Wholesale High Quality Injection Plastic Mold Plastic Parts Auto Lamp ABS PC Mold Manufacturer

-

$1.80 / 500 - 999 pieces

$1.60 / 1000 - 1999 pieces

$1.50 / >=2000 pieces - 500 pieces

- Dongguan Jiachenxing Electronic&technology Co.,ltd.

- Guangdong, China

- Ms Lucy Yuan

Product Detail

| exit: | USA, Germany, Japan | Packaging Details: | PE bag+cardboard+carton |

| port: | Shenzhen | color: | Black |

| capacity: | 3000 sets/day | Surface treatment: | Polish + Die Texture |

| Processing services: | forming | payment terms: | L/C, T/T |

| raw material: | ABS,ABS+PC,PC | Plastic model type: | injection |

| Processing Equipment: | Injection machine | brand: | Jin Chengxing |

| Package preview: | model: | P-015 | |

| process: | injection | Origin: | Guangdong, China |

| scope: | Car doors, lights, center consoles, decorative panels, etc. | Mold material: | S136H,NAK80 |

| product name: | Automobile Plastic Parts | Supply capacity: | 2000 pieces per day |

Product Description

category | plastic |

raw material | ABS, ABS+PC, PC |

Processing Equipment | Injection machine |

mold material | S136H, NAK80 |

surface treatment | Polish + Die Texture |

process | injection |

scope | Car doors, lights, center consoles, decorative panels, etc. |

capacity | 3000 sets/day |

exit | USA, Germany, Japan |

Company Profile

Dongguan Jiachenxing Electronics Co., Ltd. is located in Fenggang Town, Dongguan City, with convenient transportation and active economy. Its production and processing plant was established in 2004, and the company currently employs more than 300 people. After more than ten years of development and growth, it has become a medium-sized processing enterprise with mold development, plastic molding, metal stamping molding, plastic hardware surface treatment as its main business, and the assembly of electronic products, electric toys and other finished products as a new development direction.

The factory covers an area of more than 20,000 square meters, with 29 sets of 80T~1200T injection molding machines, more than 10 sets of plastic extrusion molding machines, 12 sets of metal stamping forming equipment, 10,000-level dust-free manual UV spraying line, 10,000-level dust-proof - bottom-free Two paint spraying lines, one dust-free UV automatic spraying line, two screen printing pad printing lines; more than 20 sets of mold development equipment CNC, spark machine, engraving machine, grinding machine, milling machine, lathe, etc.; and two finished product assembly lines.

With advanced production equipment, sophisticated testing equipment, perfect design, development, production and testing capabilities, and a high-quality, high-level elite team, we have won the cooperation and support of friends from all walks of life. It can provide customers with one-stop service, solve customized needs of customers, shorten the development cycle, and create opportunities for customers.

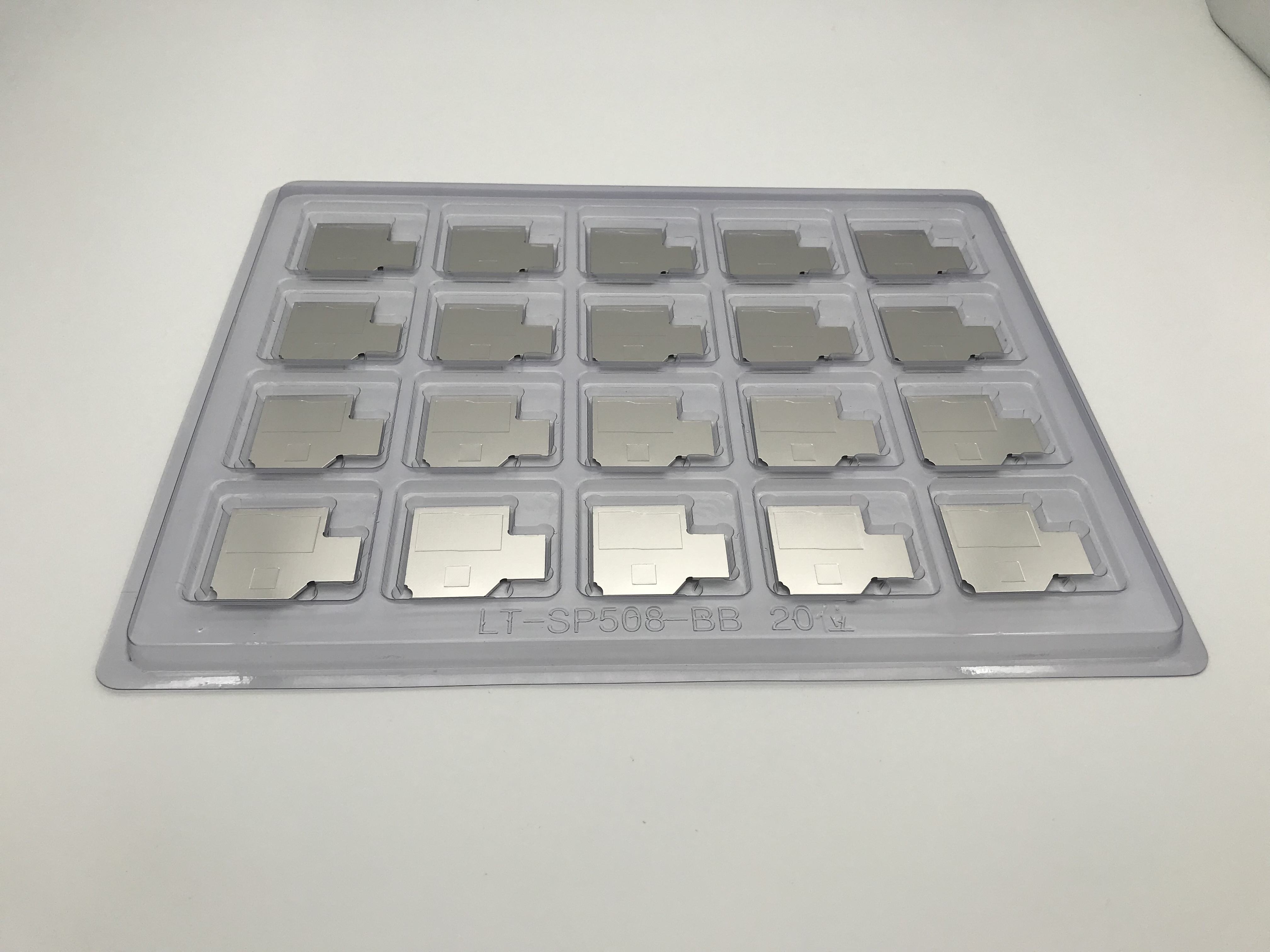

Product packaging

VIEW MORE

Related Products

-

Affordable Plastic Flooring Membrane PVC Bus and Coach Flooring

Package: Inner paper tube + outer kraft paper sleeve Plastic molding type: extrusion application: Auto parts weight: 2.3kg/square meter±0.2kg brand: Wuxi Bayi Place of origin: Jiangsu, China Specification: 2mm*2m*20m raw material: Environmentally friendly raw materials payment terms: L/C, Western...... -

Widely used in custom processing of commodity injection mold components, mobile phone casing injection mold plastics

brand: strange person Plastic molding type: injection payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram Mold forming: plastic products port: Shenzhen Port Product Keywords: Plastic injection molded parts Injection system: cold runner Key words: OEM plastic parts injection molding...... -

New rotating plastic water tank RV water purification sewage oil water tank car accessories PE processing mobile bucket with wheels

model: tank brand: Udy Plastic molding type: Rotational molding port: China Processing services: cutting, forming Origin: Guangdong, China payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram Material: polyvinyl alcohol plastic fuel tank roll plastic water tank... -

Wood grain environmental protection wear-resistant vinyl bus floor roll linoleum floor roll

port: Shanghai port MOQ: 2 volumes weight: 2.3kg/square meter ±0.2kg Plastic molding type: extrusion Packaging Details: Each roll has a paper tube inside and a kraft paper cover on the outside. model: 218-3 Specification: 2mm*2m*20m color: According to your requests product name: Vinyl Bus Flooring.... -

Original activated carbon container oil tank activated carbon canister

size: Original size (21cm*10cm10cm) payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram model: GRKJ-ZCC-03 port: Shenzhen MOQ: 100 color: transparent brand: GRKJ brand: GRKJ Origin: Guangxi, China Product Description Product Description Specification Specification Warranty 12 months...... -

Hot sale steel high elastic steel wire reinforced flexible PU hose for wood processing machinery industrial piping

Origin: Shandong Province, China Package preview: color: to clear application: painting vacuum: 0.50 bar Overpressure: 2.00 bar MOQ: 10 m product name: polyurethane hose model: GS041 payment terms: L/C, D/P, D/A, T/T, PayPal Material: Polyurethane brand: yum Plastic molding type: Rotational molding.... -

Plastic fuel tank processing speedboat marine machinery 2L 4L 6 small capacity diesel tank fuel tank

Plastic molding type: Rotational molding brand: Udy model: tank port: China payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram Material: polyvinyl alcohol Origin: Guangdong, China Processing services: cutting, forming plastic fuel tank... -

ABS PPS PA66 PC Custom Manufacturing Injection Mold & Parts Injection Molding Transparent Other Plastic Products

port: Shenzhen Port Certificate: ISO9001 application: car parts Product Keywords: injection model product name: Automotive Plastic Parts Material: ABS Mold forming: plastic products Key words: OEM Plastic Parts Injection Molding Package preview: Plastic model type: injection Supply capacity: 50...... -

Wholesale custom silicone tube car intercooler silicone tube shaped tube

Package preview: Packaging Details: Standard export carton packaging Supply capacity: 50000 pieces per month Origin: Fujian China payment terms: Western Union, T/T, MoneyGram, Trade Assurance color: custom color ID: custom logo size: custom size port: Ningbo/Shanghai Product Description...... -

SGCB 4pcs Pegboard Organizer Workshop Garage Storage Pro ABS 15x15 Inch Pegboard Panel Auto Detailing Set Tool Organizer System

port: Guangzhou, China Packaging Details: 12pcs/19.9kg/53*40.5*40cm per carton Origin: China model: SGGD323 SGGD324 Supply capacity: 10000 pieces per month payment terms: L/C, Western Union, T/T brand: SGCB Product Description SGCB Pegboard Organizer * Strong ABS material* Easy to install* whatever....