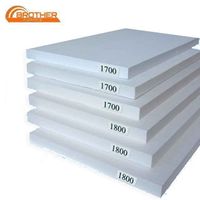

1600C 1700C 1800C Furnace Vacuum Formed Ceramic Fiber Board

- $12.00 / >=100 kilograms

- 100 kilograms

- Shine Technology Co., Ltd.

- Beijing, China

- Ms Nancy Lee

Product Detail

| density: | 450-600 kg/m3 | Ultimate Strength (≥MPa): | 0.5 |

| length: | 600/900/1000/1200 mm | application: | Industrial Furnace Lining |

| Classification temperature: | 1600°C 1700°C 1800°C | Fiber Diameter: | 3-5 microns |

| brand: | shine | port: | any port in china |

| Origin: | Shandong Province, China | color: | white |

| payment terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram, PayPal | chemical composition: | Al2O3+SiO2 |

| width: | 300/600/1000 mm | grade: | HZ (high zirconium) |

| model: | Sinter hardening type | Certificate: | ISO9001:2000 |

| pack: | Carton + pallet | raw material: | ceramic fiber bulk |

| Operating temperature: | 1600-1900℃ | Thermal Conductivity: | 0.135 |

| Shrinkage (1800°F, 3 hours): | 3%(1000℃) | thickness: | 10-50 mm |

| Packaging Details: | Standard export carton and wooden pallet | Supply capacity: | 1500 tons per month |

1600C 1700C 1800C 1900C Furnace Vacuum Formed Ceramic Fiber Board

feature:

l Low thermal conductivity, low heat capacity, excellent thermal insulation performance.

l Good high temperature stability, thermal shock resistance

l Good tensile strength.

l Corrosion resistance.

l Excellent sound absorption, fire prevention and chemical corrosion resistance.

application:

Ceramic fiber products are mainly used as ceramic fiber linings for industrial furnaces, heating equipment and high-temperature pipelines.

Metallurgical industry:Heating furnace, heat treatment furnace, ladle insulation cover.

Machinery Industry:Thermal insulation materials for electric boilers, gas turbines, and nuclear power plants.

Petrochemical industry:Lining of high-temperature reaction equipment and heating equipment in the chemical industry, such as converters, constant pressure/decompression furnaces, cracking furnaces, and flue linings.

Ceramics and electroceramics:Roller kiln, tunnel kiln, shuttle kiln and other kilns.

type | SN-1600 | SN-1700 | SN-1800 |

Grading temperature (℃) | 1600 | 1700 | 1800 |

Density(kg/m3) | 300-600 | 450-700 | 550-700 |

Line Change (%) | 1500℃×24 hours ≤1 | 1550℃×24 hours ≤1 | 1600℃×24 hours ≤1 |

Thermal conductivity (W/mk) | 1200℃≈0.25 | 1300℃≈0.37 | 1400℃≈0.45 |

aluminum2oxygen3(%) | 68-70 | 75-78 | 80-83 |

silica2(%) | 30-32 | 22-25 days | 17-20 days |

Zirconia2(%) | ------ | ------ | ------ |

iron2oxygen3(%) | -------- | ---- | -------- |

Packing: standard export carton and wooden pallet

Shipping: By ship or other ways according to customer's requirement.

1. Timely response,

Reply to your inquiries in a timely manner, make multi-choice recommendations according to your needs, quickly reply to emails and provide solutions.

2. Sample evaluation

Accept to provide samples and trial orders for quality evaluation.

3. Strict quality control

Arrange production on time and strictly control quality.

4. Short delivery time

Book the earliest ship or plane to guarantee delivery time.

5. Professional and complete shipping documents

Provide all detailed news and pictures from order to delivery;

Provide relevant export documents and original certificates when necessary;

6. Warm and thoughtful after-sales service

Related Products

-

High quality 1200-1800C aluminum ceramic fiber board for thermal insulation

Product Description Ceramic fiber board introduction: Density: 260-320 kg/cubic meter (16-20 lb/cubic foot)Raw material: Ceramic fiber dispersionThickness: 10mm, 20-50mmAsbestos: 100% asbestos-freeFunction: fire resistance, fire prevention, heat preservation SSJD ceramic fiber board is made of...... -

STA high insulation thermal conductivity 1600C 1700C 1800C Kelin alumina ceramic fiber board

Delivery Details: Within 15 days after confirming the order Origin: Henan, China Ultimate Strength (≥MPa): 40 model: STA-HK-1700 Certificate: ISO9001:2000 payment terms: T/T, Western Union Thermal Conductivity: 0.32 W/mq brand: star grade: HA (High Aluminum) Shrinkage (1800°F, 3 hours): -3 chemical.... -

1500C high temperature fireproof fiber ceramic board

Name: 1500C high temperature fireproof fiber ceramic board Shrinkage (1800°F, 3 hours):... -

ORCAS 1700C Polycrystalline Mullite Ceramic Fiber Boards

port: Shanghai/Ningbo/Yiwu Thermal Conductivity: 0.085-0.2 application: refractory type: Ceramic Fiber Insulation Products color: pure white length: 900/1000mm Supply capacity: 100,000 kg per month grade: ST (Standard) model: AK-74 brand: killer whale Packaging Details: Carton/wooden box/pallet...... -

HT 2200C High Temperature Zirconia Ceramic Fiber Board Factory Price

Operating temperature: 1050°C 1260°C 1430°C 1600°C 1700°C size: 600x300/900x600/1200x1000mm Fiber Diameter: 3-5 microns Ultimate Strength (≥MPa): 0.040~0.075MPa thickness: 6/10/15/20/25/30/40/50mm pack: Carton + pallet width: 300/600/1000 mm brand: HT Classification temperature: 2200 chemical...... -

KINGWOOL ceramic fiber insulation board 1260c 75mm ceramic fiber board for furnace

Package preview: Thermal Conductivity: 0.12-0.20 (w/mk) (600-800C) sample: available Shrinkage (1800℉, 3 hours): -3 (24 hours) Ultimate Strength (≥MPa): ≥0.05 Fiber Diameter: 3-5 microns Material: Aluminum silicate fiber bulk model: IK-CF-017 Operating temperature: 1050°C payment terms: L/C,...... -

Ceramic Fiber Board for Vacuum Forming Parts in High Temperature Furnace

length: 900/1200mm application: Industrial furnace lining, furnace insulation material, refractory material density: 220-450 kg/m3 Origin: Shandong China Packaging Details: Packing 1. Inner plastic bag + outer carton 2. Woven bag 3. Ceramic fiberboard plastic bag Operating temperature: 1000℃...... -

1800C high temperature resistant polycrystalline mullite fiber ceramic fiber board for kiln

Fiber Diameter: 3-5um thickness: 3-100mm Package preview: grade: HA (High Aluminum) Key words: Polycrystalline alumina fiber board manufacturer: Luyang application: Industrial lining product name: High temperature heat insulation alumina fiber board Fiber length (μm): ≥100 Fiber diameter (μm): 3-6..... -

Laboratory furnace and industrial furnace insulation material ceramic fiber board, 1000C -1900C, manufacturers, price list

brand: brother stove Fiber Diameter: 3-5um grade: HP (high purity) density: 450kg/m3 Reburning line shrinkage: (1500℃x6h)... -

1800C aluminum ceramic fiber plate Polycrystalline plate with mullite fiber

Thermal Conductivity: 0.085(400C)/0.132(800C)/0.180(1000C) brand: killer whale grade: HAZ (High Aluminum Zirconium) Fiber Diameter: 3-5um Operating temperature: 1650 chemical composition: Alumina + Silica density: 500-600 size: customer request payment terms: L/C, T/T, Western Union color: pure......