Refractory ceramic fiber insulation materials 2000 degrees Celsius heat resistant plate

-

$3.35 / 100 - 999 kilograms

$2.19 / 1000 - 9999 kilograms

$1.09 / >=10000 kilograms - 100 kilograms

- Gongyi Hongda Furnace Charge Co., Ltd.

- Henan, China

- Ms Anny wang

Product Detail

| Shrinkage (1800°F, 3h): | -3 (24 hours) | product name: | heat resistant board |

| Fiber Diameter: | 3~4.5um | Cold pressed strength: | 0.12~0.2MPa |

| Ultimate strength (≥ MPa): | 0.5 | density: | 250-500kg/m3 |

| place of origin; place of origin: | Henan, China | type: | Ceramic fiber insulation board |

| pack: | carton + pallet | length: | 900/1000/1200mm |

| model: | XWB | Operating temperature: | 900~1800 |

| feature: | low thermal conductivity | Thermal Conductivity: | 0.085-0.180w/mk(400-1000C) |

| application: | adiabatic | Packaging Details: | 2000 degrees Celsius refractory ceramic fiber insulation material heat resistant board export packaging: 1. Inner plastic bag 2. Carton packaging on pallets |

| chemical composition: | Al2O3, SiO2 | grade: | ST (Standard) |

| brand: | HTC | thickness: | 13~100mm |

| payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram,cash | port: | Tianjin Port, Qingdao Port, Shanghai Port |

| color: | white | Operating temperature: | 1260 |

| Raw materials: | ceramic fiber block | width: | 600/1000mm |

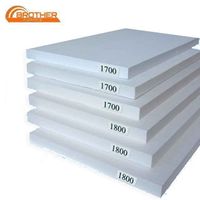

| Classification temperature: | 1050/1260/1350/1430/2000 | Supply capacity: | 10000 kg per week |

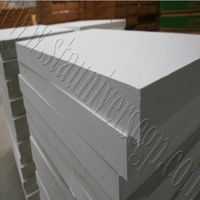

2000 degrees Celsius refractory ceramic fiber insulation material heat resistant board

What is ceramic fiberboard?

2000 degrees Celsius refractory ceramic fiber insulation material heat resistant boardRigid solutions for thermal insulation of industrial furnaces. The panels are fabricated by a wet-forming process using alumina-silica fibers and a binder. Standard plate grades are Standard, High Purity and Zirconia. Circuit boards are available in a variety of temperature ratings, sizes, and custom vacuum-formed shapes. If you are looking for a board not listed or custom fabrication, please contact us directly.

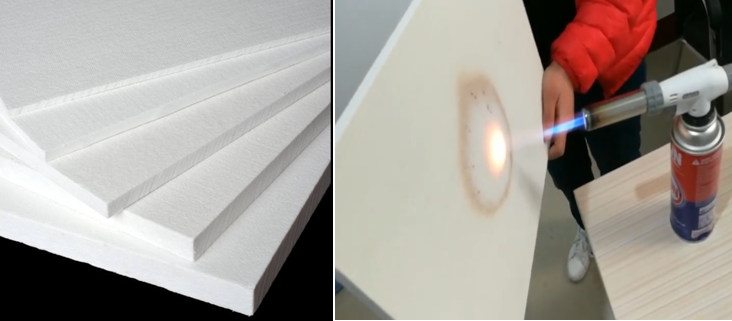

2000 degrees Celsius refractory ceramic fiber insulation material heat resistant boardThe best solution for your high temperature insulation. A mixture of refractory fibers and binders with low organic content is vacuum processed into high temperature ceramic fiberboards with good mechanical strength even after heating. Ceramic plate is a refractory plate with low thermal conductivity and high tensile strength, as well as excellent resistance to thermal shock and chemical attack. On initial use at certain temperatures, the organic binder will burn and brown the board with a slight odor. Once the adhesive is burned off, it will be pure white and odorless.2000 degrees Celsius refractory ceramic fiber insulation material

ceramic fiberboard |

||||

| type | standard | High aluminum | Zircon | |

|

Classification temperature (°C) |

1260 | 1360 | 1430 | |

| Operating temperature (°C) | 1050 | 1200 | 1350 | |

| color | pure white | pure white | pure white | |

| Density (kg/m3) | 250-400 | 250-400 | 250-400 | |

| Heating shrinkage (%) (24 hours, density is 128/m3) | -3 (1000°C) | -3 (1200°C) | -3 (1350°C) | |

|

Various thermal conductivity Temperature(w/mk) |

(1000°C) | (1000°C) | (1000°C) | |

|

Compressive strength (Mpa) |

0.5 | 0.5 | 0.5 | |

| chemical composition(%) | AL2O3 | 46 | 52-55 | 39-40 |

| AL2O3+SiO2 | 97 | 99 | - | |

| AL2O3+SiO2+Zirconia | - | - | 99 | |

| Zirconia | - | - | 15-17 | |

| Fe2O3 | <1.0 | 0.2 | 0.2 | |

| Na2O+k2O | ≤0.5 | 0.2 | 0.2 | |

|

Dimensions (mm) |

usual format: 600*400*50 900*600*50 1200*600*50 Support customization |

|||

Note: Specification parameters can be customized according to your actual requirements.

Shipping and Packagingheat resistant board

1. Our packing is according to customer's request.

2. General cargo by sea.

3. Express sample shipping.

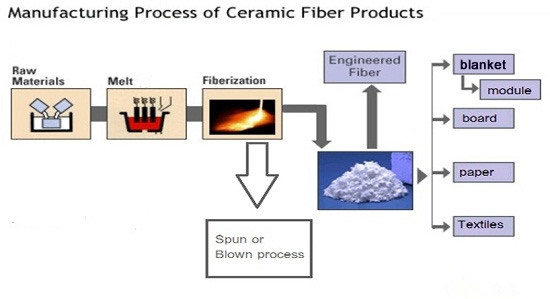

The traditional production process is vacuum forming technology. Using blown ceramic fiber as raw material, adding a certain proportion of binder and filler grade additives, it is fully dispersed into a mud pool. It is put into the forming tank with a pump and stirred with compressed air. Put the mold into the forming pool, and use the principle of vacuuming to make the fiber slurry adsorb on the mold. Accurately control the adsorption time, dehydrate the wet fiber material in vacuum, and put it in a tray oven to dry for 10-24 hours. After the fiberboard is dried by a special grinder and trimmer, the size is controlled. 2000 degrees Celsius refractory ceramic fiber insulation material

HTC adopts an automated production process. Compared with the traditional production process, HTC ceramic fiberboard has obvious advantages:2000 degrees Celsius refractory ceramic fiber insulation material heat resistant boardCompared with ceramic fiberboard produced by traditional production process, it has higher stability, better flatness and more precise dimensions. In addition, HTC adopts automatic constant temperature drying line, which is faster and deeper. The deep drying is completed in 2 hours, the drying is uniform, and the quality is good. Compared with the ceramic fiber board of the same density in the traditional production process, the compressive strength and bending strength are increased by 5%.

With the healthy and rapid development of the company, our The products have been sold all over the country and exported to Vietnam, India, Pakistan, Kazakhstan and other Southeast Asian countries and regions.

Gongyi Hongda Charge Co., Ltd.The purpose of the enterprise is: "Quality first, reputation first, customer first: is our purpose." Scientific management, strong technical force, perfect testing methods, advanced process equipment, and stable product quality are the guarantees of high-quality service. .

Related Products

-

High quality 1200-1800C aluminum ceramic fiber board for thermal insulation

Product Description Ceramic fiber board introduction: Density: 260-320 kg/cubic meter (16-20 lb/cubic foot)Raw material: Ceramic fiber dispersionThickness: 10mm, 20-50mmAsbestos: 100% asbestos-freeFunction: fire resistance, fire prevention, heat preservation SSJD ceramic fiber board is made of...... -

STA high insulation thermal conductivity 1600C 1700C 1800C Kelin alumina ceramic fiber board

Delivery Details: Within 15 days after confirming the order Origin: Henan, China Ultimate Strength (≥MPa): 40 model: STA-HK-1700 Certificate: ISO9001:2000 payment terms: T/T, Western Union Thermal Conductivity: 0.32 W/mq brand: star grade: HA (High Aluminum) Shrinkage (1800°F, 3 hours): -3 chemical.... -

1500C high temperature fireproof fiber ceramic board

Name: 1500C high temperature fireproof fiber ceramic board Shrinkage (1800°F, 3 hours):... -

ORCAS 1700C Polycrystalline Mullite Ceramic Fiber Boards

port: Shanghai/Ningbo/Yiwu Thermal Conductivity: 0.085-0.2 application: refractory type: Ceramic Fiber Insulation Products color: pure white length: 900/1000mm Supply capacity: 100,000 kg per month grade: ST (Standard) model: AK-74 brand: killer whale Packaging Details: Carton/wooden box/pallet...... -

1600C 1700C 1800C Furnace Vacuum Formed Ceramic Fiber Board

density: 450-600 kg/m3 Ultimate Strength (≥MPa): 0.5 length: 600/900/1000/1200 mm application: Industrial Furnace Lining Classification temperature: 1600°C 1700°C 1800°C Fiber Diameter: 3-5 microns brand: shine port: any port in china Origin: Shandong Province, China color: white payment terms:...... -

HT 2200C High Temperature Zirconia Ceramic Fiber Board Factory Price

Operating temperature: 1050°C 1260°C 1430°C 1600°C 1700°C size: 600x300/900x600/1200x1000mm Fiber Diameter: 3-5 microns Ultimate Strength (≥MPa): 0.040~0.075MPa thickness: 6/10/15/20/25/30/40/50mm pack: Carton + pallet width: 300/600/1000 mm brand: HT Classification temperature: 2200 chemical...... -

KINGWOOL ceramic fiber insulation board 1260c 75mm ceramic fiber board for furnace

Package preview: Thermal Conductivity: 0.12-0.20 (w/mk) (600-800C) sample: available Shrinkage (1800℉, 3 hours): -3 (24 hours) Ultimate Strength (≥MPa): ≥0.05 Fiber Diameter: 3-5 microns Material: Aluminum silicate fiber bulk model: IK-CF-017 Operating temperature: 1050°C payment terms: L/C,...... -

Ceramic Fiber Board for Vacuum Forming Parts in High Temperature Furnace

length: 900/1200mm application: Industrial furnace lining, furnace insulation material, refractory material density: 220-450 kg/m3 Origin: Shandong China Packaging Details: Packing 1. Inner plastic bag + outer carton 2. Woven bag 3. Ceramic fiberboard plastic bag Operating temperature: 1000℃...... -

1800C high temperature resistant polycrystalline mullite fiber ceramic fiber board for kiln

Fiber Diameter: 3-5um thickness: 3-100mm Package preview: grade: HA (High Aluminum) Key words: Polycrystalline alumina fiber board manufacturer: Luyang application: Industrial lining product name: High temperature heat insulation alumina fiber board Fiber length (μm): ≥100 Fiber diameter (μm): 3-6..... -

Laboratory furnace and industrial furnace insulation material ceramic fiber board, 1000C -1900C, manufacturers, price list

brand: brother stove Fiber Diameter: 3-5um grade: HP (high purity) density: 450kg/m3 Reburning line shrinkage: (1500℃x6h)...