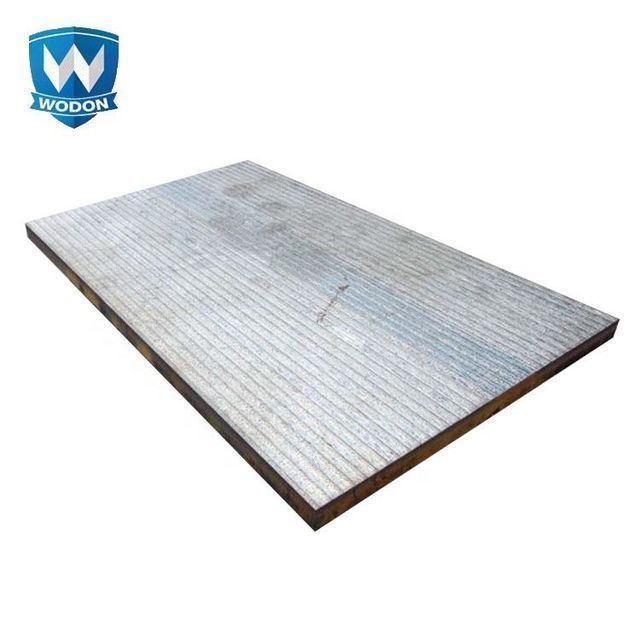

Good impact resistance bimetal cladding hardening composite wear-resistant composite plate

-

$296.59 / 1 - 49 square meters

$251.59 / 50 - 99 square meters

$120.59 / >=100 square meters - 1 square meter

- Tianjin Wodon Wear Resistant Material Co., Ltd.

- Tianjin, China

- Mr Alexander Zhang

Product Detail

| Executive position: | Enterprise standard | Packaging Details: | in steel trays. |

| place of origin; place of origin: | Tianjing, China | Processing service: | Bending, welding, cutting, punching |

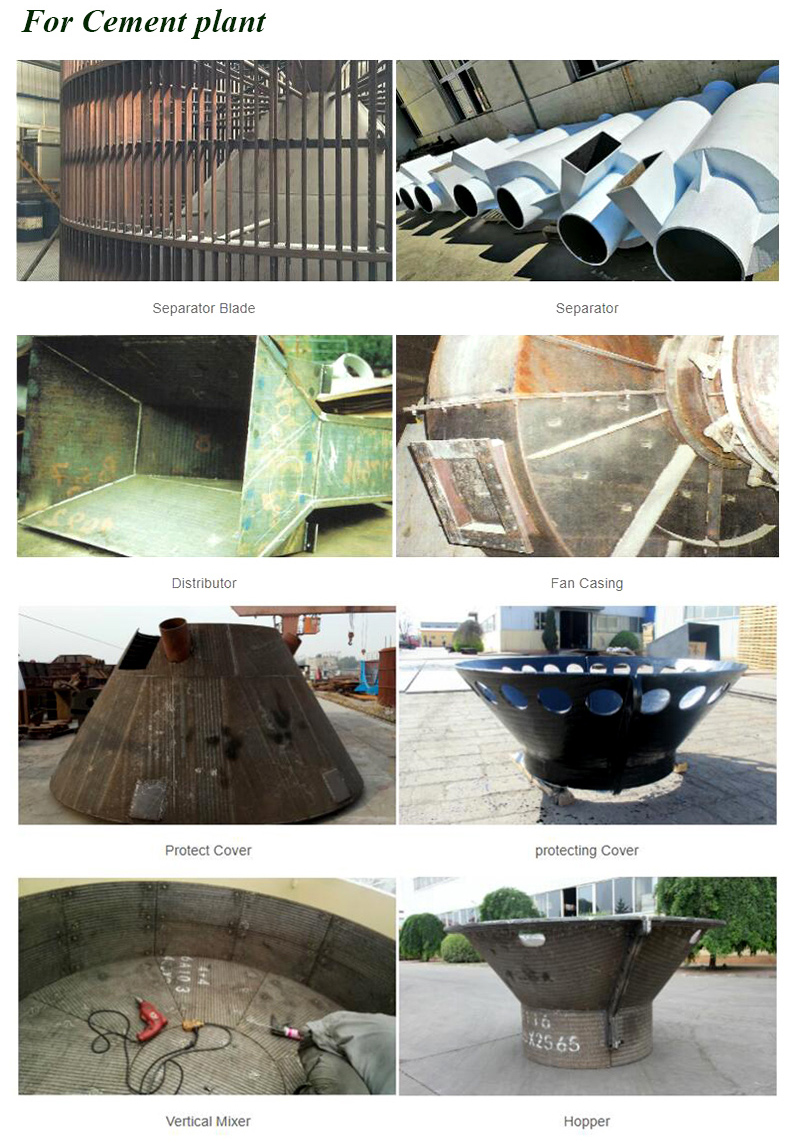

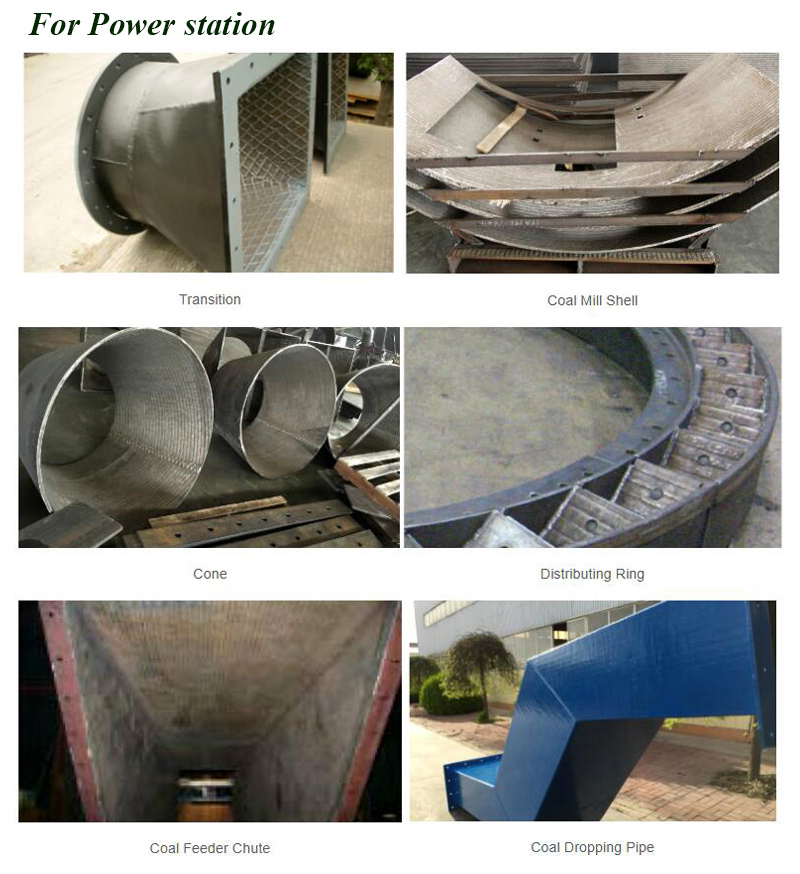

| Special Purpose: | Wear-resistant steel | application: | Mine Liners, Cement Plants, Power Plants, Flanges |

| model: | 3+3, 4+4, 5+5, 6+6, 8+8, 10+10, 12+12, etc. | Chassis: | Q235, Q345, SS400, A36, etc. |

| Cladding Thickness Tolerance: | 0-0.5mm | standard: | Aisi,ASTM,bs,DIN,GB,JIS |

| Certificate: | ISO9001 | tolerant: | +/-1% |

| Microstructure content: | The volume fraction of Cr7C3 exceeds 50% | Gross weight per piece: | 10.000 kg |

| technology: | case hardening | Sales unit: | single product |

| Surface treatment: | case hardening | hardness: | 55 - 65 HRC |

| length: | customer request | grade: | Chromium carbide cover plate |

| chemical composition: | C 3-5; Chromium 25-40 | brand: | Wharton |

| type: | steel plate, steel plate | Flatness tolerance: | ±3mm/m |

| Packaging Preview: | product name: | Resistance bimetal cladding hardening composite wear-resistant composite plate | |

| width: | customer request | Single package size: | 30X30X30 cm |

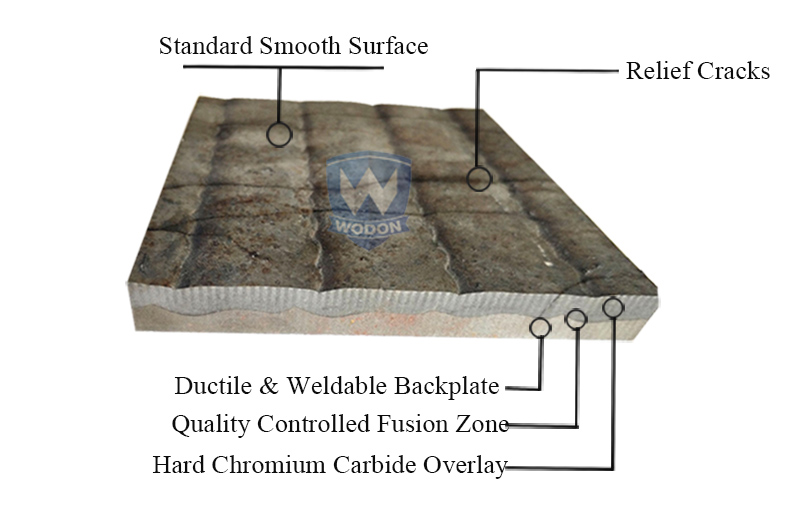

Wodon wear plates are made by welding one or more wear layers to a medium carbon or mild steel substrate. Surfacing alloys contain large amounts of chromium

Carbide hard particles give the sheet good wear and impact resistance.

High chrome version of ordinary excavator bucket steel bimetallic sheet bimetallic plate

The chromium carbide surfacing wear plates we manufacture:

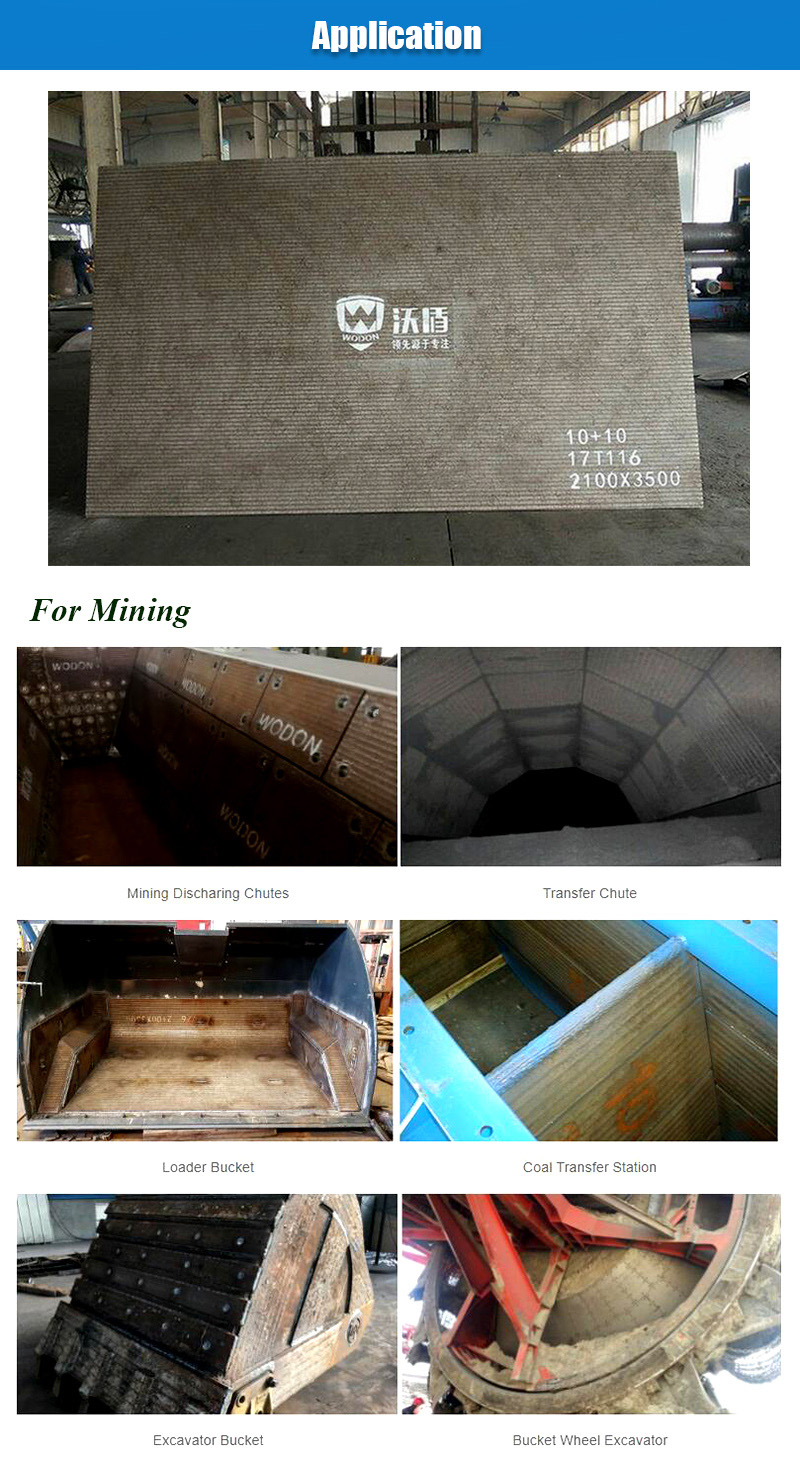

* Thickness: 3+3mm, 4+4mm, 5+5mm, 6+6mm....20+20mm, 40+30mm, etc.

* Plate size: 1400*3400mm, 1400*3500, 2100*3500mm, etc.

* Chemical composition: C, Cr, Mn, Si, Fe, etc.

* Hardness: HRC 58-65

* Welding: submerged arc and open arc

Chromium carbide covered wear plates

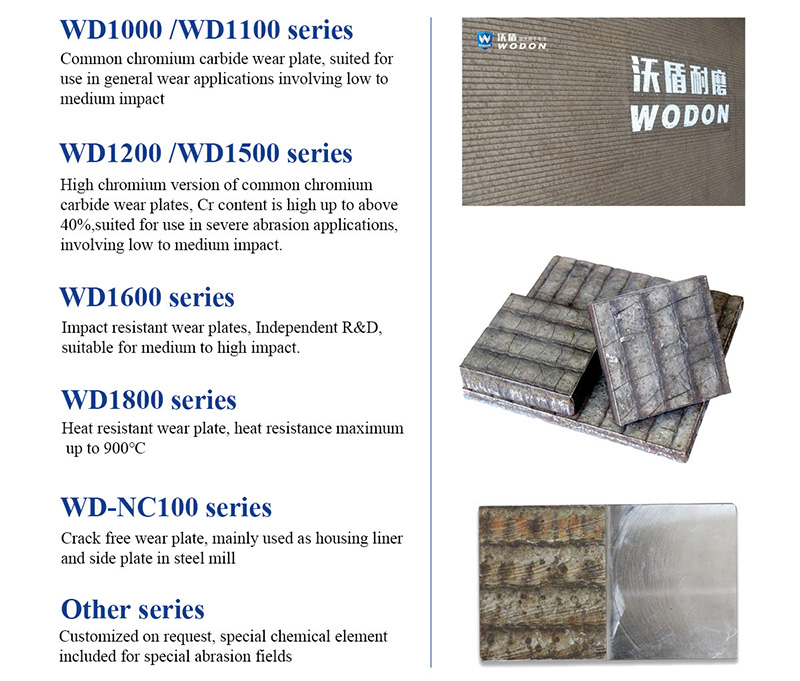

| Model | feature | hardness | chemical composition(%) | Operating temperature | ||||||

| (Human Rights Commission) | C | chromium | manganese | silicon | Molybdenum + Niobium | Nickel + Vanadium + Tungsten | iron | |||

| WD-1000 | Plain chrome carbide wear plates for general wear applications involving low to medium impact | 58-65 | 3.0-5.0 | 17.0-27.0 | 1.0-3.0 | 1.0-3.0 | / | / | Barr. | <400℃ |

| WD-1100 | ||||||||||

| WD-1200 | High chromium carbide wear plate with Cr content up to 40% or more, suitable for severe wear applications involving low to medium impact. | 58-65 | 3.0-6.0 | 25.0-45.0 | 1.0-3.0 | 1.0-3.0 | / | / | Barr. | <400℃ |

| WD-1500 | ||||||||||

| WD-1600 | Impact-resistant wear-resistant plate, independently developed, suitable for medium and high impact. | 58-65 | 3.5-6.5 | 25.0-45.0 | 1.0-3.0 | 1.0-3.0 | * | / | Barr. | <600℃ |

| WD-1800 | Heat-resistant wear-resistant plate, heat-resistant up to 900℃ | 58-65 | 4.0-7.0 | 25.0-40.0 | / | / | * | * | Barr. | <900℃ |

| WD-NC100 | Crack-free wear plates, mainly used as shell liners and side plates in steel mills | 50-55 | ||||||||

| other series | Can be customized on request, including special chemical elements for special wear areas | / | ||||||||

| Plate size: 1400*3400mm 1400*3000mm 1500*3000mm 1400*3500mm 2000*3000mm 2100*3500mm others as required | ||||||||||

| Base metal material: Q235, Q345, etc. | ||||||||||

| Cladding thickness: 3-50mm | ||||||||||

d

Ustry.

Ustry.

1.Overlay chemistry is key

The main components of Wodon sheet are C (%): 3.0-5.0 and Cr (%): 25-40. This chemical ratio results in a large amount of Cr7C3 chromium carbide hard particles. The microhardness of these particles throughout the layer (up to HV1800) will guarantee a super wear-resistant surface.

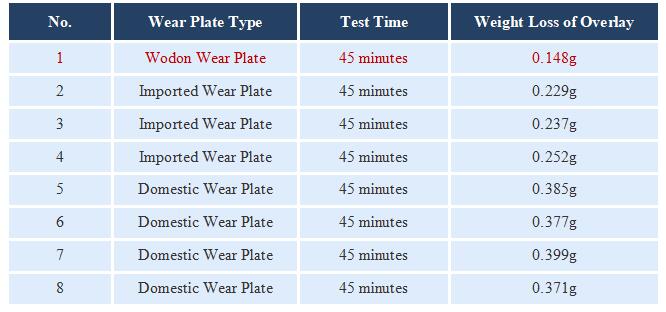

Performance Testing:

Test equipment: quartz sand rubber wheel wear tester.

Condition: The same size specimens were selected for different materials and wear plate manufacturers and subjected to the same abrasive working conditions in our test facility.

45 minutes per sample

Results: The test results show that the service life of the Woden wear plate is 2.5 times that of the domestic wear plate and 1.5 times that of the imported one.

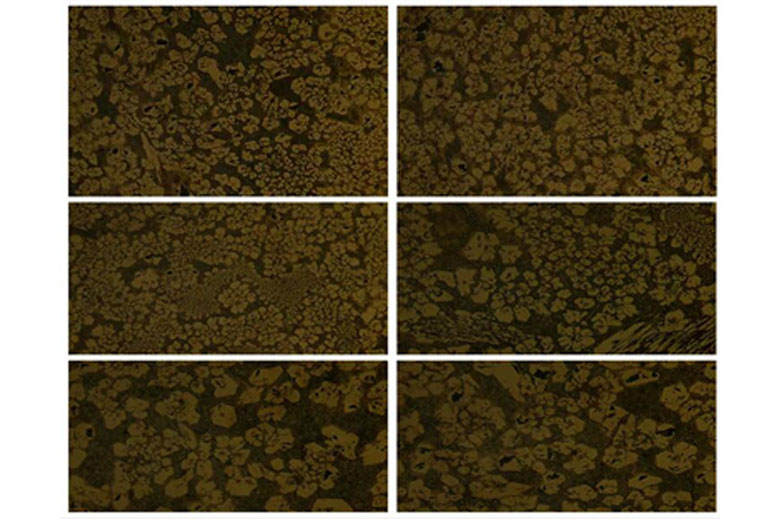

2.Chromium carbide microstructure

The wear resistance of the wear plate mainly depends on the hardness, shape, size, quantity and distribution of the chromium carbide hard particles.

As shown, the volume fraction of carbides (Cr7C3) on the microstructure exceeds 50%.

3.Adhesion strength between overlay and base plate.

The overlay and base plate are well bonded. The overlay will penetrate about 0.8mm-1.8mm to the substrate, reaching 350Mpa in our tests.

Related Products

-

High quality ASTM A572 A515 A516 standard steel carbon 1060 plate carbon steel plate

standard ASTM, AISI, SUS, JIS, EN, DIN, BS, GB, etc. Material Q195, Q215, Q235, Q345, ST37, A36, 45#, 16Mn, SPHC, SGCC, CGCC thickness Hot rolling thickness: 2.75mm-100mm Cold rolling thickness: 0.2mm-3mmAccording to your request width 45mm-2200mm, according to your requirements technology Hot...... -

Hot rolled HR Astm A36 Ss400 Q235b Q345b Q255 1065 1095 Q195 carbon steel plate iron steel plate price

application: Ship plates, boiler plates, container plates, high-strength steel plates, wear-resistant steel Supply capacity: 10 million tons/year product name: Hot rolled ship steel plate Material: Steel for Russian ships A32 A36 A40 delivery time: 15-21 days Place of origin: Shandong Province,...... -

ST37 carbon steel plate hot rolled steel carbon steel plate factory

Material: Q235/Q345/SS400/A36/St52/St37 etc. Certificate: API, CE, BIS, TISI, JIS, ISO9001, AISI, ASTM Whether alloy: It's an alloy Minimum order quantity: 5 tons Key words: 4x8 carbon steel plate Place of origin: Shandong Province, China length: 4m-12m or as required, as per buyer's requirement...... -

Carbon steel plate price per kilogram 3MM MS plate S275gr carbon steel pattern plate

bill: According to actual weight port: Tianjin, Qingdao, Rizhao, Shanghai product name: Medium thick carbon steel plate length: customer's request Material: S275gr Supply capacity: 1500 tons per week payment terms: 30% TT advance payment + 70% balance Certificate: API, CE, RoHS, SNI, BIS, SASO,...... -

High quality ASTM A36 black iron metal hot rolled steel plate Q345 A36 12mm carbon steel plate building material

MOQ: 1 ton thickness: 10mm, 12.1-50mm Processing services: Bending, welding, uncoiling, cutting, punching, welding, punching, cutting, bending, uncoiling tolerant: ±1% width: 1200-1500mm delivery time: within 7 days payment terms: L/C, Western Union, D/P, D/A, T/T Certificate: CE certification,...... -

Supply bridge plate Q690D 65Mn spring steel plate carbon steel plate

shape: flat application: Construction, ship plate, container plate, high-strength steel plate, wear-resistant steel Technical test: Bending test Certificate: CE, ISO9001 Alloy or not: Unalloyed grade: Q235/Q215/Q195/Q255 product name: carbon steel plate payment terms: L/C, T/T Certification:...... -

Hot rolled ASTM 3mm carbon steel plate

surface: Oiled, smooth, galvanized coating, others Invoicing: by theoretical weight Origin: Jiangsu, China grade: SS400, Q235, Q345R, SA302, SA516, A572, S275, S355 Alloy or not: Unalloyed Package preview: delivery time: within 7 days width: As required application: Ship plate, boiler plate,...... -

American standard high-strength alloy steel plate SA516Gr60 production and processing 3mm to 300mm thick and wide infrastructure

Supply capacity: 100,000 tons per month delivery time: 8-14 days product name: carbon steel plate application: Ship plate, boiler plate, container plate, high-strength steel plate, wear-resistant steel, plant construction, architectural steel structure, construction machinery, heavy truck, bridge...... -

LR BV CCS ABS grade AH36 high-strength steel plate A36 shipbuilding steel plate AH36 DH36 bulb parity

usage: ship building tolerant: ±5%, ±1%, ±10% Origin: Henan, China SGS BV inspection: Available, other 3rd party inspections are also available Processing services: Welding, punching, cutting, bending, decoiling Advantage: Accept customized production technology: Hot rolling, TMCP, etc. width:...... -

ASTM A537 grade 2 carbon steel plate A537 cl2 shell plate SA 537 cl2 pressure vessel steel plate price

Supply capacity: 50000 tons per month width: 2001-3000mm payment terms: L/C, Western Union, T/T Carbon steel: Yes Steel for pressure vessels: Yes length: 6001-12000mm SGS BV inspection: Available, other 3rd party inspections are also available surface: black, or customized port: Shanghai Port,......