HT 2200C High Temperature Zirconia Ceramic Fiber Board Factory Price

- $12.00 / >=10 pieces

- 10 pieces

- Zhengzhou Hengtong Furnace Co., Ltd.

- Henan, China

- Ms Richel Cheng

Product Detail

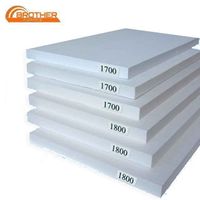

| Operating temperature: | 1050°C 1260°C 1430°C 1600°C 1700°C | size: | 600x300/900x600/1200x1000mm |

| Fiber Diameter: | 3-5 microns | Ultimate Strength (≥MPa): | 0.040~0.075MPa |

| thickness: | 6/10/15/20/25/30/40/50mm | pack: | Carton + pallet |

| width: | 300/600/1000 mm | brand: | HT |

| Classification temperature: | 2200 | chemical composition: | Al2O3+SiO2 |

| length: | 600/900/1000/1200mm | density: | 280-600 kg/m3 |

| Packaging Details: | Cartons and pallets | port: | any port in China |

| Supply capacity: | 100 sets per month | payment terms: | L/C, T/T, Western Union, MoneyGram |

| Shrinkage (1800°F, 3 hours): | 3% (24 hours) | model: | HT-CF02 |

| product name: | High temperature insulation ceramic fiber board | color: | pure white |

| application: | Industrial Furnace Lining | Package preview: | |

| Thermal Conductivity: | 0.18 | grade: | HP (high purity) |

| Origin: | Henan, China |

CCeramic fiber board is a kind of refractory and thermal insulation material. It uses ceramic fiber as the main raw material. After fiber processing and slag removal, a certain amount of binder is added, and it is made into high-strength fiber board through vacuum forming process and drying process.

Ceramic fiberboard is a hard product made of different ceramic fiber blocks with excellent chemical stability. It is processed by wet organic bonding and vacuum forming and is used in various industries.

1. Abrasion-resistant materials on the surface of conveying equipment, such as chutes/hoppers, cyclones, elbows, cyclones, conveyors or pulleys.

2. Wear-resistant materials for petroleum, mining, steel, electric power liquid flow pipelines

3. Anti-chemical corrosion

4. Thermal influence

By offering innovative solutions, Tiles will ensure significant savings in equipment and labor. Our products are used extensively where materials are subject to wear due to abrasion, impact, friction, heat or corrosion.

Ceramic Fiber Board Physical Data

|

Model |

HT-1000 |

HT-1260 |

HT-1400 |

HT-1600 |

HT-1800 |

|

|

Grading temperature |

1000℃ |

1260°C |

1400°C |

1600℃ |

1800°C |

|

|

Density(kg/m3) |

300-700 |

300-700 |

300-700 |

300-700 |

300-700 |

|

|

Reheat linear change (%) |

(800°CX24h)<1 |

(1050°CX24h)<1 |

(1200°CX24h)<1 |

(1500°CX24h)<1 |

(1600°CX24h)<1 |

|

|

chemical composition(%) |

Aluminum oxide |

38 |

42 |

50 |

68 |

85 |

|

Alumina+silica |

96 |

98 |

99 |

99.5 |

99.8 |

|

|

Ferric oxide |

0.2 |

0.2 |

0.2 |

- |

- |

|

Optimizing solutions and product supply for refractory materials in high-temperature industries such as iron and steel, nonferrous metals, petrochemicals, and building materials.

♥ Refractory material engineering design, contracting, consulting, civil engineering design.

♥ Research and development, manufacture and sales of superhard materials.

♥ Research and development, manufacture and sales of export-specific packaging materials.

♥ Refractory material inspection, supervision and arbitration.

♥ Refractory information consultation and service.

♥ Cultivation and cultivation of high-level talents in the refractory industry

Related Products

-

High quality 1200-1800C aluminum ceramic fiber board for thermal insulation

Product Description Ceramic fiber board introduction: Density: 260-320 kg/cubic meter (16-20 lb/cubic foot)Raw material: Ceramic fiber dispersionThickness: 10mm, 20-50mmAsbestos: 100% asbestos-freeFunction: fire resistance, fire prevention, heat preservation SSJD ceramic fiber board is made of...... -

STA high insulation thermal conductivity 1600C 1700C 1800C Kelin alumina ceramic fiber board

Delivery Details: Within 15 days after confirming the order Origin: Henan, China Ultimate Strength (≥MPa): 40 model: STA-HK-1700 Certificate: ISO9001:2000 payment terms: T/T, Western Union Thermal Conductivity: 0.32 W/mq brand: star grade: HA (High Aluminum) Shrinkage (1800°F, 3 hours): -3 chemical.... -

1500C high temperature fireproof fiber ceramic board

Name: 1500C high temperature fireproof fiber ceramic board Shrinkage (1800°F, 3 hours):... -

ORCAS 1700C Polycrystalline Mullite Ceramic Fiber Boards

port: Shanghai/Ningbo/Yiwu Thermal Conductivity: 0.085-0.2 application: refractory type: Ceramic Fiber Insulation Products color: pure white length: 900/1000mm Supply capacity: 100,000 kg per month grade: ST (Standard) model: AK-74 brand: killer whale Packaging Details: Carton/wooden box/pallet...... -

1600C 1700C 1800C Furnace Vacuum Formed Ceramic Fiber Board

density: 450-600 kg/m3 Ultimate Strength (≥MPa): 0.5 length: 600/900/1000/1200 mm application: Industrial Furnace Lining Classification temperature: 1600°C 1700°C 1800°C Fiber Diameter: 3-5 microns brand: shine port: any port in china Origin: Shandong Province, China color: white payment terms:...... -

KINGWOOL ceramic fiber insulation board 1260c 75mm ceramic fiber board for furnace

Package preview: Thermal Conductivity: 0.12-0.20 (w/mk) (600-800C) sample: available Shrinkage (1800℉, 3 hours): -3 (24 hours) Ultimate Strength (≥MPa): ≥0.05 Fiber Diameter: 3-5 microns Material: Aluminum silicate fiber bulk model: IK-CF-017 Operating temperature: 1050°C payment terms: L/C,...... -

Ceramic Fiber Board for Vacuum Forming Parts in High Temperature Furnace

length: 900/1200mm application: Industrial furnace lining, furnace insulation material, refractory material density: 220-450 kg/m3 Origin: Shandong China Packaging Details: Packing 1. Inner plastic bag + outer carton 2. Woven bag 3. Ceramic fiberboard plastic bag Operating temperature: 1000℃...... -

1800C high temperature resistant polycrystalline mullite fiber ceramic fiber board for kiln

Fiber Diameter: 3-5um thickness: 3-100mm Package preview: grade: HA (High Aluminum) Key words: Polycrystalline alumina fiber board manufacturer: Luyang application: Industrial lining product name: High temperature heat insulation alumina fiber board Fiber length (μm): ≥100 Fiber diameter (μm): 3-6..... -

Laboratory furnace and industrial furnace insulation material ceramic fiber board, 1000C -1900C, manufacturers, price list

brand: brother stove Fiber Diameter: 3-5um grade: HP (high purity) density: 450kg/m3 Reburning line shrinkage: (1500℃x6h)... -

1800C aluminum ceramic fiber plate Polycrystalline plate with mullite fiber

Thermal Conductivity: 0.085(400C)/0.132(800C)/0.180(1000C) brand: killer whale grade: HAZ (High Aluminum Zirconium) Fiber Diameter: 3-5um Operating temperature: 1650 chemical composition: Alumina + Silica density: 500-600 size: customer request payment terms: L/C, T/T, Western Union color: pure......