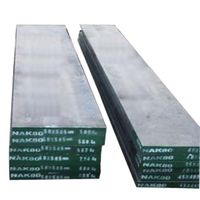

1.2379 round and flat bars

- $2600.00 /piece

- 1 piece

- Huangshi Pinxin Industrial Co., Ltd.

- Hubei, China

- Mr LEWIS WANG

Product Detail

| Supply capacity: | 100,000 tons per year | grade: | 1.2379 |

| brand: | Pinxin | Processing services: | to cut |

| Origin: | Hubei, China | thickness: | 1mm-500mm |

| Packaging Details: | According to export packing | tolerant: | ±5% |

| product name: | 1.2379 | model: | Thickness 1.5 to 500 |

| Package preview: | standard: | other | |

| payment terms: | L/C, Western Union, D/P, T/T | type: | iron plate |

| Special Purpose: | Wear-resistant steel | application: | injection mold |

| port: | Huangshi, Shanghai, Shenzhen, Qingdao, Dalian | Certificate: | ISO9001 |

| delivery time: | 31-45 days |

company

Product Description

1.2379 is a tool steel with a carbon content of 1.5% and a chromium content of 11.5%. After heat treatment, the hardness can reach 60HRC. It is a kind of semi-stainless steel. D2 steel has good wear resistance and moderate toughness. The disadvantage is that the corrosion resistance is slightly insufficient. It is a more suitable steel for practical use. Bob Dozier loves to use the D-2. D2 steel is a high wear-resistant, micro-deformation cold-working die steel, and wind-hardened tool steel. D2 steel can be used to manufacture cold work die steel with large cross-section, complex shape, high impact resistance and high wear resistance, such as silicon steel sheet die, cold cutting scissors, trimming die, etc.

Basic Information

1.2379 The high carbon and high chromium cold work die steel widely used in the world is ledeburite steel with high

Hardenability, hardenability and high wear resistance; good high temperature oxidation resistance, rust prevention after quenching

Good polishing performance, small heat treatment deformation.

hardness

Annealing≤255HB, indentation diameter≥3.8mm;

Quenching≥59HRC

Heat Treatment Specifications

Quenching, preheating at 820±15°C, heating at 1000±6°C (salt bath) or 1010±6°C (furnace controlled atmosphere),

Keep warm for 10-20min, air-cool, and temper at 200±6°C.

Material properties

1.2379 steel is a kind of high wear-resistant micro-deformation cold work die steel, which belongs to wind hard tool steel. quality

The carbon content in the steel is as high as 1.5%, and the chromium mass fraction is as high as 11.5%. After heat treatment,

The hardness can reach 60HRC, but the plasticity, toughness and anti-rust ability are weak, and the steel surface

Difficult to mirror polish. With the development of cold stamping products in the direction of high precision, high efficiency and high precision

There are many varieties, and the mold steel is required to have good wear resistance and toughness. Compared with Cr12MoV steel,

The chemical composition of the steel increases Mo and V, changes the casting structure of the steel, and improves the

The shape of the cabochon. The strength, toughness and wear resistance are all better than Cr12MoV steel, which improves

Mold use. Life. Because the yield point and plastic deformation resistance of the steel are higher than that of Cr12MoV

The forging performance and thermoplastic formability of the steel are slightly worse than those of Cr12MoV steel.

reference level

China GB standard grade Cr12Mo1v1

American ASTM/UNS standard grade D2/T30402,

International Organization for Standardization (ISO) standard grade 160CrMoV12,

German DIN standard material number 1.2379,

German DIN standard brand X155CrMoV12-1,

French NF standard grade X160CrMoV12,

British BS standard grade BD2,

Japan JIS standard grade SKD11,

Hitachi (HITACHl) standard SLD,

DAIDO standard grade DC11,

Japan Fujitsu (NACHl) standard CDS11,

Austrian white deer (BOHLER) standard grade K110,

Swedish ASSAB standard grade XW41

scope of use

Various cold stamping dies suitable for complex and deformable tool steel, high wear resistance and long life

Life, cold shear blade, thread rolling plate; cold extrusion molding, drawing die, stainless steel sheet and high hardness

Material. mode etc.

typical application

1) It is used for the drawing die of the back cover of the refrigerator compressor, and the quenching hardness is 56~58HRC.

2) In order to improve the service life of D2 cold working die flat steel rolled products, the method of adding rare earth is

Using this technology, the wear resistance and impact toughness of steel are greatly improved, so as to achieve the purpose of improving steel.

Service life of round die flat steel rolled material.

3) Since the content of V and Mo in 1.2379 steel is higher than that of Cr12MoV steel, it has better comprehensive performance, and at the same time

The traditional Cr12MoV steel will be gradually replaced.

4) The cold punching die of the roller and the adjustment plate under the table is made of D2 steel, which can increase the service life by 5-6 years

Compared with Cr12MoV steel.

1.2379 The high carbon and high chromium cold work die steel widely used in the world is ledeburite steel with high

Hardenability, hardenability and high wear resistance; good high temperature oxidation resistance, rust prevention after quenching

Good polishing performance, small heat treatment deformation.

hardness

Annealing≤255HB, indentation diameter≥3.8mm;

Quenching≥59HRC

Heat Treatment Specifications

Quenching, preheating at 820±15°C, heating at 1000±6°C (salt bath) or 1010±6°C (furnace controlled atmosphere),

Keep warm for 10-20min, air-cool, and temper at 200±6°C.

Material properties

1.2379 steel is a kind of high wear-resistant micro-deformation cold work die steel, which belongs to wind hard tool steel. quality

The carbon content in the steel is as high as 1.5%, and the chromium mass fraction is as high as 11.5%. After heat treatment,

The hardness can reach 60HRC, but the plasticity, toughness and anti-rust ability are weak, and the steel surface

Difficult to mirror polish. With the development of cold stamping products in the direction of high precision, high efficiency and high precision

There are many varieties, and the mold steel is required to have good wear resistance and toughness. Compared with Cr12MoV steel,

The chemical composition of the steel increases Mo and V, changes the casting structure of the steel, and improves the

The shape of the cabochon. The strength, toughness and wear resistance are all better than Cr12MoV steel, which improves

Mold use. Life. Because the yield point and plastic deformation resistance of the steel are higher than that of Cr12MoV

The forging performance and thermoplastic formability of the steel are slightly worse than those of Cr12MoV steel.

reference level

China GB standard grade Cr12Mo1v1

American ASTM/UNS standard grade D2/T30402,

International Organization for Standardization (ISO) standard grade 160CrMoV12,

German DIN standard material number 1.2379,

German DIN standard brand X155CrMoV12-1,

French NF standard grade X160CrMoV12,

British BS standard grade BD2,

Japan JIS standard grade SKD11,

Hitachi (HITACHl) standard SLD,

DAIDO standard grade DC11,

Japan Fujitsu (NACHl) standard CDS11,

Austrian white deer (BOHLER) standard grade K110,

Swedish ASSAB standard grade XW41

scope of use

Various cold stamping dies suitable for complex and deformable tool steel, high wear resistance and long life

Life, cold shear blade, thread rolling plate; cold extrusion molding, drawing die, stainless steel sheet and high hardness

Material. mode etc.

typical application

1) It is used for the drawing die of the back cover of the refrigerator compressor, and the quenching hardness is 56~58HRC.

2) In order to improve the service life of D2 cold working die flat steel rolled products, the method of adding rare earth is

Using this technology, the wear resistance and impact toughness of steel are greatly improved, so as to achieve the purpose of improving steel.

Service life of round die flat steel rolled material.

3) Since the content of V and Mo in 1.2379 steel is higher than that of Cr12MoV steel, it has better comprehensive performance, and at the same time

The traditional Cr12MoV steel will be gradually replaced.

4) The cold punching die of the roller and the adjustment plate under the table is made of D2 steel, which can increase the service life by 5-6 years

Compared with Cr12MoV steel.

Specification

Round steel | Diameter 1.5-500MM |

sheet | Thickness 0.5-10MM |

plate | Thickness 12-300MM |

mold block | Thickness 310-600MM |

VIEW MORE

Related Products

-

Good machinability 10-450mm S50C Carbon tool steel plate for mold and tool

grade: DC53 D2 Cr12MoV D3 O1 HMD5 5CrNiMo S50C shape: plate Place of origin: Shandong Province, China Minimum order quantity: 1 ton surface: Black thickness: 3-300mm Processing services: Welding, punching, cutting, bending, uncoiling delivery time: 8-14 days Whether alloy: alloy standard: AiSi,...... -

Forged round bar forged steel 1.2714 1.2344 1.2311 1.2312 4340 4130 alloy steel die steel GB

port: Ningbo Port Cold work die steel: 1.2344 Supply capacity: 200,000 tons/year Processing services: Cutting, punching, milling product name: Shield machine knife ring Place of origin: Zhejiang, China Production Process: forging tolerant: ±3% application: Mold making grade: 1.2344 delivery time:...... -

Hastelloy, C-276, C-2000, C-22

Packaging details: Shipping standard packaging Package preview: Certificate: ISO9001 Place of origin: China brand: Dongmeng Steel delivery time: 7-10 days Species: Industrial supplies standard: GB, ASTM, EN tolerant: ±1% product name: Hastelloy port: Qingdao, Tianjin Port, Shanghai Port, etc....... -

Cold Stamping Casting ASTM Hot Forging Die Steel D2 O2 H13 Tool Steel Panel Die Steel

length: 200-6000mm payment terms: L/C, T/T standard: ASTM GB DIN, ASTM MOQ: 1 item Packaging Details: Standard airworthy packing or according to customer's requirement application: mold making Supply capacity: 1000 tons per month Processing services: welding, bending Surface treatment: black...... -

1.2379 Forged or rolled round bars

Special Purpose: Wear-resistant steel product name: 1.2379 thickness: 1mm-500mm tolerant: ±5% delivery time: 31-45 days type: iron plate model: Thickness 1.5 to 500 brand: Pinxin Packaging Details: According to export packing Certificate: ISO9001 Processing services: to cut Package preview: port:...... -

High quality AISI forged steel P20 P20+ P20+Ni 1.2311 718 738 3Cr2Mo stock plastic sheet mold steel round bar bar

main application: For pre-hard pouring medium and large plastic molds port: Shenzhen application: Plastic Mold Steel thickness: 20-180mm Package preview: Molding: Hot rolled or hot forged Packaging Details: Vane Manufacture AISI 4340 Gear Steel 1.6511 Polished Plate Prices Ship by 20FT or 40HQ....... -

mold steel 1075 H13 D2 D3 P20 SKD11 Cr12 alloy spring steel plate tool steel

Supply capacity: 300,000 tons/year process: drilling thickness: 2-500mm brand: kunda product name: Alloy die steel color: metallic color pricing term: CIF CFR FOB ex-factory price Package: bundled packaging tolerant: ±5% payment terms: L/C, Western Union, T/T Package preview: port: Tianjin or...... -

NOS416 Die Steel Work Heat

port: Tianjin Xingang, Beijing Port, Qingdao Port Origin: China Certificate: ISO9001 Supply capacity: 20,000 tons/year standard: National standard delivery time: 46-60 days payment terms: L/C, T/T grade: alloy steel Specification NOS416 International steel grade Americas (AISI) H11 module Germany...... -

NOS420 Die Steel

Origin: China payment terms: L/C, T/T port: Tianjin Xingang, Beijing Port, Qingdao Port grade: alloy steel Supply capacity: 20,000 tons/year Certificate: ISO9001 standard: National standard delivery time: 46-60 days Specification NOS420 International steel grade China (GB) 4Cr5Mo2V Germany (German..... -

Alloy steel stainless steel converter tube/tetrafluoro steel tube

style: Design as required Certificate: ISO9001 payment terms: L/C, D/P, D/P, T/T Processing services: Welding, punching, cutting, bending, decoiling Package preview: port: Shanghai grade: 300 900 series Origin: Jiangsu, China Packaging Details: Packaged in seaworthy wooden case or as your request......