TPU raw material thermoplastic polyurethane TPU mixing pellets 100% virgin TPU shoe material pellets

-

$3.68 / 1 - 99 kilograms

$3.28 / 100 - 999 kilograms

$2.88 / >=1000 kilograms - 1 kilogram

- Shenzhen Dome Materials Co., Ltd.

- Guangdong, China

- Ms Cimy Zhou

Product Detail

| Advantage: | Oil-resistant, waterproof, mildew-proof and impact-resistant | application: | TPU for shoes |

| Tear strength (KN/m): | 45-200 | Tensile strength (Mpa): | 18-55 |

| Packaging Details: | Packed in plastic box or carton lined with PE bag. Please store in dry and ventilated conditions; Avoid sunlight; Please seal the unused product; Please use it up within 24 months. | payment terms: | L/C, Western Union, T/T, MoneyGram |

| density: | 1.1-1.22 | grade: | Injection extrusion grade TPU pellets |

| brand: | dome | color: | Transparent/custom |

| port: | Shenzhen/Guangzhou/Shanghai | product name: | TPU plastic raw material |

| full name: | Thermoplastic Polyurethane TPU Granules | Origin: | Guangdong, China |

| Package preview: | Supply capacity: | 800 tons per month | |

| Hardness range: | 70A/75A/80A/85A/90A/95A/98A | model: | DM-TPU8027 |

Product Description

Specification

thing | value |

birthplace | China |

Guangdong | |

brand | dome |

model | DM-TPU8027 |

product name | TPU plastic raw material |

full name | Thermoplastic Polyurethane TPU Granules |

color | Transparent/custom |

application | TPU for shoes |

Hardness range | 70A/75A/80A/85A/90A/95A/98A |

density | 1.1-1.22 |

grade | Injection extrusion grade TPU pellets |

Advantage | Oil-resistant, waterproof, mildew-proof and impact-resistant |

Tensile strength (Mpa) | 18-55 |

Tear strength (KN/m) | 45-200 |

Wear amount, mm3 | 45-100 |

300% tensile stress, Mpa | 3-38 |

Elongation at break, % | 350-900 |

Compression set at 70°C, % | 35-60 |

Processing temperature, ℃ | 185-205 |

Advantage | 1. Competitive price, high quality, on-time delivery, free samples 2. Environmental protection 3. High heat resistance, high impact resistance 4. No impurities 5. It can be reinforced with glass fiber/toughening/flame retardant/UV stabilizer |

feature | 1. Wear resistance. TPU plastic material has excellent wear resistance, which is more than five times that of natural rubber. 2. Tensile properties. The tensile strength can reach 70MPa, and the elongation at break can reach 1000%. 3. Tear performance. TPU is highly tear-resistant, with a tear strength much higher than many commonly used rubbers and plastics. 4. Folding performance. TPU products can maintain excellent bending resistance in different environments, and are one of the best choices for polymer materials. 5. Hydrolysis resistance. TPU has good water resistance in turbid state, and there is no obvious hydrolysis phenomenon in 1~2 years, especially the polyether series. 6. High temperature resistance and oxidation resistance. TPU has good oxidation resistance; temperature resistance can reach 120°C. 7. Oil and chemical resistance. TPU has very little affinity with non-polar mineral oil, and it is used in fuel oil (such as kerosene, gasoline) and mechanical oil (such as hydraulic oil, lubricating oil, etc.). 8. Low temperature performance. The low temperature resistance of TPU can usually reach -50°C, which can replace general PVC that cannot be used in various fields due to low temperature embrittlement, and is especially suitable for use in related types of products in cold regions. 9. Air tightness. TPU is very easy to weld with high-frequency waves or heat and pressure, so it is widely used in inflatable products. 10. Biomedical properties. TPU has excellent biocompatibility, non-toxic, no allergic reaction, no local irritation, no heat, so it is widely used in medical, health care and other related products, as well as sports and protective products. |

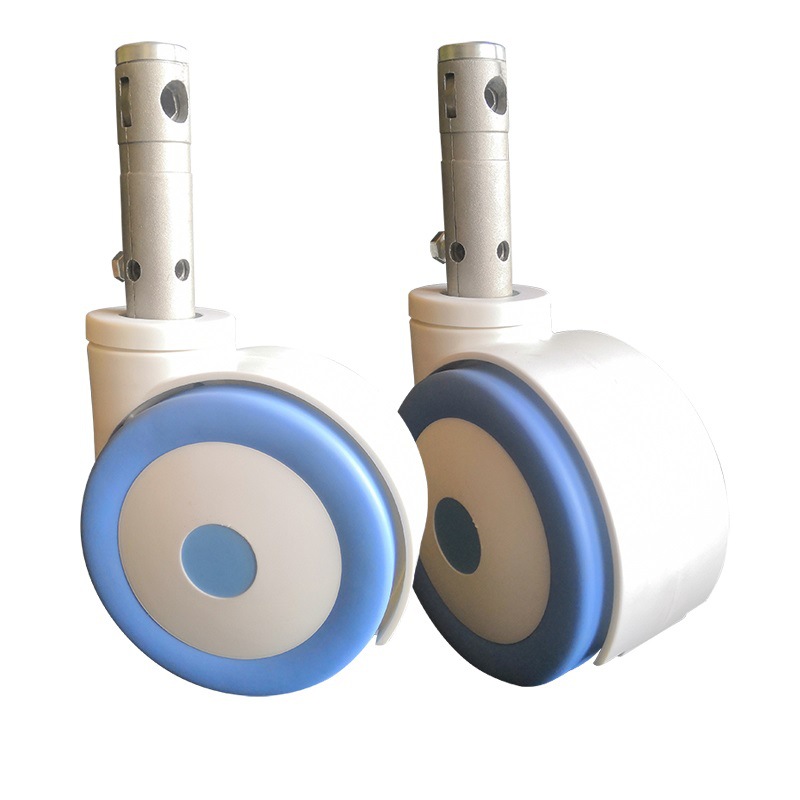

application | Footwear use: soles, shoe decorations, snow boots...etc. Wheel usage: Skate wheels, casters, road wheels...etc. Industrial parts use: O-rings, oil seals, gaskets, etc. Mobile phone use: mobile phone protective case, mobile phone accessories, etc. |

pack | 25KG per box |

payment terms | TT, LC, Western Union, etc. |

delivery time | Within 7-10 days |

MOQ | 1kg and free sample |

Product parameters

TPU material is widely used in film products because of its excellent performance. And according to the different uses of TPU film, we

It is recommended that you use different TPU materials, including polyester TPU, polyether TPU, etc.

It is recommended that you use different TPU materials, including polyester TPU, polyether TPU, etc.

performance item | Test Methods | Test Data | data unit |

hardness | ASTM D2240 | 90 | A shore |

density | ASTM D792 | 1.2 | g/cubic centimeter |

modulus | ASTM D412 | 7 | MPa |

300% modulus | ASTM D412 | 12 | MPa |

tensile strength | ASTM D412 | 37 | MPa |

elongation | ASTM D412 | Chapter 460 | % |

tear strength | ASTM D624 | 100 | N/mm |

performance item | 65A | 70A | 75A | 80A | 85A | 90A | 95A | 98A | 64D |

dDensity cm³(ISO1183) | 1.10±0.02 | 1.14±0.02 | 1.20±0.02 | 1.20±0.02 | 1.21±0.02 | 1.21±0.02 | 1.21±0.02 | 1.22±0.02 | 1.22±0.02 |

hardness, Shore A/D (ASTM D2240) | 65±3 | 70±3 | 75±3 | 80±3 | 85±3 | 90±3 | 95±3 | 98±3 | 64D±3 |

300% tensile stress, Mpa (ISO37) | 3 | 4.5 | 6.5 | 9.0 | 11 | 15 | twenty two | twenty four | 33 |

Tensile strength, Mpa(ISO37) | 18 | 29 | 33 | 36 | 43 | 50 | 51 | 52 | 54 |

Elongation at break, %(ISO37) | 900 | 800 | 800 | 700 | 600 | 550 | 500 | Chapter 480 | Chapter 420 |

Tear strength, KN/m(ISO34) | 45 | 55 | 80 | 90 | 100 | 110 | 130 | 150 | 170 |

Compression set at 70℃, %(ISO81) | 35 | 40 | 40 | 40 | 45 | 45 | 50 | 50 | 55 |

Abrasion, mm³(ISO46) | 100 | 70 | 60 | 55 | 50 | 50 | 45 | 45 | 45 |

TPU is thermoplastic polyurethane, which can be divided into polyester type and polyether type. It has a wide hardness range (60ha-85hd), wear resistance, oil resistance, transparency and good elasticity. Widely used in daily necessities, sporting goods, toys, decorative materials, etc. Halogen-free flame-retardant TPU can also replace soft PVC to meet environmental protection requirements in more and more fields. There are many brands of TPU with varying quality. It is best to go through detailed evaluation and demonstration when choosing a TPU, otherwise the best result of cost performance cannot be obtained. TPU has a wide range of hardness, high strength, friction resistance, good toughness, good elasticity, cold resistance, oil resistance, water resistance, aging resistance, weather resistance and other incomparable characteristics of other plastic materials. At the same time, it also has many excellent functions such as high waterproof, moisture permeability, wind resistance, cold resistance, antibacterial, mildew resistance, heat preservation, UV resistance, and energy release. Widely used in shoe materials, luggage materials, sports equipment, medical equipment, automobile industry, packaging products, wire and cable covering materials, hoses, films, coatings, inks, adhesives, melt-spun spandex fibers, artificial leather, and bonded clothing etc. Gloves, inflatable products, agricultural greenhouses, air transport, defense industry.

The main characteristics of TPU

Wide range of hardness: By changing the ratio of the reactive components of TPU, products with different hardness can be obtained, and with the increase of hardness, the product still maintains good elasticity and wear resistance.

High mechanical strength: TPU products have excellent bearing capacity, impact resistance and shock absorption performance.

outstanding cold resistance: The glass transition temperature of TPU is low, and it still maintains good physical properties such as elasticity and flexibility at -35 degrees.

good processing performance: TPU can be processed by common thermoplastic material processing methods, such as injection molding, extrusion, calendering, etc. At the same time, TPU and certain polymer materials can be processed together to obtain polymer alloys with complementary properties.

※ 17 years of production experience in the plastics industry.

※ Customized service according to your inquiry.※ Advanced testing and manufacturing equipment.

※ Competitive factory price.

※ professional service.

※ Fast delivery and free samples.

※ 24*7 hours after-sales service

Applications:

TPU has a variety of applications including automotive dashboards, casters, power tools, sporting goods, medical devices, power transmission belts, footwear, inflatable rafts, and a variety of extruded film, sheet, and profile applications. TPU is also a common material in housings for mobile electronic devices such as cell phones. It is also used to make keyboard protectors for laptops. TPU is known for its use in high-performance films, wire and cable jacketing, hose and tubing, adhesive and textile coating applications, and as an impact modifier for other polymers. TPU particles are used as adidas' latest cushioning technology called Boost. Thousands of TPU particles are bonded together to create a comfortable sole.

VIEW MORE

Related Products

-

TPU film roll manufacturer--Highly scratch-resistant Materi TPU film---Silver/gold/red/rose gold logo film

Material: 100% polyester TPU model: No Place of origin: Guangdong, China width: According to customer requirements Package preview: Packaging details: Roll or pallet brand: No feature: Scratch resistant hardness: 85A-97A payment terms: L/C, Western Union, D/P, D/A, T/T application: logo China's...... -

Custom Thickness Transparent Vinyl Fabric TPU Clear Film For Handbags Cosmetic Bags Gift Crafts

Supply capacity: 20000 meters per day Packaging Details: 30m/or with plastic bag + shipping mark + color sample or according to your requirements product name: Transparent TPU Film Transparent Vinyl Fabric port: Xiamen/Shenzhen/Shanghai backing: Woven backing delivery time: 5-15 days model: X-5006..... -

Thermoplastic Polyurethane Mirathane M-Series TPU Polyether-based TPU pellets designed for composite film and sheet extrusion

Package preview: Supply capacity: 1000 metric tons per month application: automotive industry; industrial machinery thing: thermoplastic polyurethane grade: injection molding MOQ: 1 ton port: Tianjin model: M70 characteristic: electric Origin: Hebei china pack: Bag form: Grain; Granules; Resin...... -

High transparent TPU thermoplastic polyurethane plastic raw material pellets TPU manufacturer price TPU pellets

type: raw/recycled pack: 25kg/bag hardness: 70A/75A/80A/85A/90A/95A/98A Packaging Details: 25kg per bag, the packaging can be customized, please contact us if you have any requirements. Supply capacity: 5000 tons per week application: Soles, mobile phone cases, etc. model: thermoplastic...... -

Electroplated metal gold and silver TPU film for shoes and bags

MOQ: 300㎡ delivery time: 7-10 days after payment hardness: 80A, 85A, 90A, 95A Material: TPU+Foil port: Shenzhen, Guangzhou application: Labels, badges, brand logos, shoes, etc. width: 1350mm (accept customization) Origin: Guangdong, China brand: Green TPU payment terms: L/C, Western Union, T/T,...... -

TPU raw material vamp free of sewing and lamination Trademark and label TPU high and low temperature film TPU film for frosted shoes

appearance: matte / matte model: LK-TPU-001 hardness: 80A 85A 90A 95A thickness: 0.35MM Packaging Details: Standard size 137CM*50Y/roll, inner cardboard tube, PE cover, outer kraft carton. product name: TPU is resistant to high and low temperatures. Movie application: Shoe material stitch-free...... -

Thermoplastic Polyurethane TPU Resin TPU Wheat Straw Biodegradable Plastic Granules Based Raw Materials Different Fibers

grade: injection Supply capacity: 20 metric tons per day Packaging Details: 25 kg/bag, 1 ton (40 bags)/pallet, 20 tons/20ft container Certificate: ROHS Directive Material: wheat straw model: TPU fiber color: Nature brand: RFD Origin: Guangdong, China application: packaged food payment terms: L/C,...... -

Transparent TPU film

brand: human resources department hardness: 80A 85A 90A 95A Package preview: sample: supply usage: screen printing port: Shenzhen pack: Roll Packaging Details: 0.1mm 250y/roll 0.15mm 200y/roll 0.18mm 150y/roll 0.2mm 150y/roll 0.3mm 100y/roll 0.5mm 60y/roll Supply capacity: 10000 yards per week...... -

Environmentally friendly glossy TPU film soft polyurethane sheet for raincoat bag label film

application: bags and raincoats thickness: 0.1-1.0(mm) sample: freely size: 48"/54" other widths can be customized Origin: Guangdong, China model: TPU film-110 brand: Joy rhyme payment terms: Western Union, T/T product name: TPU film color: Frosted TPU film feature: environmentally friendly port:...... -

Factory direct selling high elastic TPU transparent matte film polyurethane transparent film TPU film

Material: 100% thermoplastic polyurethane color: transparent size: 48"/54" other widths can be customized Supply capacity: 10000 kg per day port: Shenzhen payment terms: Western Union, T/T sample: freely thickness: 0.1mm-1.0mm(mm) feature: environmentally friendly application: Phone Cases and......