Silicon steel sheet EI lamination for three-phase single-phase transformer core stacker use EI-66 24 25 28 33 84 96 186

- $1.80 / >=1000 kilograms

- 1000 kilograms

- Shanghai Lulu Technology Co., Ltd.

- Shanghai, China

- Ms Violet Zhuang

Product Detail

| expiration of pay: | T/T or L/C | Processing services: | Welding, cutting, stamping |

| payment terms: | L/C, T/T | type: | Non-oriented silicon steel |

| model: | EI | Surface treatment: | coating |

| grade: | Silicon steel | process: | punching |

| Material: | Chromium manganese silicon steel | port: | Shanghai, Ningbo port or other ports for your convenience |

| tolerant: | ±1% | Package preview: | |

| thickness: | 0.5 mm, 0.5 - 0.65 mm | product name: | Three-phase EI laminated silicon steel sheet |

| Steel shape: | EI | Packaging Details: | Standard international heavy cargo packaging |

| application: | Transformer core, motor core | standard: | GB, DIN, Ace, ASTM, JIS, ASTM |

| shape: | EI lamination | port: | Shanghai Port |

| Supply capacity: | 5000 tons per month | technology: | cold rolled |

| Surface treatment: | insulating paint | delivery time: | 15-21 days |

| Origin: | China Shanghai |

Product Description

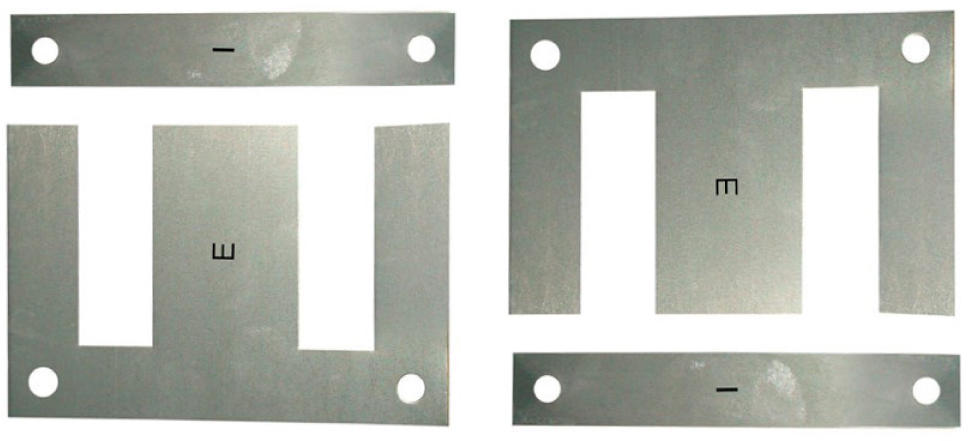

Three-phase EI laminationMade of silicon steel strip. Three-phase EI lamination models are three-phase (20) to three-phase (100), and the aperture is Φ4.5 to Φ14. The gap size of the transformer laminated core can be customized.

Lulu Technology specializes in the production of transformer cores, transformer cores, laminated cores, such as

Three-phase EI laminations, single-phase EI laminations. Now it has become an important manufacturer with the most complete models of three-phase and single-phase EI laminates in Shanghai, China.

Lulu Technology specializes in the production of transformer cores, transformer cores, laminated cores, such as

Three-phase EI laminations, single-phase EI laminations. Now it has become an important manufacturer with the most complete models of three-phase and single-phase EI laminates in Shanghai, China.

Features of three-phase EI laminations:

1) Low iron loss and high magnetic flux density

2) High dimensional accuracy, high surface quality and high accumulation coefficient

3) There is an insulating film on the surface, sound insulation performance and processing performance

1) Low iron loss and high magnetic flux density

2) High dimensional accuracy, high surface quality and high accumulation coefficient

3) There is an insulating film on the surface, sound insulation performance and processing performance

Application of three-phase EI laminations

1) Small and medium-sized industrial electrical equipment

2) Home appliance compressor

3) Power transformer

4) Welding machine transformer

5) Current regulator

1) Small and medium-sized industrial electrical equipment

2) Home appliance compressor

3) Power transformer

4) Welding machine transformer

5) Current regulator

Specification

product name | Three-phase EI core lamination |

category | Oriented electrical steel; Non-oriented electrical steel |

application | Transformer core, motor core, etc. |

thickness | Mainly 0.50mm |

Material | Central NGO |

surface treatment | coating |

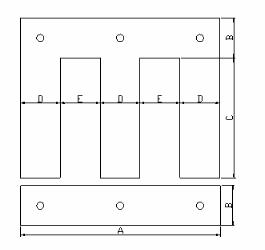

Three-phase EI lamination | ||||||||||||||||

size | A | Second | C (long) | C (short) | D. | Second | Hole | |||||||||

number | (Φ) | |||||||||||||||

EI-16 | 80 | 16 | 48 | 40 | 16 | 16 | 4 | 8 | ||||||||

EI-20 | 100 | 20 | 60 | 50 | 20 | 20 | 4 | 8 | ||||||||

EI-22 | 110 | twenty two | 66 | 55 | twenty two | twenty two | 4 | 8 | ||||||||

EI-25 | 125 | 25 | 75 | 62.5 | 25 | 25 | 4 | 8 | ||||||||

EI-28 | 140 | 28 | 84 | 70 | 28 | 28 | 4 | 8 | ||||||||

EI-30 | 150 | 30 | Post-90s | 75 | 30 | 30 | 6 | 8 | ||||||||

EI-32 | 160 | 32 | 80 | 80 | 32 | 32 | 4 | 7 | ||||||||

EI-35 | 175 | 35 | 105 | 87.5 | 35 | 35 | 4 | 8 | ||||||||

EI-36 | 180 | 36 | Post-90s | Post-90s | 36 | 36 | 6 | 8 | ||||||||

EI-38 | 190 | 38 | 114 | 95 | 38 | 38 | 6 | 8 | ||||||||

EI-40 | 200 | 40 | 120 | 100 | 40 | 40 | 6 | 10 | ||||||||

EI-44 | 220 | 44 | 132 | 110 | 44 | 44 | 6 | 8 | ||||||||

EI-45 | 225 | 45 | 135 | 112.5 | 45 | 45 | 4 | 8 | ||||||||

EI-50 | 250 | 50 | 150 | 125 | 50 | 50 | 6 | 8 or 10 | ||||||||

EI-56 | 280 | 56 | 168 | 140 | 56 | 56 | 4 | 8 | ||||||||

EI-60 | 300 | 60 | 180 | 150 | 60 | 60 | 6 | 14 | ||||||||

EI-70 | 350 | 70 | 210 | 175 | 70 | 70 | 4 | 14 | ||||||||

EI-80 | 400 | 80 | 240 | 200 | 80 | 80 | 4 | 14 | ||||||||

EI-90 | 450 | Post-90s | 270 | 225 | Post-90s | Post-90s | 4 | 14 | ||||||||

EI-100 | 500 | 100 | 300 | 250 | 100 | 100 | 4 | 14 | ||||||||

workshop display

VIEW MORE

Related Products

-

EI lamination magnetic core permalloy sheet for low frequency transformer

type: UC, non-oriented silicon steel Packaging Details: Spoo1+carton+pallet, or according to customer requirements application: Power Transformers port: Shanghai grade: Silicon steel thickness: 0.35 - 0.5mm payment terms: L/C, T/T Name: Silicon steel sheet Material Thickness: 0.35mm, 0.50mm shape:..... -

Made in Japan Transformer Core Steel Laminations for Sale Camera Module Magnetic Shield

payment terms: L/C, T/T, PyaPal standard: JIS Surface treatment: annealing delivery time: 31-45 days model: P3 7 Supply capacity: 10kg per month grade: high permeability All "Made in Japan" materials: high permeability shape: EI lamination Origin: Japan Noble hydrogen annealing: materials can also..... -

Manufacturers wholesale four hundred low-voltage cold-rolled oil-immersed transformer cores

thickness: 0 - 213mm delivery time: 31-45 days model: S20-M-200/10 technology: cold rolled Purpose: transformer Origin: Jiangsu, China type: Oriented silicon steel Surface treatment: coating shape: TL lamination payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram Customization requirements:.... -

Single-phase silicon core UI EI laminated core for transformer

Packaging Details: 25kg/carton, then palletized for EI laminated iron core of EI 66 silicon steel sheet transformer type: Non-oriented silicon steel grade: Silicon steel technology: cold rolled Supply capacity: 50000 pieces per month delivery time: 15-21 days shape: EI lamination process: punching..... -

CRgo Laminate 0.27mm m3 Cold Rolled Grain Oriented Steel for Transformer

Package preview: delivery time: 15 days after payment grade: M3 model: ZZCRGO-17 product name: Transformer silicon steel coil thickness: 0.1 - 0.3 mm type: Oriented silicon steel pricing term: FOB CFR CIF port: Tianjin, Qingdao, Shanghai standard: Aisi payment terms: L/C, Western Union, D/P, D/A,...... -

TSK brand transformer cores are made of Japanese materials to ensure high magnetic permeability and reliable performance.

Packaging Details: Safe and secure packaged in a 45 x 35 x 18 cm cardboard box with dividers port: Tokyo, Yokohama, Narita, Haneda Package preview: thickness: 0.2 - 0.35mm type: Non-oriented silicon steel shape: EI lamination Surface treatment: annealing Supply capacity: 100 kg per month grade:...... -

Laminated silicon steel transformer core, laminated iron steel core

shape: TL lamination standard: ASTM, bs, DIN, JIS Certificate: ISO9001 port: Shanghai technology: cold rolling type: Oriented silicon steel thickness: 0.1 - 0.5mm payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram Origin: China Shanghai grade: Cold Rolled Grain Oriented Steel application:..... -

Electrical silicon steel sheet price, transformer electrical silicon steel sheet, CRGO CRNGO silicon steel sheet

color: grey payment terms: L/C, Western Union, D/P, D/A, T/T, MoneyGram delivery time: 15-21 days Certification: International Organization for Standardization standard: ASTM size: 100*100*80CM Supply capacity: 500 tons per month Material: Silicon steel grade: croatia port: Shanghai port Origin:...... -

Japanese permalloy EI magnetic core is used for magnetic shielding of transformer camera module

model: P3-8 port: Tokyo, Yokohama, Narita payment terms: L/C, T/T, PyaPal type: Non-oriented silicon steel standard: JIS delivery time: 31-45 days shape: EI lamination Origin: Japan grade: JIS Packaging Details: Safe and secure packaged in a 45 x 35 x 18 cm cardboard box with dividers thickness:...... -

Low price power transformer electrical EI silicon oriented steel plate iron core for sale

Material: Cold rolled grain oriented silicon steel brand: Chenglian Supply capacity: 1000 tons per month width: Require port: Shanghai Key words: core lamination standard: ASTM, DIN, JIS Packaging Details: carton or negotiate Origin: Jiangyin, Jiangsu, China payment terms: L/C, T/T thing:......