16 mm outer diameter

5.8 mm inner diameter 16 mm outer diameter

6.03 mm inner diameter 16 mm outer diameter

6.25 mm inner diameter 16 mm outer diameter

6.3 mm inner diameter 16 mm outer diameter

6.35 mm inner diameter 16 mm outer diameter

6.5 mm inner diameter 16 mm outer diameter

6.8 mm inner diameter 16 mm outer diameter

7.03 mm inner diameter 16 mm outer diameter

8.03 mm inner diameter 16 mm outer diameter

8.5 mm inner diameter 16 mm outer diameter

8.6 mm inner diameter 16 mm outer diameter

9.03 mm inner diameter 16 mm outer diameter

10.03 mm inner diameter 16 mm outer diameter

12.03 mm inner diameter 16 mm outer diameter

Other according to customer requirements

ID tolerance can be controlled within +/-0.02

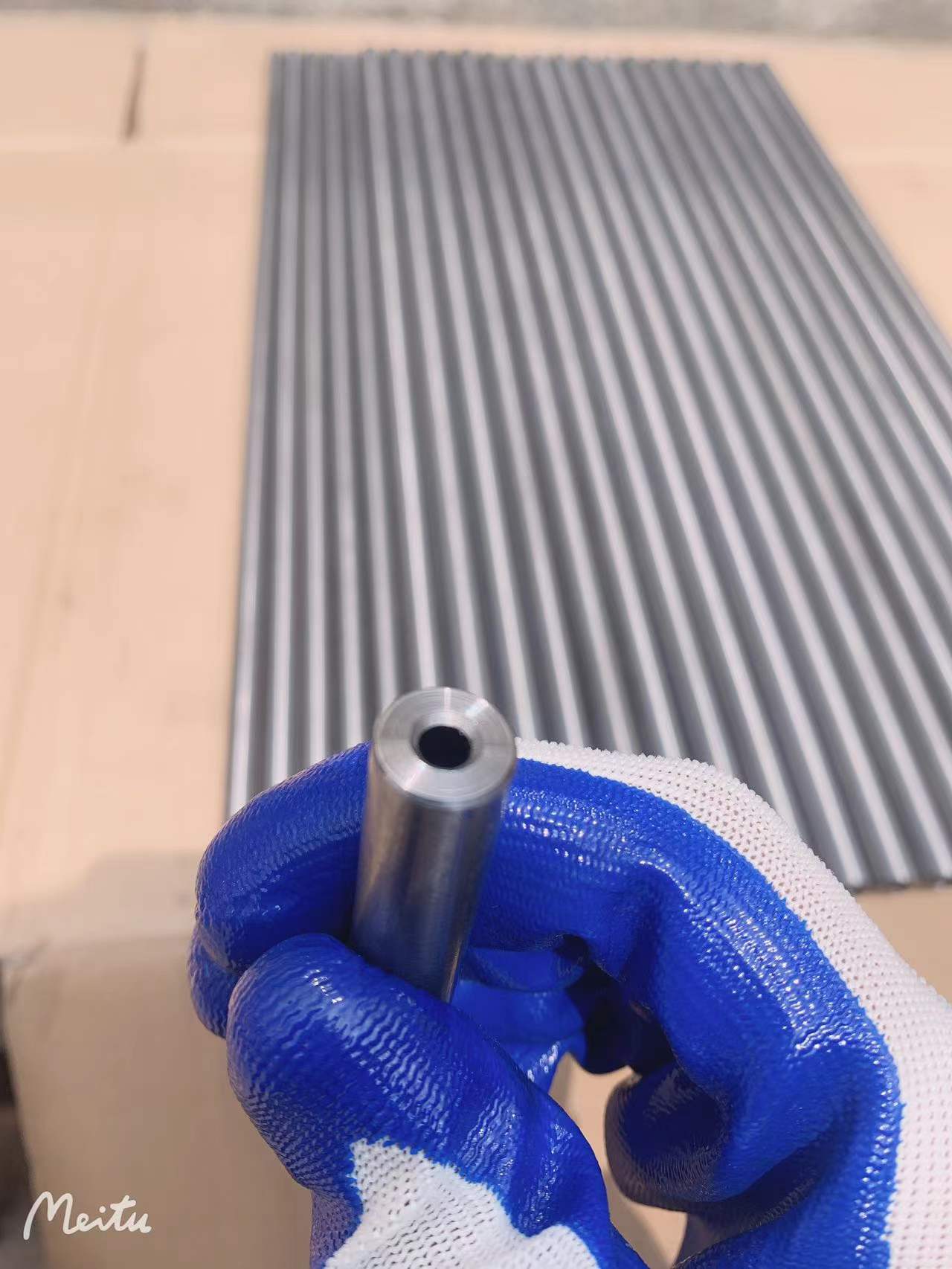

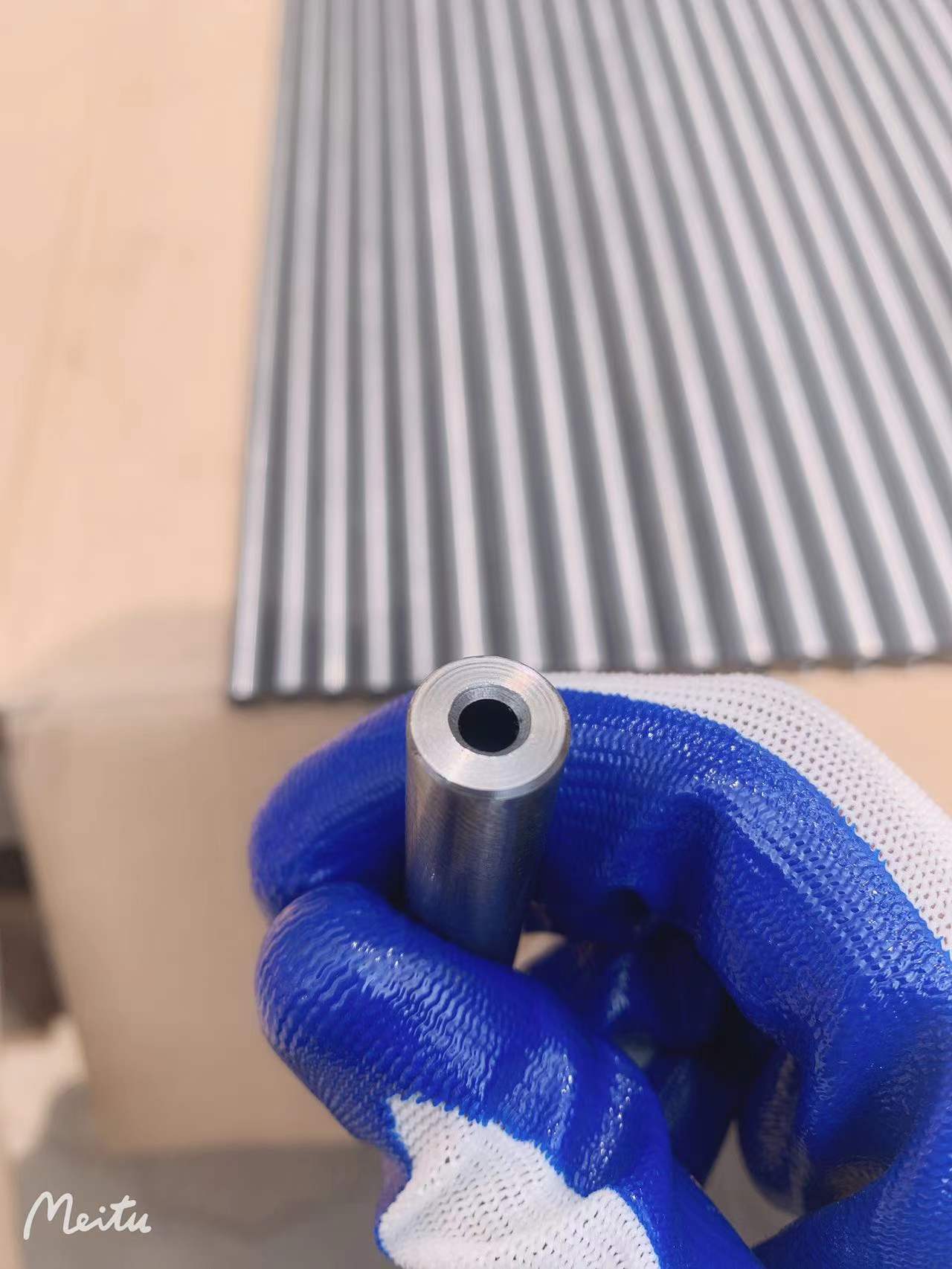

Shiny interior and exterior surfaces

Steel type: S45C, 4130, 4140, 30CrMo, 42CrMo, 42CrMo4, etc.

Good quality tubing consumes less buttons when grooving

special production process

Other sizes we manufacture:

Outer diameter: 1.5mm-60mm

Wall thickness: 0.3mm to 10mm

Certificate:

According to EN 10204 3.1

Test items: tensile strength, yield strength, elongation, flattening, flaring chemical analysis eddy current

100% testing, 100% dimension and surface inspection Other testing items can be arranged upon request

delivery conditions:

Tubes can be produced under the following delivery conditions:

BK (+C) Cold worked/hard (cold worked, drawn).

There is no heat treatment after the last cold forming process.

BKW (+LC) Cold Worked/Soft (Slightly Cold Worked)

After the final heat treatment, light finishing (cold drawing) is carried out.

BKS (+SR) Cold working/stress relief annealing.

After the final cold forming process, the tube is stress relieved annealed.

GBK (+A) annealed.

After the final cold forming process, the tube is annealed in a controlled atmosphere.

NBK (+N) normalization. (Main concern)

After the final cold forming process, the tube is annealed above the upper transformation point in a controlled atmosphere

Some related steel samples

|

National standard |

TOCT |

ASTM |

bachelor |

JIS |

NF |

industry standard |

|

10F |

1010 |

040A10 |

XC10 |

|||

|

10 |

10 |

10,101,012 |

045M10 |

S10C |

XC10 |

C10,CK10 |

|

20 |

20 |

1020 |

050A20 |

S20C |

XC18 |

C22,CK22 |

|

45 |

45 |

1045 |

080M46 |

S45C |

XC45 |

C45,CK45 |

|

30CrMo |

30XM |

4130 |

1717COS110 |

MCU 420 |

30CD4 |

|

|

42CrMo |

4140 |

708A42 |

|

42CD4 |

42CrMo4 |

|

|

708M40 |

||||||

|

35CrMo |

35XM |

4135 |

708A37 |

Microcontroller 3 |

35CD4 |

34CrMo4 |

Other grades are also available according to customer requirements and market conditions

surface treatment

1. Bare pipe (without coating): bright and smooth, surface roughness 0.2Ra Maximum for special requirements

2. Surface coating

A. Silver plating

B. Yellow galvanized

C. Olive green coating

Layer thickness: 8-20um, salt spray test: 48-150 hours

3. Black Phosphate

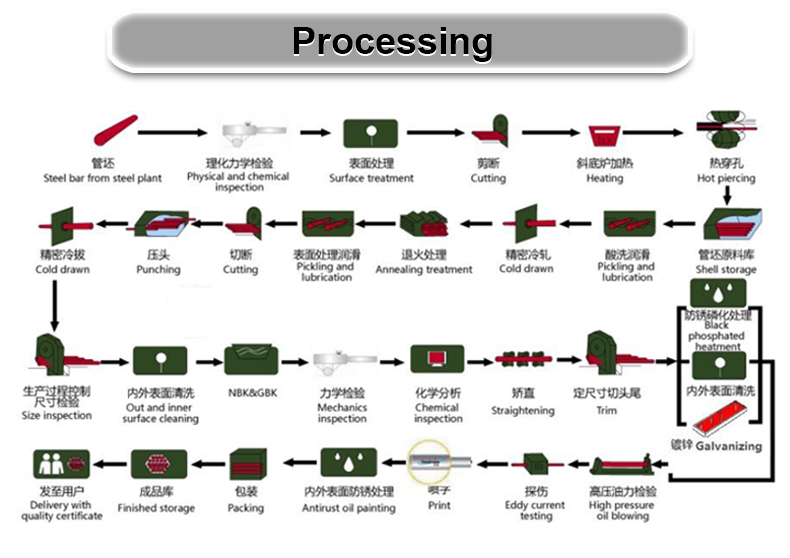

Steel mill bar → physical and chemical inspection → surface treatment → cutting → heating → hot piercing → shelling → pickling and lubrication → cold rolling → heat treatment → pickling and lubrication → cutting → punching → cold drawing → dimension inspection → internal and external surface cleaning → NBK Or GBK→mechanical test→chemical analysis

Anti-rust oil printing → printing → packaging → finished product storage → delivery with quality certificate

1. We use special technology and special skills in the pickling process to deal with the places where wrinkles and gaps are easy to form;

2. The process organization is strict, especially the technical requirements for annealing treatment are strict;

3. In terms of lubrication, we have adopted an internationally advanced treatment process to strictly control the surface quality of the product to prevent surface cracks.

Employees: 80 registered

Capital: RMB 8.2 million

Annual sales: about 600 million yuan

Monthly output: 400Ton

Plant area: about 7000 square meters

Production equipment:

Cold drawn wire

Two heat treatment lines

straight line

polisher

Cutting Machine

others

Hydraulic universal testing machine for testing tensile strength, yield point, flaring, flattening and elongation

C, S, Si, Mn, P analysis equipment

Hardness testing machine

Metallographic Analyzer

Eddy current ultrasonic nondestructive testing machine

visual inspection table

100% eddy current testing

100% dimensional and surface inspection

Related Products

-

Chrome alloy pipe En 19c 20crmo 42crmo thick wall seamless steel pipe

product name: Seamless steel pipe payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram, XT brand: benzalkonium usage: Oil, gas and sewage transportation standard: ASTM, EN, DIN, GB To oil or not to oil: No oiling bill: According to theoretical weight surface: BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D.... -

Seamless steel pipe inventory: Chinese professional manufacturer has large inventory supply and standing inventory of 50,000 tons

Whether alloy: non-alloy Special pipes: API pipe Material: A53, ST33, A283, A135, ST37, A53, A106, ST35, A179 Cross-sectional shape: round brand: Hongtai thickness: 2mm~15mm, 2mm~15mm external: 8~100mm payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram Processing services: Welding,...... -

TORICH Din 17175 St45.8 STKM11A SAE 4130 Internal Polished Honed Steel Tube Spring Seamless Steel Tube for Oil and Gas Transmission

technology: cold drawn Surface treatment: anti-rust oil grade: C20, ST52, SAE1026, CK45, 25MN port: Qingdao, Tianjin Supply capacity: 30000 tons per month tolerant: ±1% application: Hydraulic pipes, hydraulic cylinders, hydraulic pipes heat treatment: Black+S To oil or not to oil: Shop primer and...... -

DIN2391scm Precision Seamless Steel Pipe/Automotive Pipe/Steel Pipe

standard: ASTM, ANSI A213M-2001, DIN, DIN 2391, DIN 17175, DIN EN 10305, GB, GB/T 8163-1999, GB/T 8162-1999, GB/T 3639-2000, GB/T8162, Gb/t8163, GB/T3639, JIS, JIS G3445-2006 Origin: Jiangsu, China Steel pipe length: Customer requirements for steel pipes Certification: ISO9001:2008 Steel pipe...... -

Factory direct black square rectangular steel pipe and pipe seamless metal carbon square steel pipe making machine

standard: ASTM AISI GB JIS EN DIN Certificate: API, CE, Bsi, RoHS, SNI, BIS, SASO, PVOC, SONCAP, SABS, sirm, tisi, KS, JIS, GS, ISO9001 shape: round tube payment terms: L/CT/T (30% deposit) To oil or not to oil: not oiled Origin: Shandong Province, China tolerant: ±1% Section shape: square End...... -

Wholesale Hot Dip Galvanized Seamless Galvanized Round Steel Pipe ASTM A106 Sch 40 ERW GI Iron Pipe

To oil or not to oil: not oiled Processing services: Welding, punching, cutting, bending, decoiling sample: free sample shape: round tube length: 12M, 6m, 6.4M standard: bs, GB, ASTM, JIS, DIN payment terms: L/C, Western Union, T/T, MoneyGram delivery time: 8-14 days Surface treatment: galvanized,..... -

Widely used ASTM JIS DIN 2391 PART 2 ST30Si ST30Al ST35 ST45 ST52 Precision seamless steel tube

delivery time: within 7 days product name: seamless steel pipe Material: ASTM/AISI/SGCC/CGCC/TDC51DZM/TDC52DTS350GD/TS550GD/DX51D+Z Q195-q345 Invoicing: by actual weight Surface treatment: Cold Rolled/Hot Rolled Package preview: Packaging Details: According to customer needs brand: Mannesmann...... -

Factory direct sale price favorable carbon seamless steel pipe ASTM A106b cold rolled precision steel pipe

Section shape: round Surface treatment: Hot Rolled/Cold Rolled Material: ASTM/AISI/SGCC/CGCC/TDC51DZM/TDC52DTS350GD/TS550GD/DX51D+Z Q195-q345 MOQ: 1 ton Key words: Precision steel pipe/pipe Processing services: Welding, punching, cutting, bending, decoiling tolerant: ±1% Origin: Shandong China...... -

Precision Use Carbon Steel Small Diameter Steel Pipe Size Outer Diameter (OD) 6mm Tube Inner Diameter 4.4mm, 5.4mm, 5.5mm, 6.3mm, 6.35mm, 6.8mm

brand: Dan Qiu standard: ASTM type: seamless steel pipe Package preview: delivery conditions: BK, GBK, BKW, BKS or NBK Origin: Jiangsu, China Outer diameter: 1.5 - 60 mm, 1.5 - 60 mm thickness: 0.5 - 6 mm payment terms: L/C, Western Union, T/T length: 60cm Middle school or not: non-secondary school.... -

ASTM4130 Cr-Mo Steel Bicycle Frame Carbon Steel Pipe Seamless Pipe

Packaging Details: 1. Steel pipe wrapped in waterproof paper 2. Steel pipe with several pieces of linen 3. Steel pipe cover 4. Steel pipe wooden box Outer diameter: 3 - 80 mm payment terms: L/C,Western Union,D/P,D/A,T/T,MoneyGram,Steel Paypal Steel pipe shape: Round steel pipe technology: cold......